Can you change drive cable manufacturers?

It is amazing how many fictitious stories we hear about drive cable manufacturers options. There are some rumours surrounding drive cables which can easily be explained or quashed.

One of the biggest rumours that we hear from our customers is, “We HAVE to use the original drive cables of the drive manufacturer”. This is not true. When you think about it, it is a clever ruse by the manufacture to ensure you remain loyal to them….

Here are a few examples explaining whether you can change drive cable manufacturers.

The guarantee claim:

“We must use the manufacturer’s drive cables otherwise this will void any guarantee claims for the drive system.“

The manuals or CE-conformities concerned with this topic deal with FUs, throttles, filters, etc. Cables are not considered. According to component lists, these are not classed as “classic components”. This means that the manufacturer’s guarantee claims run separately from the linking cable. The electrical specifications are fixed. However, these comply with chainflex® cables

Risk management

“We must use the manufacturer’s drive cables for risk management, minimising the number of unknown (cables) products. We know the manufacturer’s parts will work.”

In this risk analysis, cycle times of relays, valves, etc are considered. Safety-relevant maintenance measures and component replacements are calculated based on statistical values. Unfortunately, cycle numbers of dynamic electrical cables are not included in this assessment. This means the risk analysis does not take cables into account. With the igus® chainflex® cables, we are the only cable manufacturer that provides detailed information about service life AND provides a guarantee.

Cable selection by the drive cable manufacturer

“Often only one dynamic and one fixed type of cable is available from the drive manufacturer.“

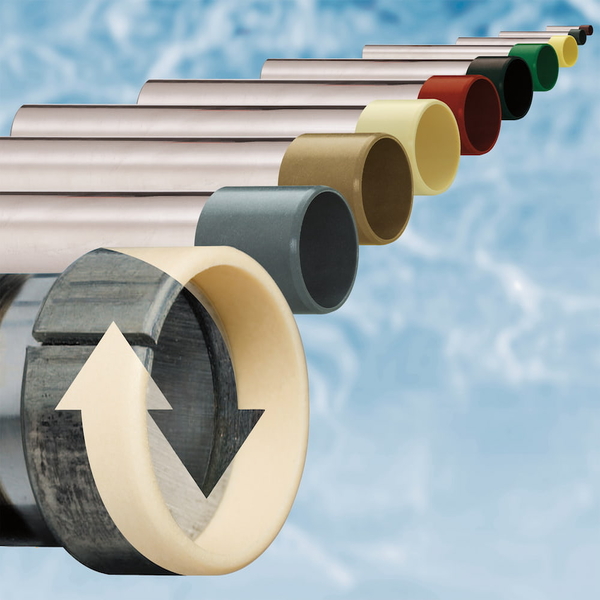

Drive manufacturers do not usually have a wide range of cables for dynamic applications. The focus and core competence IS NOT on cables. This is because the large drive manufacturers have their competence and expertise in the motors and FUs. With this small selection it is impossible to support all highly dynamic applications as well as those with challenging environmental conditions. In situations such as these, special cables designed for motion would need to be specified.

This is where igus® comes in! As cable specialists, igus® can ensure that the correct cables are specified and designed. Not only for performance but also for safety.

Read more about igus® chainflex cables and their design here.

Conclusion

Let’s be clear, the statement about the cancellation of the guarantee promise is not true and cables are often not included in the standards. In many applications however, there is no other solution than to use special cables. The requirements are often very high and cannot be met by standard cables. This is where the advantages that chainflex® offers come into play:

- As assembled cables, available with original connectors of the drive manufacturers

- No minimum order quantities

- No cutting charges

- We give a 100% guarantee on our cables to the drive manufacturer

- More approvals which therefore minimises product variation and inventory values.

- Calculable service life in the planning phase thanks to numerous online tools

- A suitable alternative for every application thanks to up to 7 different product types

The bottom line is, as the customer, you are in control. You need to do what is best for your application and machine to ensure you get the best performance. This is not always using the manufacturer’s parts, therefore, don’t feel obliged that you must do this. igus® can help.