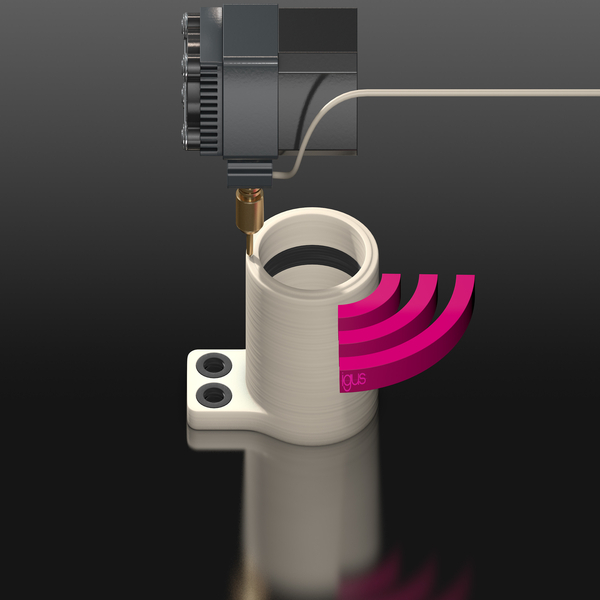

What are the main benefits of 3D Printed Grippers?

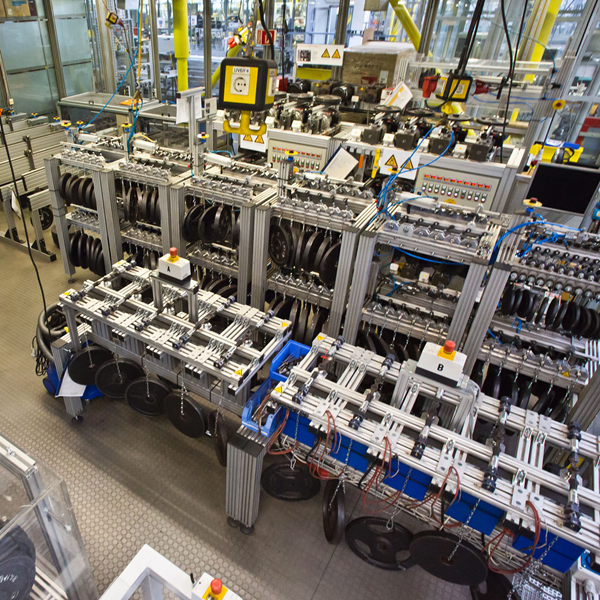

Speed and cost are primary factors of most decisions made by designers when looking at new parts. With 3d printing as an option, this reduces manufacturing time and reduces cost so it is not surprising that people are using this service for replacing metallic grippers. This blog highlights the main benefits of 3d printed grippers in comparison to traditional metal ones