Did you know igus® offers project planning?

Not many customers know that igus® offers project planning. It is something that we have always offered as a “complete package” solution. It is not something that everyone needs, or at least thinks they need but it can save issues down the road if a partnership between ourselves and the customer is established at the beginning of a project.

Mark Smith, Head of Engineering Projects at igus® in the UK gives a little insight into what igus® can offer.

How is the igus® engineering & project planning division helping industries of today?

Having been in the cable management industry for 50 years, igus® has evolved into more than just a manufacturer. We are also problem solvers, consultants and application and industry experts. With our expertise, we can analyse a customer’s application, understand their needs and offer a reliable solution. Whether that be a new design, a retrofit of either an existing energy chain application or switching out alternative technology. This could be a cable reel, busbar, festoon or slip ring. Whatever the system, igus® can provide a cable management solution to suit a customer’s need.

In terms of service, what does igus® bring to the table within project planning?

We see ourselves standing alone in terms of what a supplier like us can offer. Not only do we manufacture complete energy chain systems, but we can closely examine, assess and appraise existing systems. We are then able to design and offer a more reliable or suitable alternative. This comes from using our experience in designing, application knowledge, project planning and industry expertise.

So, you are a design house?

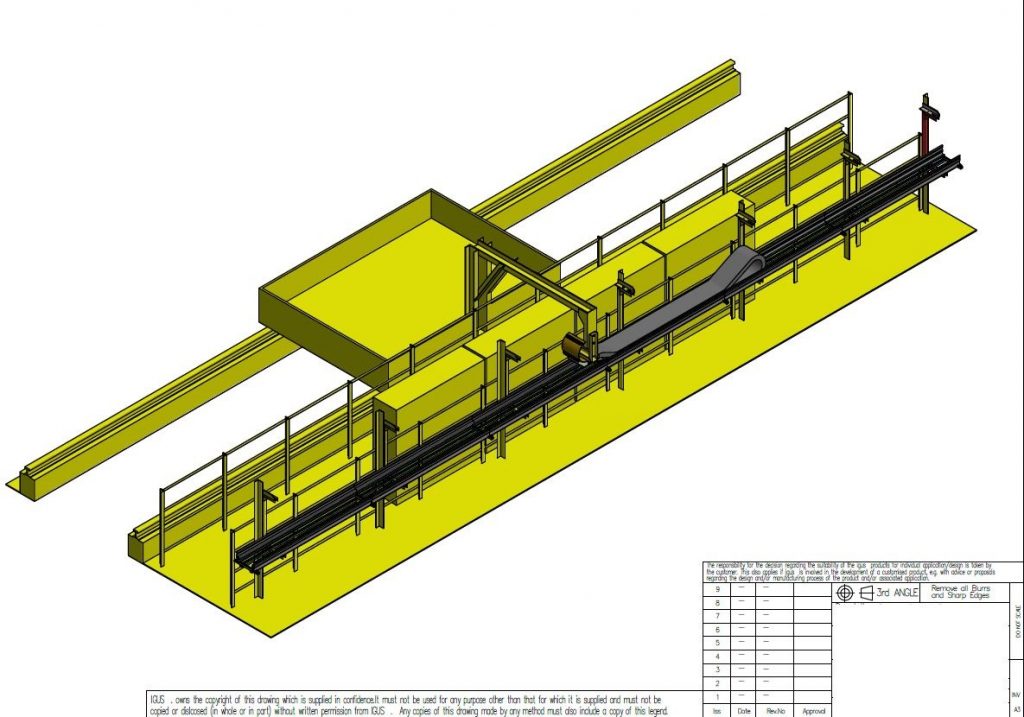

In part, yes. It is our goal to ensure that the parts have been correctly designed into the application and also correctly installed. In the case of retrofits, we carry out the full design. This information can be drawn from various sources, such as customer drawings, on-site testing and measurement taking. This then follows onto design review, approval, manufacturing, QC and shipping.

This is accompanied with all the information required to assist with a successful installation on site, whether we are involved with this part of the project planning or not. We produce a General Arrangement drawing of not just our system but how our system looks on the machine. This comes in the form of a full drawing pack, complete with full BOM information, individual component details, assembly details and installation and testing guidance. The benefit to both ourselves and the customer is that by following this process, the chances of overall success of the project are very high.

What about new designs?

Our service is not limited to retrofits and designs for existing applications. In the case of new machine designs, we find our best success when we work with the customer from the earliest point in the design. If this is not possible, then this can add risk to the project by compromising the final system, which if had involved us, earlier could have been avoided. We always seek to be an integrated partner rather than just a parts supplier.

Tell me more about the project management aspect of your work?

There are many aspects to running a successful project. Our approach to the more complex of these has just been a gradual evolution of our experience. In the last few years, we have adopted many of the principles of the standards set out in established systems such as PRINCE2. We found that we already used many of these principles without even realising. Adopting these methods has helped us evolve into the integrated partner to our customers.

If somebody has an existing cable management problem, what do you offer?

A customer isn’t always aware that they need us – through our pro-active work, we often highlight something where we feel we can help improve reliability or save money or both!

For example, a customer might think that replacing a festoon every 6 months is just historically what happens. We mention that they can have a maintenance -free, long- life system from us through understanding the company, their processes and the application. Once we have established the problem, we can start working on offering a solution.

Read our detailed blog on igus® energy chains versus festoons here.

What on-site capabilities do you have?

We work in a very diverse range of sites – ranging from factory environments, nuclear sites, shipyards, ports, CDM- controlled construction sites and COMAH top tier sites. Planning is crucial and we plan everything where permitted including all SSOW, special access and lifting equipment. We ensure we have all necessary lift plans and procedures in place and are well versed in getting any project or site- specific paperwork in order for our on-site teams. This ranges from: criminal record checks, SQEP documentation and competency information, medical checks, health & safety documentation, such as IPAF licences, working at height, rescue from height training & confined space, with a few of us now issued with BOSIET certificates for working offshore.

What information do you need to work with for project planning?

The data we need to establish a working proposal can be quite significant. The more high-quality information that we receive, the more informed we are and the more accurate our offer can be. Subsequently, the project delivery phase becomes more efficient. We place a strong emphasis on obtaining highly accurate data. Some of this can be done remotely via a video link, especially on new designs. Drawings and specification documents can be shared digitally but in terms of retrofit work, we always prefer to visit site.

Do you have questions about igus®? Read our frequently asked questions here.