The igus® digital annual press conference

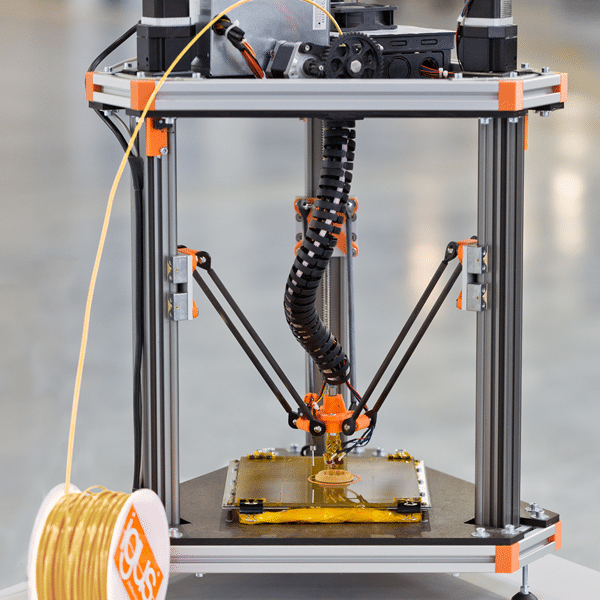

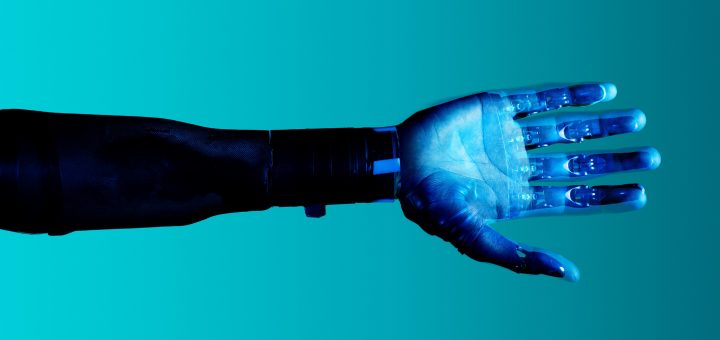

At the igus® Digital Annual Press Conference 2022, there were a range of exciting innovations from the world of motion plastics. True to the igus® motto “improve what moves”, this year we presented 175 innovations across all business areas on topics such as sustainability, digitalisation, 3D printing and low cost automation.