Will robots take my job?

As the robotics industry continues to grow, so does the uncertainty amongst many workers who fear they will lose their jobs to automation. But how real is this threat? This blog should provide insight from igus® who have integrated automated operations into their own processes, and are becoming increasingly experienced in this field, hopefully putting concerns to rest.

Robots in manufacturing

When focusing on the manufacturing industries, robots are used not to the detriment of any employee but rather to their benefit. When picturing your typical ‘robot’ it’s common to imagine something humanoid and fully capable of any and every task, a near sentient cinematic character. This is not the case, and humans are still integral to them functioning properly.

Benefits of automation

Instead, the typical robot absorbs the responsibility of menial and repetitive tasks that are not complex for employees but are simply time-consuming. For example, drilling, moving, and arranging parts and often functioning as a helping hand to employees.

Cobots (collaborative robots) work alongside humans, designed with safety precautions that give it an awareness of the surroundings using sensors. For example, if the Cobot detects a hand in the way of its own motion, it will stop, unlike other robots that are designed to work independent of interference.

This makes it highly unlikely that robots will take over our jobs as they are created with the intention of assisting a task rather than controlling it. Embracing this automated help does not mean you are suddenly of less use to your company . It rather means you have more time to pursue important tasks and even climb the career ladder!

igus’® attitude

igus® is paving the way to a work environment for manufacturers that benefits from both humans and robots contributing to the success of the business in a cost-effective way. It is within the culture of the business to strive for cost-effective solutions that will allow small and medium enterprises (SMEs) to also benefit from technology that would otherwise feel out of reach.

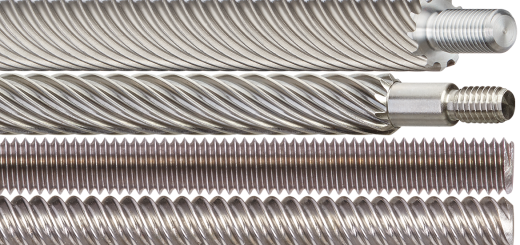

There are compact and neat designs such as the Apiro® SCARA for laboratory applications designed to work without human interference, for tedious and time-consuming tasks so that a workforce can focus on more complex processes. Also, igus® makes other systems such as the triflex range which prevents cable failure on robotics and can be seen being used on the robots from this article! igus® offers the 6-Axis ReBel® which is suitable for industrial and private applications as a cobot or service robot. For more automation information take a look at these blogs.

All igus® products can also be found on the RBTX marketplace where you can filter your search to show specific results and purchase all the necessary parts to have a fully functional machine. If uncertain that this is a step in the right direction, the opportunity to test before you invest is always available to get a solid understanding of what it is you’re buying into!

So how safe is your job?

With all of this in mind, it is plausible that some job roles will become less sought after or necessary with the rise of robotics. However, it’s not likely your job will be taken from you and given to a robot! Many factors such as initial investment cost, perceived value of the products and a pre-conceived distrust of these machines can be a deterrent to many businesses who do not feel these machines are in their company’s best interest.

The main point to note is that humans can provide a wealth of services and real-world understanding that robots simply cannot. Treating robots as a welcome and helpful addition rather than a threat to your own position will allow you to realise that your job role can expand to take on more important and interesting tasks, boosting your own value within your team.