What are gantries?

The term “gantry” is used so often but can mean different things to different people. This blog looks at the question, ” what are gantries?” and will identify where they can be used and how they are made.

What are gantries?

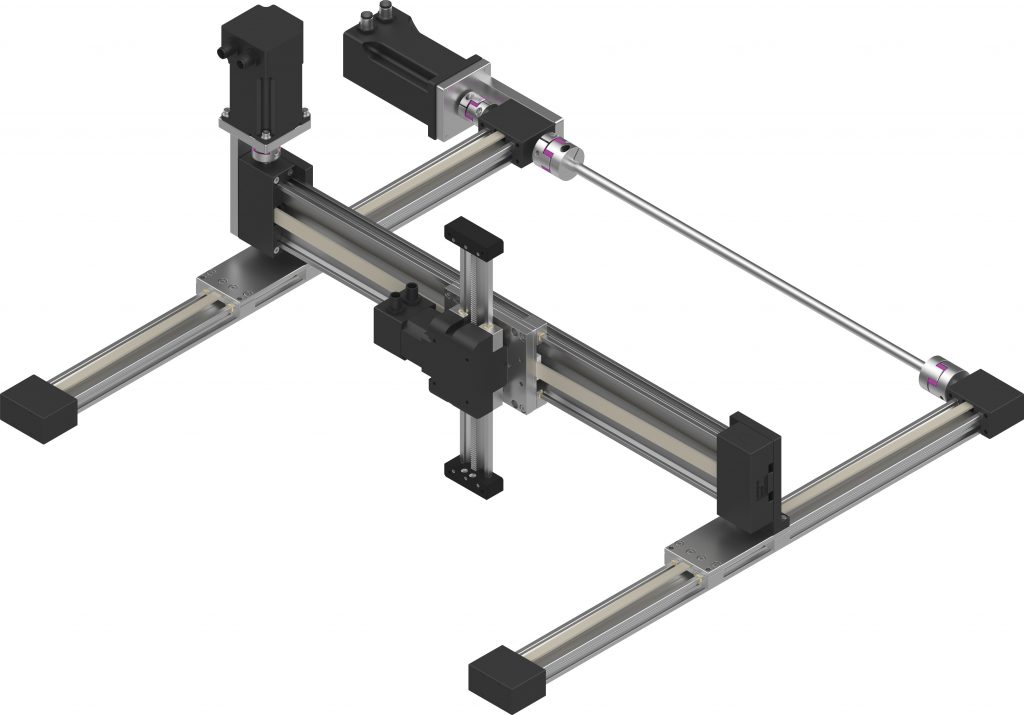

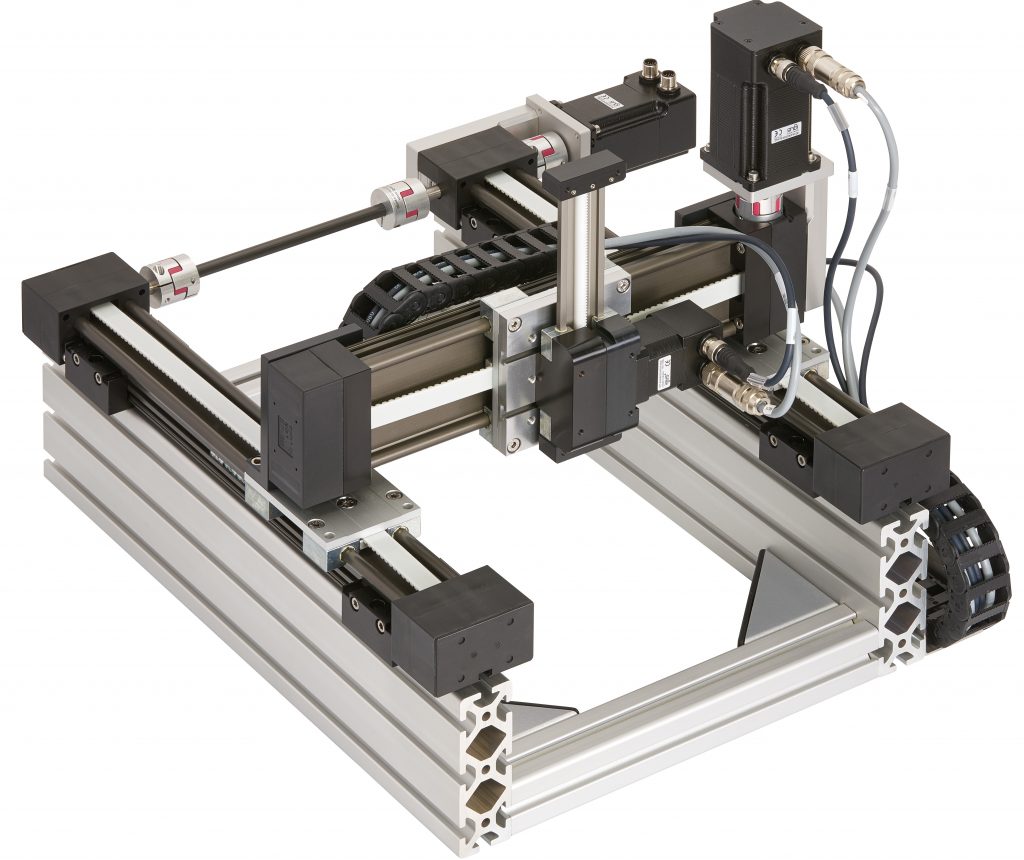

Gantries by definition are merely a platform or structure which can be vertical or horizontal and acts as a frame work to support movement. There are endless modular combinations of axes for gantires and the igus® gantries are no exception.

