How is using polymer bearings in bicycles advantageous?

Bearings in bicycles are not only used for design but also for material selection. There are so many decisions to be made. Take the frame, for example, there are many options to have them produced in aluminium or glass fibre-reinforced material. And ‘why?’ To reduce the weight.

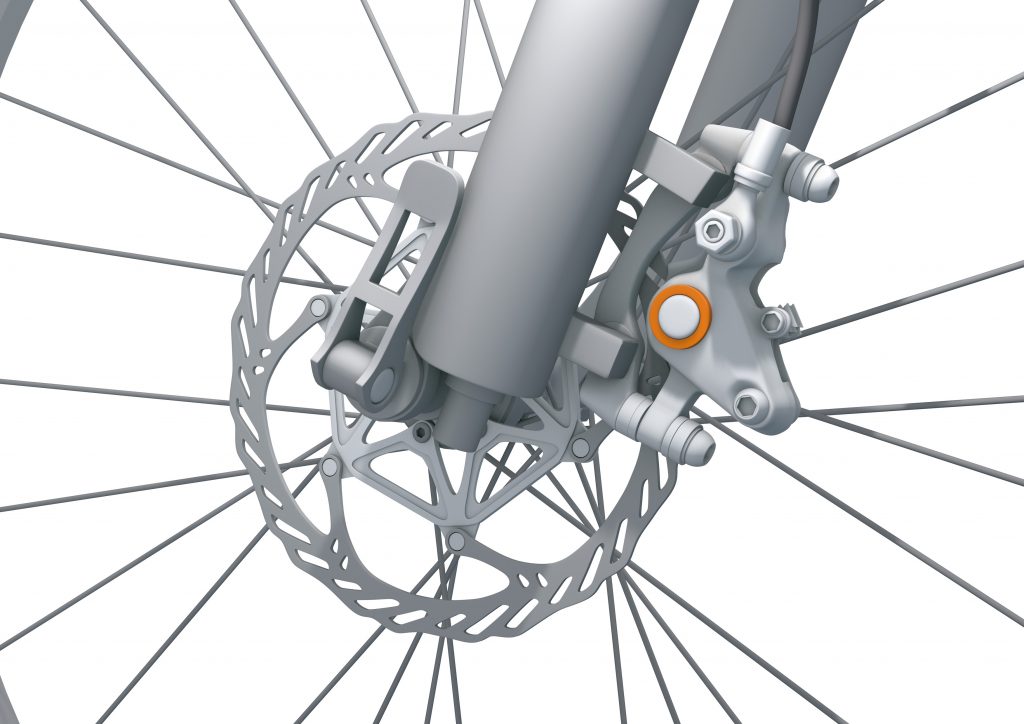

With this in mind, more component manufacturers are turning to alternative materials, such as polymer instead of metallic options. Whether it’s the seat post, suspension, pedals or gearshift, polymer is becoming increasingly evident in applications. Plastic polymer bearings are gaining popularity because they have numerous advantages over metal bearings.

The weight of bearings in bicycles

As previously mentioned, weight is one of the most important points to consider when buying or designing a bike. In the everyday use of a bicycle, it can become problematic when lifting the bicycle up to put into the back of a car or up and over a gate. Furthermore, weight reduction is essential towards marginal gains, especially on road bikes. A polymer bearing from igus® is approximately seven times lighter than a comparable metal plain bearing! When weight is an issue, it is definitely beneficial replacing the metal bearing for a polymer one.

Wear and Life

How many metal bearings do you know that allow you to predict the wear and life cycle of the bearing? This is another critical element for selecting the best materials for the design and production of bikes. If you consider a metal bearing with a PTFE coating, it would soon become apparent that the coating is wearing quickly after coming into contact with dirt and edge loads. It is no longer able to offer the sufficient sliding properties that are required.

The life cycle of these metal coated bearings is reduced enormously. In addition to the reduction in sliding properties, the wear on the coating creates metal-on-metal friction, which can cause the bearing to become noisy and damage the more expensive mating component. With a polymer plain bearing on the other hand, you don’t have the 2 layers, the metal and sliding coating due to the homogenous nature of the material mitigates the risk of catastrophic failure. This enables the bearing to perform throughout the wall thickness of the components creating an ideal running surface, thus, a longer service life is achieved, utilising the entire bearing and not just a coating!

The corrosion of bearings in bicycles

Polymer bearings are corrosion-resistant and offer great advantages in wet environments, which is essential in bicycles! When you consider the terrain that bikes endure, having bearings that are insensitive to impact, shock and being dirt-resistant, are all features that need to be considered and adapted for. Using polymer bearings allows the bike to defy shocks and bumps and be more resistant than with metal counterparts. Moisture can affect metal bearings, but with tribologically optimised polymer bearings, there is no corrosion or decomposition of the bearing.

igus® polymer bearings have all these qualities. With the elimination of external lubricants within igus® materials, maintenance is eliminated, other than a good washdown. This makes the decision when choosing components to utilise in bikes an easy decision. Polymer over metal. Choose igus®

Do you work on your own bike and other DIY projects? Read all our DIY blogs on how to use igus® products within all your DIY projects here.