Why use a cable drum in a refrigeration lorry?

How is a cable drum relevant to delivery lorries? Sometimes we don’t think about how things are, for example, how do companies keep their refrigerated delivery lorries cool? I had never even considered how this was achieved until recently when an igus® product specialist asked me to write this blog.

Why would I have thought about it? It has no bearing on my life, and yet I work for the company that helps keep people’s shopping deliveries cool.

But consider this…. you cannot create cold. It is merely an absence of heat, so it needs one self-contained atmosphere and then heat removed… intrigued…

Keeping it cool

So how do we accomplish this? How do we get the power to the lorries to keep them cool?

Fundamentally, the principle is this:

- Coolant fluid is added to pipework which circulates around the container, sucking up the heat.

- The coolant captures the heat and is turned into a gas in the evaporator.

- The gas is then released into a compressor which compresses the gas under extreme pressure.

- A machine then condenses the gas to a liquid in a condenser, transferring heat to the outside atmosphere.

- This process is then repeated, gradually making the lorry colder and colder.

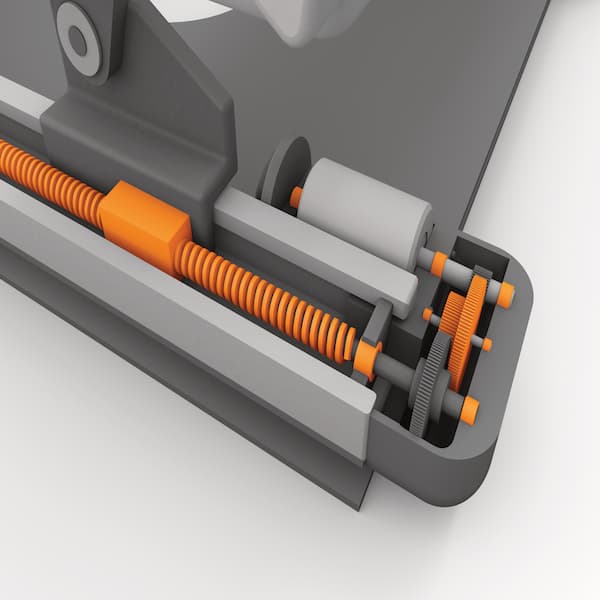

But this process needs power, energy and fluids transmitted. How does this happen? One option is using a cable drum, the igus® e-spool® flex!

This is a safe and secure way of delivering power to the lorries without having a trip hazard. There are 3 main points as to why the e-spool® flex is perfect for lorry power.

1 – Health and safety in the loading bay, no cables left dragging along the floor

This type of cable drum can carry all cables and hoses for the transmission of energy, signals, data, liquids, compressed air and vacuum without interruption. Fully harnessed cables can therefore be used, which can be inserted into the drum in a few easy steps. The user simply inserts the cable into the spiral guide and fastens the cable stowed in the outer and winding housing of the e-spool®.

The e-spool® cable drum can be mounted on the wall of the warehouse safely and securely, and when the lorries pull into the dock, the operator can unreel the cable and plug it into the lorry. This can be mounted high off the ground so there are no cables dragging on the ground causing a trip hazard. Once the lorry is ready to go, simply unplug the cable and the reel will retract the cable back in and store it safely out of the way.

2 – Doesn’t have a slip ring like traditional cable reels do which are problematic

Alternative systems that can be used in lorry refrigeration are cable reels which use slip rings for energy and signal transmission in a rotating drum. The downside of these cable drums is that they often are only available as a complete package with a new cable, and a single form of medium being fed through of data or media, therefore, this solution is by no means ideal. The e-spool® flex doesn’t use a slip ring, therefore, the type of cable/hose passing through the system is not as limited. This flexibility allows the operator to have different energy requirements leading to the lorries.

3 – Go Greener – the positive environmental impact

Think about it, how do you think lorries get power to them currently? They leave the lorry engines on! Consider the negative impact the fumes alone are having on the environment! Using the e-spool® cable drum eliminates this issue. As mentioned previously, no cables dragging on the floor, no nasty engine fumes seeping into the atmosphere. Clean and tidy.

Want to find out more about what igus® is doing to go greener? Read all our sustainability blogs now!

Keeping the refrigeration cool safely, environmentally sound and as low maintenance as possible is the dream but we can make it a reality.

Speak to our expert today! Visit our contact page for more information.