What options do igus® offer?

With our toothed belt drives, rack and pinion and/or lead screw drives, the flexibility of choice results in a truly bespoke solutions for each application. For a lead screw-driven gantry, the customer can choose from a variety of lead screws: high helix or trapezoidal. You can choose thread direction from: left-hand, right-hand or opposed drive depending on the drive source.

Thread type can also be selected according to the properties required and application needs: high helix, high helix dryspin®, metric, or trapezoidal. In addition, there are over 60 different sizes which will become more focused according to the thread you choose. Materials for our lead screws vary from aluminium to stainless steel. Both lead screw materials work with our tried and tested polymer lead screw nuts to secure dry running, long-life and smooth functioning.

The nuts can also be chosen according to the level of friction coefficient, thread size, and according to the minimum and maximum temperatures of the application. The end blocks feature ball bearings to maintain high speeds alongside the high precision properties of these linear axes. The technology behind our lead screws can be found here. These lead screw units can be further customised in rail size, length, and bearing materials. This ensures the wide-reaching capacity of our lead screw units for multiple industries: from food and beverage to aerospace.

The toothed belt drives are also highly customisable before even starting to construct them in a multiaxial system. The varieties we offer are the basic and the standard belts. A basic toothed belt is made 100% from plastic and is suited to most applications where handling, high frequency automation, and X-Ray systems are in use. Whereas, the standard belt is made of steel-reinforced polyurethane and is suited to extreme conditions such as underwater or in very cold or hot environments.

In addition to the style of gantry, when components are specified for an application, they can also enhance properties such as speed, precision, and load capacity. Available in a modular form and ready for assembly upon delivery or pre-assembled, the igus® gantries represent one of the most interesting product ranges across the company.

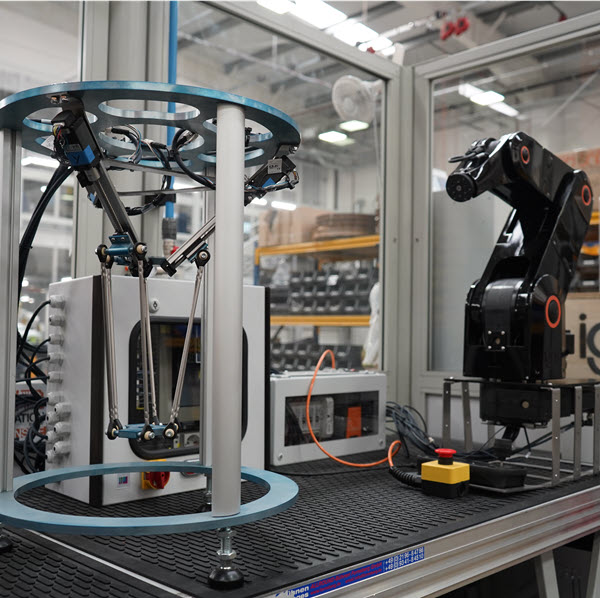

Where are our gantries used?

igus® gantries are used in countless different applications and industries, from underwater camera rigs to industrial laundry services, picking and distributing clothing. The opportunities are endless when it comes to igus® gantries: whether an application requires high speed, high accuracy or high loads, the solution will be found using the igus® gantry options.

Which gantry should be used and where?

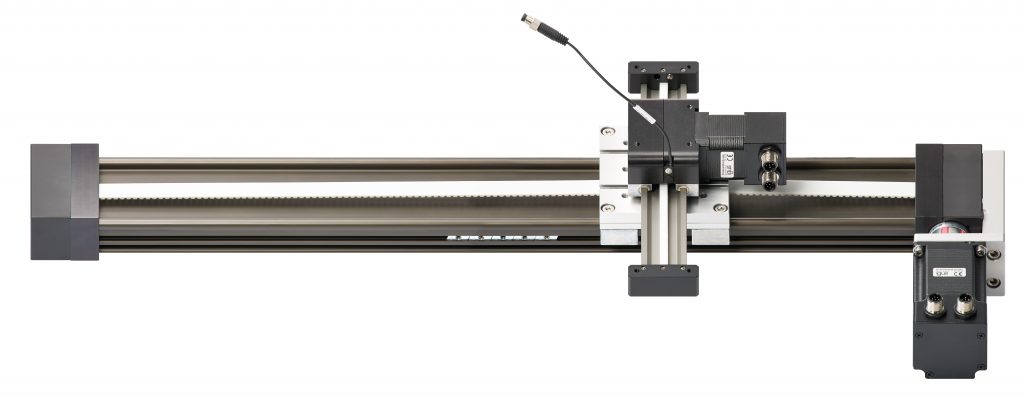

Flat gantries (also known as surface gantries) are suitable for predefined surfaces such as in measuring or repetitive marking tasks. The benefits of this type of gantry are that it features not only easy installation with its kit-form, modular design but also a proximity switch mounting which can be applied at any point across the length of the section.

Meanwhile, room or linear gantries are suitable for three-dimensional applications, and are best for assembling technologies and other simple small-part handling tasks. The benefits of using this gantry is for the unified source feature, where all control originates at the same location and its ready-to-use kit design means the modules can be easily assembled and installed.

Last but not least, line gantries are for tasks on vertical working planes, such as for sorting systems in medical technologies or for picking and placing tasks in warehouses. Some benefits of these include speed and accuracy. With just two axes, this is ideal for fast and long-travel applications too.

Hopefully this will have answered the question, “what are gantries?” given a bit of an insight into the options we offer at igus®.

For more information on our igus® gantries, visit the other blogs https://blog.igus.co.uk/category/low-cost-automation/gantry-linear-robots/