Why is sustainability important and how is igus® contributing?

Discussions around green policies and sustainability are more prominent than ever! It is imperative that conversations surrounding ecological projects continue to be discussed. However simply discussing is not enough. The world needs actions. The issue of a more sustainable world is dominating the media on every available platform.

The nations favourite broadcaster, Sir David Attenborough, was recently welcomed to the social media giant Instagram. He had one aim; to reach more people by promoting climate change. He also talked about green incentives and sustainability. In less than 24 hours he had over 1 million followers! Clearly the topic is one that is important to people.

We cannot afford to underestimate the importance unity. We need to ensure that we as individuals and companies are contributing towards a more sustainable lifestyle.

igus® has already accomplished many sustainable incentives. These continue to contribute towards a better planet. But there is more that can be done! That’s why more “green projects” are being introduced throughout igus® worldwide!

3 new areas of sustainability

Water management

The aim is to reduce water consumption by 60%. This will be accomplished by introducing a new re-cooling system for the extrusion machines. The current systems utilises tap water. But with the new system, we are hopeful of reaching the 60% water reduction.

Energy management

To reduce the energy consumption across the entire Cologne factory.

- igus® has already invested over 8 million euros in replacing old machines with newer machines. This is saving 30% energy in comparison to the older machines. In Cologne, there are approx. 500 moulding machines. 200 new ones and 300 old ones. Therefore replacing the balance of the machines will be an ongoing project!

- In the factory we are testing different lights to see if we can reduce the consumption without it being detrimental to the employees. This is not an easy task!

- Compressed air: This consumes a lot of energy and numerous leakages have been identified across the factory. Over the coming weeks these will be fixed and will lower the energy consumption.

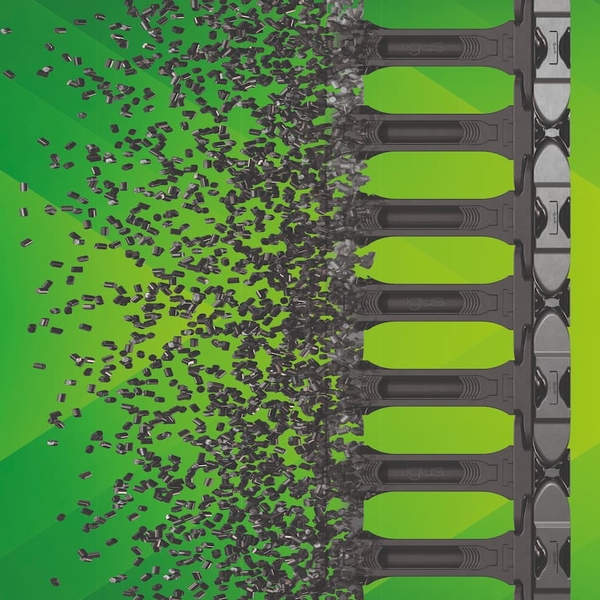

Clean Sweep

Our aim is to reduce the amount of plastic going into the environment. The dream “not to waste a single gram of plastic.” The Clean Sweep is a new incentive to prevent material waste coming off the conveyor belts or moulding machines and becoming contaminated by reaching the floor. Various measures have been developed and have been implemented. These consist of collecting the parts and reducing the number of parts reaching the ground. We will continue to research the optimum method of trying to prevent parts reaching the floor and this will be implemented throughout the factory. By reducing the amount of plastic reaching the floor, we can increase the amount of material we are able to recycle and use for regranulation.

Did you know that it takes 50% less energy to produce plastic over producing steel? So, in theory, as a company, we are already well on our way to helping create a more sustainable world. We already run schemes such as the “chainge” program. This is a way of recycling your energy chains for money off vouchers. We also have investments into chemical recycling of Mura Technology. This technology converts waste into crude oil and this is then recycled into plastic granules. Despite the schemes already in place, igus® will not stop until every aspect of the business is helping towards reducing the environmental impact.

For more blogs relating to sustainability with igus®, visit here.