What is the difference between iglidur® and metal rolled bearings?

Customers contact igus® daily and ask if we sell metal rolled bushes. The simple answer is no we don’t. We sell something better. We sell igus® bearings! Controversial I know but with over 50 years of expertise under our belt, we have complete faith in the igus® products. So, let me explain some of the key differences that make the igus® bearings far superior to the metallic PTFE steel rolled version.

How are these bearings are constructed?:

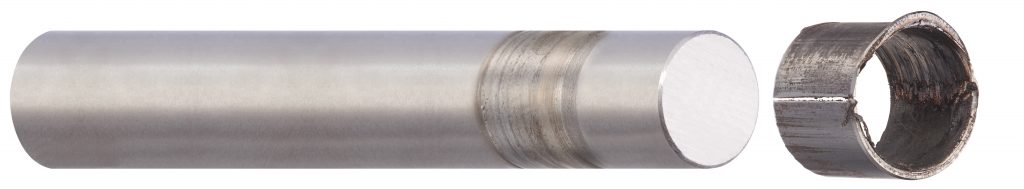

- Steel rolled bearings are described as “metal polymer bearings.” This is as a result of a layering effect. These layers have a steel backing, a bronze layer and a very thin (~0.1mm) polymer layer of some description. This can be either a thermo plastic or PTFE-based polymer. Once the polymer layer becomes worn, the bearing is then running with metal on metal. This could result in shaft damages or catastrophic “seizing up” of the bearing.

- With igus® polymer bearings you have one homogenous component. iglidur® plain bearings have solid lubricants evenly distributed in the material. This ensures low friction and a long service-life at all times. This is achieved through the composition of the plastic compounds, such as; the entire wall thickness of the plain bearing serves as a potential wear surface. Reinforcing fibres enable an additional improvement of the mechanical properties and ensure that the bearings withstand even high loads.

No minimum order or value

Many companies have a minimum order quantity or value. Neither does igus® . As an inclusive company, it is important that every individual and large business gets what they need from igus®.

Material availability

igus® has an extensive range of different materials. A variety of applications can therefore be explored for the most suited material. The steel rolled type bearings come in different sizes but overall appear to have limited material choices.

Can the bearings predict the lifetime?

- Unlike steel rolled bushes, igus® can predict the life cycle of the bearings due to its linear wearing nature. This life span can be determined through a lifetime calculator. igus® also has smart plastic technology which allows customers to be aware if bearings do start to show wear before they become problematic. If parameters change within an application, the smart technology informs the control room that the bearings are wearing before they cause a breakdown.

- igus® bearings are a lot lighter weight wise in comparison to the metal counterparts which is more efficient for the machine and increasing the life of the machine.

- Comparing the sustainability of igus® bearings compared to steel bearings, the method in which igus® bearings are produced is more sustainable. The fact that there is a recycling process if bearings need replacing and the lack of lubrication and grease required makes the whole process more sustainable. The list is endless and you can read more on the sustainable policies here.

igus® regularly replaces metal bearings with polymer bearings and it is easy to see why customers are making the transition. Gone are the days where the belief is that metal is the better option. People want results, they want security and reliability and with igus® bearings you get all that and a whole support team behind you.