How to calculate downtime in production

In the world of manufacturing and production, downtime is a critical metric that can significantly impact productivity, efficiency, and profitability. Understanding how to calculate downtime in production accurately is essential for identifying areas of improvement and minimising disruptions, but it can be time consuming.

This blog post will guide you through the process of calculating downtime in production, including the types of downtime, the steps involved, and the tools you can use.

Types of Downtime

Before diving into any calculations, it’s important to understand there are different types of downtime:

- Planned Downtime: This involves scheduled maintenance, upgrades, and other planned activities like compliance and audits that require stopping production.

- Unplanned Downtime: This occurs when unexpected failures, such as equipment breakdowns, power outages, or other unforeseen issues stop production. This is a costly issue to deal with.

- Idle Time: This is when production is stopped due to a lack of materials, labour, or other resources.

A Step-by-Step to Calculating Downtime

- Identify and log all downtime events either manually or (preferably) through automated systems. Each event should include the start time, end time, and reason for the downtime.

- Categorise the downtime events into planned, unplanned, and idle time. This helps in understanding the root causes and addressing them effectively.

- To calculate the total downtime, sum up the duration of all downtime events within a specific period and maintain consistent time units (e.g. minutes, hours). The formula is:

Total Downtime = End Time – Start Time. Ensure that the time units are consistent (e.g. minutes, hours).

- Calculating a downtime percentage can help you to better understand the impact of downtime on production. The formula for this is:

Downtime Percentage= Total Downtime / Total Production Time* X 100

*The total production time is the sum of all operational hours within the same period.

5. Finally, use the collected data to analyse any patterns and identify the most common causes of downtime. This can help in prioritising the actions needed to improve.

Tools for Calculating Downtime

There are several tools and software solutions that can assist in tracking and calculating downtime. It’s estimated that the impact of downtime in British manufacturing is worth over £180 billion per year. – The Manufacturer

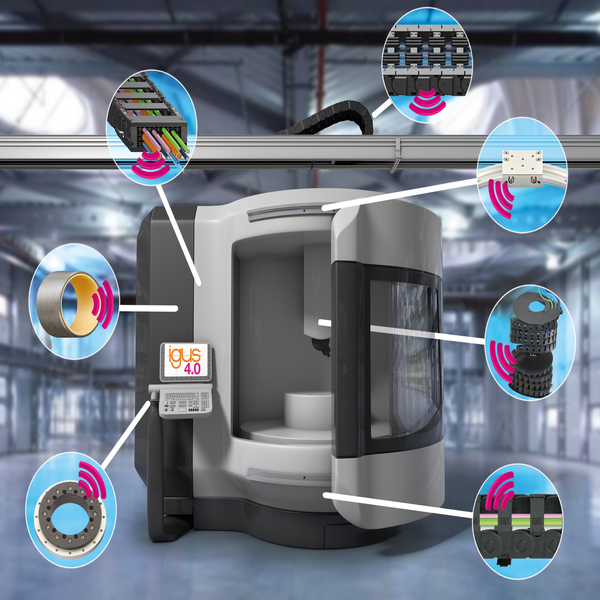

With the continuous condition monitoring systems at igus®, you can keep track of all your systems around the clock, monitoring the equipment health and predicting potential failures, helping to reduce unplanned downtime.

Using i.Sense condition monitoring and i.Cee predictive maintenance helps to track and maintain the health of your equipment and eliminate unplanned downtime, saving vital time and money.

However, these solutions are all designed to be put in place after you’ve purchased your equipment and don’t take into account how to find the right cable with an optimal service life. With the new and improved chainflex service life calculator.

By entering the relevant parameters, you can easily calculate the service life of any chainflex® cable and readycable® before making your purchase. With igus® innovations the tool may even suggest an alternative cable that offers a longer lifespan for your specific application.

Consider the return on investment: opting for a higher quality cable that outlasts others can save you from unexpected maintenance costs due to cable failures. Once you’ve identified the right cable, you’ll receive a 4-year guarantee for added peace of mind.

If you have any questions, contact our chainflex® cable product manager Daisy at ddurrant@igus.co.uk

Best Practices for Minimising Downtime

As unplanned downtime can be so impactful, implementing preventive maintenance schedules can reduce the likelihood of equipment failures. Getting into the habit of ensuring that all employees are trained on proper equipment use and maintenance procedures is crucial and maintaining adequate inventory levels can prevent time wasted to material shortages.

Overall, knowing how to calculate downtime in production, regularly reviewing downtime data and implementing continuous improvement initiatives can address recurring issues and maximise the efficiency of production lines. Read more about igus® innovations here.