Single core vs multi-core motor cables for high-performance spindles

Motor cables nearly always have the same structure. Depending on the requirements, single core or multi-core motor cables are used. Both types of cables are suitable for high loads. So, what is the difference?

Why is there a different core structure?

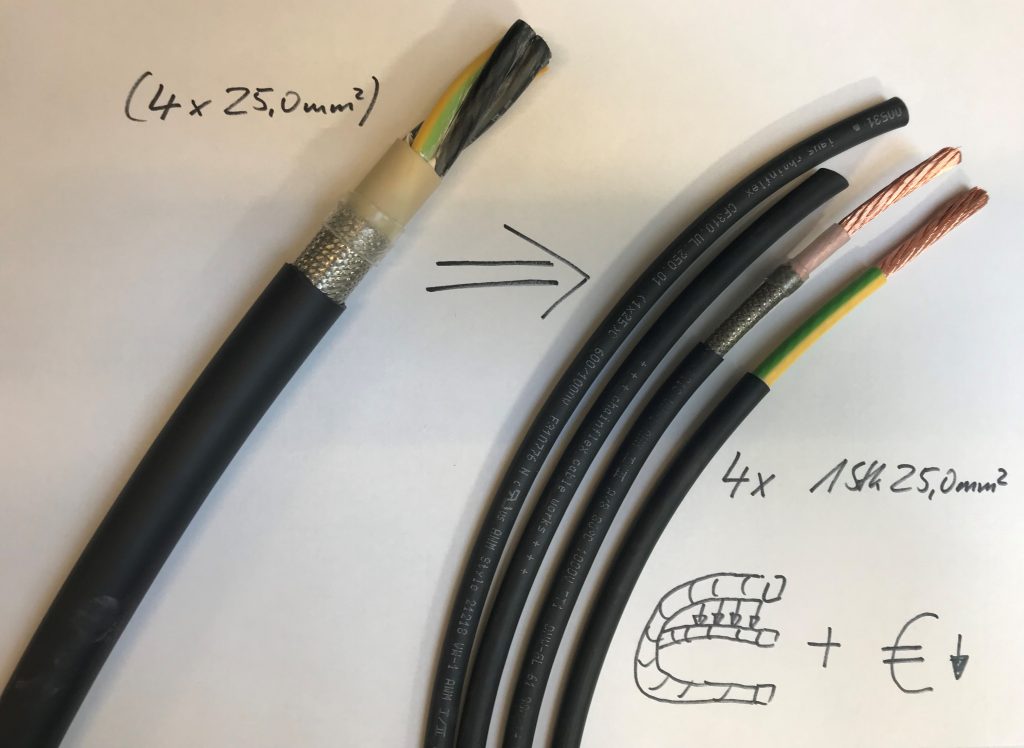

Spindle drives in processing and machine tools are becoming increasingly larger and more demanding in terms of performance and energy supply. As a result, larger cable cross sections and thicker motor cables are required. To that end, however, cables used in energy chains no longer fit into the existing installation space of a machine. The cables need to change.

Single wire versus multi-core motor cable

Cost-effective and space-saving are the two main features of a single core compared to a multi-core motor cable. Single core cables can be produced significantly cheaper than the four-core alternative. Due to the smaller diameter, faster processing speeds are achieved, which ultimately has a positive effect on production costs.

In addition to the costs, the topic of size in a small installation space can be particularly important.

Both factors make the use of single cores in energy chains on processing and machine tools particularly attractive.

The single core cable in use

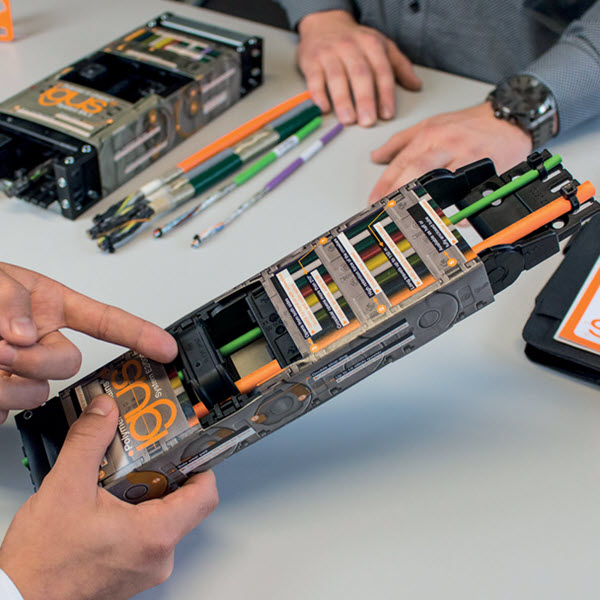

A machine tool customer recently looked for a solution for the following problem: a high-performance milling spindle mounted on the motion axis of a machine head. However, there was no space for a suitable high-end supply cable. Therefore, by using a new chainflex® spindle cable, the energy chain bend radius could be minimised by 40%, which made a huge difference to the required space.

The cables in detail

The cable used was CF310.UL.

This cable has a relatively small diameter , has permanently good EMC properties and is oil-resistant and flame-retardant thanks to a TPE outer jacket: with its UL and CSA approvals, it is ideal for machine tools.

Wherever there is little installation space for spindle cables in energy chains, the CF310.UL shows all of its advantages. Would you like to take a closer look at the line? Please read more about the product details.

The CF270.UL.D series is also a cheaper alternative with a PUR outer jacket to save installation space and cost

Would you like to save installation space, check the cables used or do you need help looking for the right cable for your application? We are happy to help you with the optimisation.

Visit the website to find out more about chainflex® cables.

Alternatively, contact the Product Manager John Barker: jbarker@igus.co.uk with any queries.