Where are chainflex® cables used?

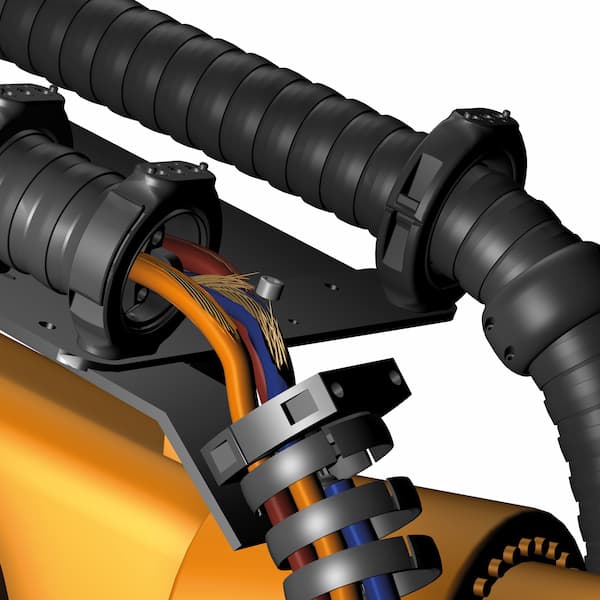

Where are chainflex® cables used? igus® chainflex® cables can be found in an endless number of industries and applications thanks to the number of environments that igus® caters for. While often used as single components, igus® cables are primarily used within energy chains and can be found in several e-chain® industries. Not only do we do a vast range of standard cables such as bus, data, control and servo, we also offer special cables for industries such as Robotic, underwater and hybrid cables.

So, how can chainflex® work for you? Below are some examples of how and where chainflex® cables are used around the world.

Where are chainflex® cables used?

chainflex® at great heights

You can spot igus® chainflex® cables across 10,000 port installations from ship-to-shore cranes, Goliath cranes, bulk handling cranes and many more. Alongside our energy chains, chainflex® cables work reliably and effectively in severe conditions. We have tried and tested this alternative to festoons and cable drums to provide a cost-effective and low-maintenance system. These work exceptionally well in these environments due to the technical properties of the cables.

For more than 10 years in a RTG crane, igus® energy systems have been working efficiently without a single component being replaced. Travelling at a speed of 70m/min the system has continuously done its job, maintenance free. These open applications mean the cables have to withstand the elements, wind, rain, snow and excessive heat.

Where are chainflex® cables used at the panto

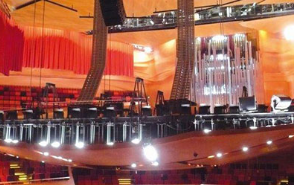

Every stage is unique and no matter what happens the show must go on. In stage construction there are many challenges, such as: high loads, noise, discretion and many more. igus® chainflex® offers dependable energy supply systems, including our highly flexible cables that can accommodate the unique specifications of every stage.

To save space, we used a zig-zag energy chain to efficiently carry our chainflex® cables in vertically suspended applications. This allows the energy system to not only be cost-effective but space-saving and inconspicuous. The cables within the energy chains need to be able to flex and retract easily without cork screwing at all. This ensures data or power remains continuous.

chainflex® in sewage plants

Sewage plants can create some of the harshest conditions for energy systems and that is why we rigorously test all of our cables. While flexibly transmitting energy, our cables can withstand stress from sun, wind, snow and ice whilst avoiding downtime and surplus costs, and still remaining maintenance-free. Whether in a longitudinal scrapper, sand, or fat trap, igus® chainflex® offers everything you need from a cable and offers customised solutions for small to large sewage plants. Ensuring that the cables can withstand extreme conditions not only avoids downtime but also ensures companies can plan for maintenance downtime. This can save thousands of pounds in downtime and labour costs.

Where we previously used a cable drum to supply energy, igus® has now replaced it with the flizz system to avoid wear to the cables. Since the chainflex® cables and the flizz system have been in use, the plant operates without downtime or maintenance fees in spite of the continuing harsh environments.

Testing testing testing

Testing is vitally important so we can ensure that the chainflex® cables are fit for purpose. igus® have the largest test laboratory worldwide and insist that every cable range is optimized and tested. This allows us to know limits, predict service lifetime and to be confident enough to offer up to 4 year guarantee on all of our chainflex® cables. For more information on how we test our chainflex® cables please visit the test page https://www.igus.co.uk/info/unharnessed-cables-tests-overview

For more blogs on our chainflex® cables please visit https://blog.igus.co.uk/category/chainflex-cables/