How does conventional high helix thread compare to dryspin® technology?

Did you know that igus® manufacture a type of high helix thread lead screws? And more importantly, did you know that we have our own patented lead screw technology? No? Then read on. Yes? Then you should still read on!

So, what is dryspin® technology? And what advantages does it offer compared to a conventional high helix thread?

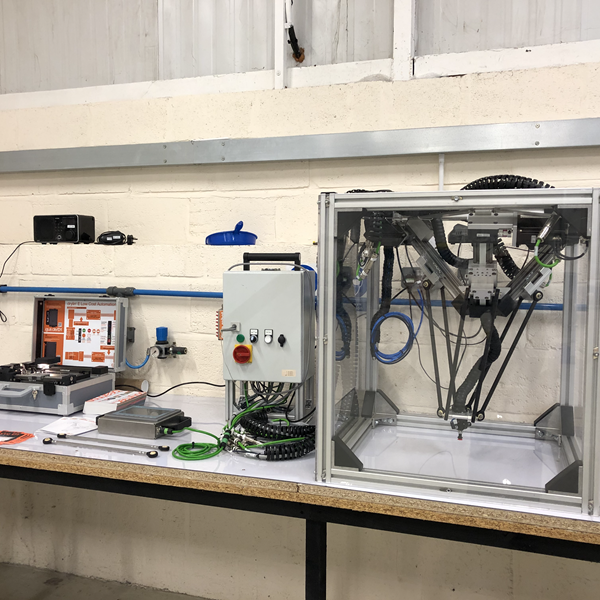

dryspin® lead screw technology was developed and patented in 2016 by the drylin® lead screw technology development team. The goal for these lead screws was to increase service life and improve efficiency, whilst offering a configurable solution from stock.

The portfolio includes high helix lead screws made from stainless steel or aluminium. We have a variety of matching lead screw nuts made from our igus® high-performance iglidur® polymers which go towards the same goals; increase service life and improve efficiency. The drypsin® lead screws are available in pitches from 2.4mm to 100mm, and the range is ever expanding.

What advantages does it offer compared to a conventional high helix thread?

The dryspin® high helix thread geometry is an extension of conventional thread technologies such as metric and trapezoidal threads. In contrast to conventional lead screw geometries, dryspin® lead screw technology is superior due to a number of advantages:

- Higher effectiveness

- Low-noise and low-vibration operation

- Longer service life due to asymmetry

- Reduced wear

- Higher efficiency

In contrast to a metric or trapezoidal thread, the dryspin® high helix thread has a higher pitch. This means that a small rotary movement on the screw is converted into a relatively large linear movement during one revolution of the lead screw. Efficiencies of up to 82% and a longer service life are achieved compared to conventional metal lead screw drives. Another key advantage is that thanks to igus® technologies, both lead screw and nut are dry running, enabling a clean and dry operation without dust and dirt contaminating the system and increasing wear.

Read more about dryspin® technology at igus® here.

How is the dryspin® thread different to a standard high helix thread?

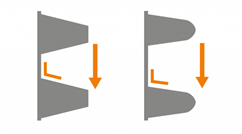

Right: flat flank angle, dryspin® geometry

Left: steep flank angle, standard geometry

The dryspin® lead screws have a flatter flank angle than conventional high helix threads. This allows the lead screws to efficiently convert the applied force into a translatory movement. If you compared this to a steeper flank angle, the loss of force would be lower.

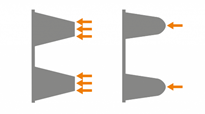

Left: angular toothed flanks, standard geometry

Right: round tooth angles, dryspin® geometry

Due to the rounded tooth geometry, the contact surface between the lead screw nut and the lead screw is reduced. With conventional lead screws, there is a greater contact of two surfaces moving against one another, which creates more vibration and can create a squeaking noise. The rounded teeth on the dryspin® lead screws minimise this effect and the thread moves vibration-free and virtually silently.

To conclude, the dryspin® thread is quieter, more efficient and increases service life over conventional lead screws, so change your lead screw today!