To automate or not to automate?

What is automation?

Automation is a technique, or combination of techniques, that uses electrical equipment to make processes automatic – such as in a car’s transmission.

In the manufacturing industry, automation is a feature of many processes which cannot be performed by a human – due to safety, difficulty or mundanity. This can enable our displaced employees to turn their hand to new and interesting tasks such as service engineering, analysis, project management, and so on.

Today, automation is changing the way we work and also the way we live. It is an approach that many companies and countries have assumed in order to advance in their manufacturing and production processes.

We will now investigate the reasons for and against automation so that by reading this you will be able to make an informed decision about whether to start the steps in adopting automation in your business.

Top 10 reasons to automate

Swaying from the analogue and adopting the digital can prove to be the best move for a business. As more and more companies let go of old-fashioned methods and customs, yet more move towards a more efficient and more prosperous workplace. Below is a list of tasks or applications that can be automated:

1. Tasks that take a long time to perform and may involve overnight and prolonged operation

2. Robots can offer 15 times more strength than humans

3. Robots can offer 10 times more precision than humans

4. Where humans are vulnerable to hazards: chemicals, nuclear, dust

5. Robots can reduce the number of staff needed for a single process

6. Repetitive tasks with little change in process, activities that are monotonous and dull

7. Tasks that can be 100% automated, without any human involvement

8. Automation systems are flexible: they can be quickly reprogrammed

9. Where robots can improve quality and reduce defects in production

10. Automation prices are decreasing as labour prices are on the rise

Reasons not to automate

Nevertheless, not every company should automate their processes, not just yet anyway.

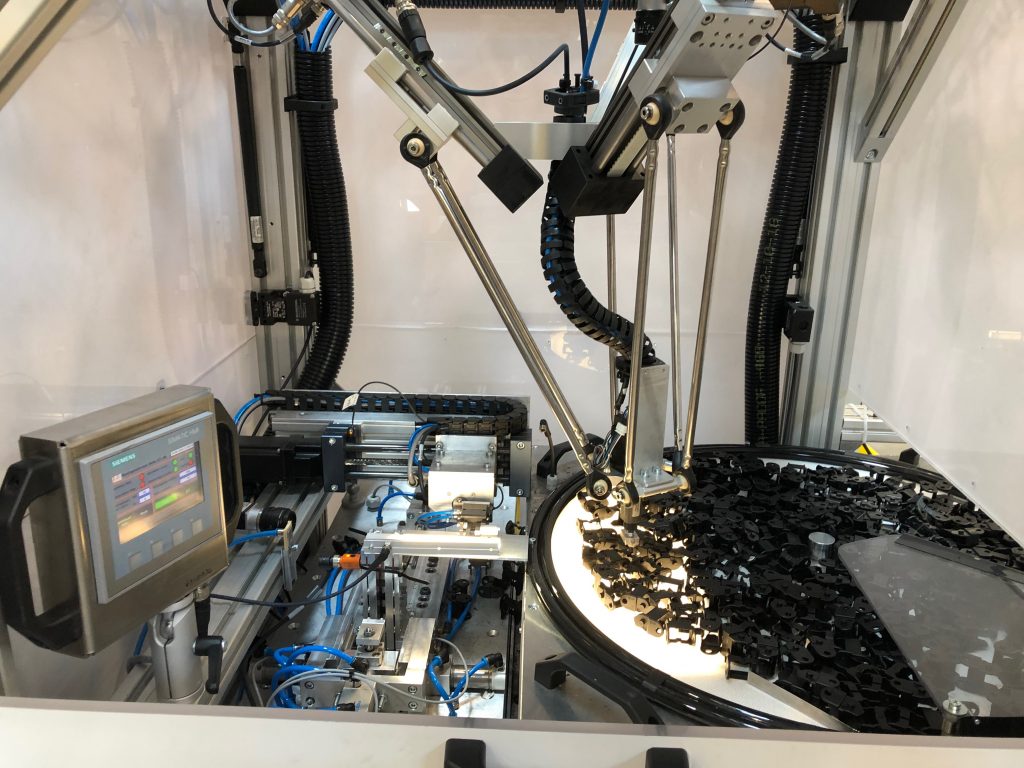

Following the advent of many different types of robots, the development of individual and role-specific robots has grown each year. Consequently, the opportunity to automate a unique task is growing. Not exclusively for difficult tasks but also for dangerous ones such as industrial welding, underwater activities, or chemical production.

However, with regards to holding back from automating, it is important to recognise when a robot or automation system is not the most suitable solution for the job. There are many different robots available on the market, and consequently today’s automation adopters will seek an over-engineered solution to their simple issue. It is important that the solution fits the application. The reason we employ automation is to improve productivity and save costs, rather than have too complex a solution for the task and waste money.

In summary, whether you have already adopted automation or are thinking about it, make sure you research all the options and consider you main objectives for improving your factory. Whether you have high repetition with a desired pick rate, or a low pick rate with extremely heavy components, the solution needs to be right.

When moving humans away from boring, demeaning tasks, we can create more rewarding and fulfilling jobs for them, which in turn will produce a happier workforce. Happy teams increase productivity. Without being radical, adopting automation can expand and improve your business, while relaxing the devotion of key staff and holding onto the more prosperous employees.

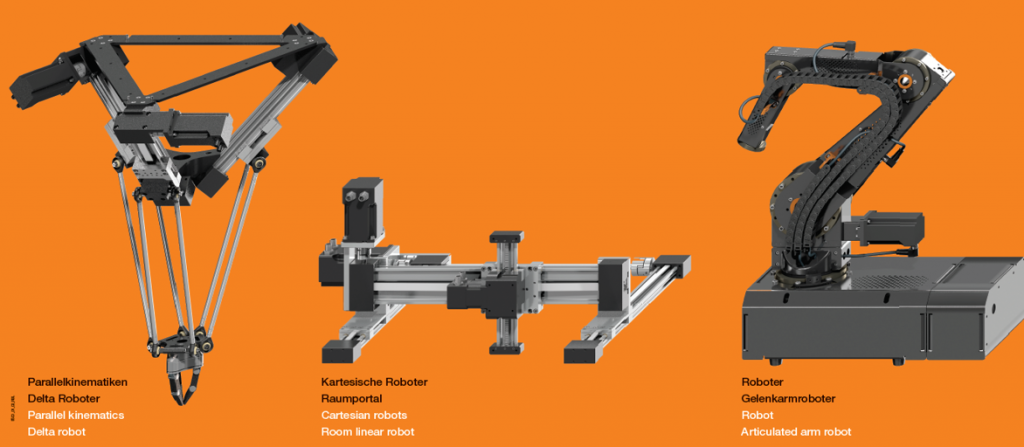

Visit the website to find out more about the igus® gantries, delta robot or robolink®.

Alternatively, contact our Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk for any Low Cost Automation enquiries.