All about the delta robot

What is a delta robot?

A delta robot, or parallel robot, is a 3-axis robot suitable for small working areas and fast applications. Its axes are connected to a shared joint above and below the arms to maintain strength and speed. The first parallel robot was invented in the early 1980s by Professor Raymond Clavel and his team at Ecole Polytechnique Federale de Lausanne (EPFL). The delta robot was created in order to perform repetitive, low-skilled duties such as those found being performed by humans in a chocolate factory at the time: picking and placing pralines into their packaging. Not only were the human fingers melting the confectionary, but it was realised humans did not need to be reduced to such mundane and monotonous tasks.

Since then, many engineering companies have released their versions of the parallel robot, but none as low-cost as the igus® delta robot, and all require joints to be lubricated for the robot to run.

What is the igus® delta robot?

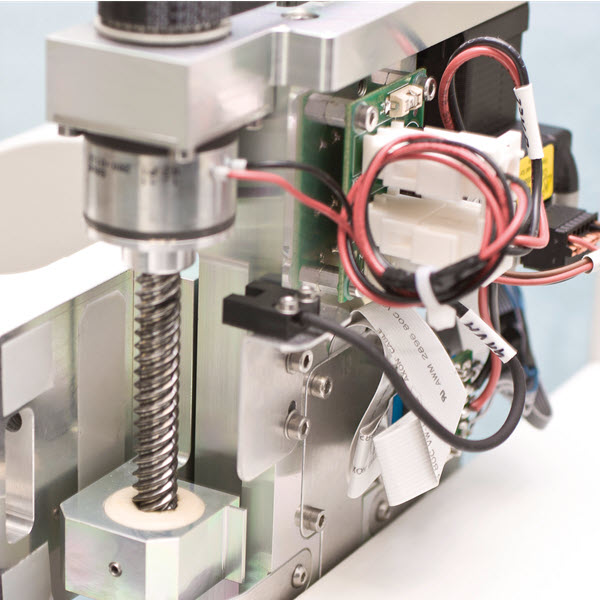

The igus® delta robot is a unique version of the renowned delta robot which uses parts from various areas of the igus® catalogue to achieve fast, self-lubricating, low maintenance solutions for pick and place and many other applications.

Created as an amalgamation of some of the best and most loved igus® products, from the chain and bearing areas of igus®, the igus® parallel robot was released to markets at the Hannover Show in 2018.

Its combination of highly flexible cables, cable management systems, and reinforced belt drives make the igus® delta robot not only unique but also a pioneer in the parallel robot field. The lubricant-free igus® parallel robot needs no typical maintenance and features long-lasting materials which make it perfect for repetitive tasks that use high speeds and high loads.

Our parallel robot is available in both a small and large version. The smaller of the two has a working envelope of 330mm diameter at a height of 75mm. Meanwhile, the large version has double the reach of the smaller robot, and a working area that covers a 660mm diameter at a height of 180mm. The two options allow customers to be flexible with the solutions so that the best robot is employed for their application.

Both versions employ NEMA 23XL stepper motors by igus®, and 3 dryve® D1 motor controllers to direct the logic of the motor on each axis.

Get in touch to find out which version would best suit your application and go through the specification of the delta robot before placing your order.

3D CADs and information sheets of both sizes can be downloaded from the website here.

Read more of our blogs on similar topics here.

Alternatively, contact our Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk for any delta robot enquiries.