When were ball bearings first used?

Can you imagine today’s modern society without bearings? You may not realise it but nearly every kind of machine that deals with motion in its makeup, requires the use of bearings to reduce friction and to keep the motion smooth but have you considered when were ball bearings first used? Historically, when designing such machines back in the day, the choice of materials and technology was not as vast as it is today and you could certainly tell. Let’s take you back to the beginning and establish how igus® fits into the evolution of the ball bearing … It all started with wood…

When were ball bearings first used? –Introducing the bearing

If you look back at images of cavemen drawings or the way that men started to use logs to move heavy objects, this was all revolutionising the bearing. It was taking shape without anyone even realising or really investing any time into it.

Time evolved, as did the materials that were at our disposal. The introduction of base metals like zinc and bronze, which are still used today, brought the bearings into the industrial age and into an era we recognise today.

Getting creative with metal

With time came more innovation and with that came greater knowledge. Other materials began to emerge and take preference, due to their mechanical properties. The material of choice for these ball bearings migrated from wood or zinc to steel, primarily due to its strength and durability.

In 1974, Philip Vaughan was awarded a patent for his ball bearing design and subsequently, all ball bearings that followed were based on his blue print. There were adaptations to the design along the way with radical changes from the wire race changing to the groove bearing but the fundamentals remained the same.

How igus® innovated the humble ball bearing

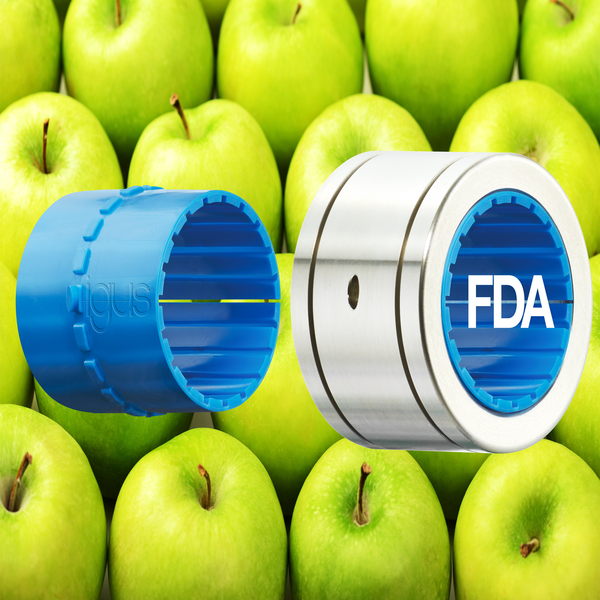

Advances in technology enabled various industries to utilise ball bearings into their applications, the automotive, machine tool and military industries to name a few. Bearings have come a long way in terms of their adaptability, their technology, their mechanical makeup and igus® knew that we could develop this and using our wealth of knowledge we created our own brand of plastic ball bearings, xiros®.

Very quickly we established that everything igus® knew about making plain bearings was not transferable to making polymer ball bearings! We had spent 30 years adapting our polymers to create low coefficient of friction and a great sliding surface, however this was the opposite of what we needed for the xiros® range, so we literally had to go back to basics. Don’t get me wrong, having the expertise in polymers meant we were able to evolve technology we already had and adapt it to suit xiros® so all was not lost!

Compared to their metal counterparts, the xiros® bearings are seen as a better alternative. They are maintenance-free, lighter, require no lubrication and have a longer service life.

We have always wanted the customer to have the power to plan, select the correct material and be able to establish the lifetime of the xiros® bearing, so in true igus® style we designed and developed the xiros® service life calculator. This helps you find the most suitable ball bearing for your application and depending on the parameters and information you add, it will give you not only a suggested bearing material it will also give you the lifetime.

We have invested a lot of time and resources into this product and recently we welcomed the addition of two new test rigs at igus® Cologne. This has tripled the size of our test laboratory for xiros® ball bearings. This massive investment has made it possible to test several factors at the same time and will help us be more precise when calculating service life. Amazingly we can now run 144 ball bearings which can be tested simultaneously at any given time and they can be tested to a maximum speed of up to 2000 revolutions per minute and a maximum load of up to 100 Newton!

Times have changed. Technology has changed. Requirements have changed but igus’® invested interest in ensuring that we are providing the best alternatives to metal bearings without compromising on their performance remains the same. Cost down, life up.

For other blogs on igus® xiros® bearings visit