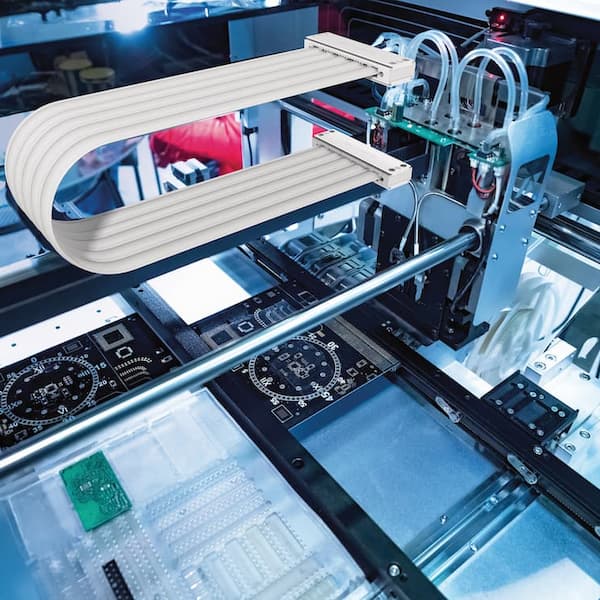

Long travel path – how do I find the right cable?

Long travel distances place high demands on the cable used and its durability. In today’s post, we cover what these are and how we can find out whether our management meets these requirements.

Durability

The topic of durability in cables is a subjective one. Exactly when is a cable stable? A cable is stable for one user if their machine runs for a year without failure, for others the durability of a cable is measured by longer time-frames, cycle amounts, outer jacket degradation and so on.

The construction of a cable has a significant impact on the service life. Especially on long travels, the most important criterion is the careful selection of the correct cable structure.

With the service life calculator, the expected service life of chainflex® cables can be calculated specifically for your application.

Line structure

Countless chapters can be written about the cable structure. On the subject of “long travel”, we would like to take a look specifically at whether we should use the cable with or without an inner jacket.

To make a cable round, we fill the gusset between the cores with filling elements before the shield is braided over it, or before a jacket is extruded over the cores. These “fountain pens”, as they are commonly called, are cheap and serve as placeholders to help make a concentric design.

Durable materials are used in high-quality cables, which help to improve the abrasion resistance of the cable and improve the overall flexing performance. From a certain quality level, an inner jacket for long travel is therefore essential.

With or without an inner jacket – which is better?

The inner sheath is extruded under high pressure to “fill the gaps” between the cores and create our round design. This extrusion method creates guide channels within the material that help guide the cores along the cable in a controlled environment, creating more stability for continuous flex applications. Due to the nature of cables designed for motion, the cores themselves often move internally in the cable. Through these channels, we control this movement as if the cores are trains on a railroad track.

This principle is fundamentally important to both long travel and applications with small radii. Combined with high dynamics, the load on cores quickly becomes too great and the cores will break. An inner jacket ensures that the cores do not overlap and will reduce the effects of corkscrewing significantly.

Another important function of the inner jacket is that it is the foundation of the screen. It ensures that the screen strands can rest on it when moving and stays in shape. This results in a reduction in the strain on the shield wires and longer durability. High-quality EMC properties like the CF27.UL are therefore preserved for a very long time.

How do I find the right cable for high durability over a long travel distance?

In order to make the right cable selection, it helps to familiarise yourself with the following points:

- Adapt the structure of the cables to the requirements of the application

- Use service life calculator and obtain confirmed suitability

- Carry out a practical test with the first sample pieces in a real environment

If you would like to trial our cables in your application, please request your cable sample today or contact us directly for further support.