Flexible linear robots: where can I get one?

Flexible linear robots – sweat the robots, not your staff

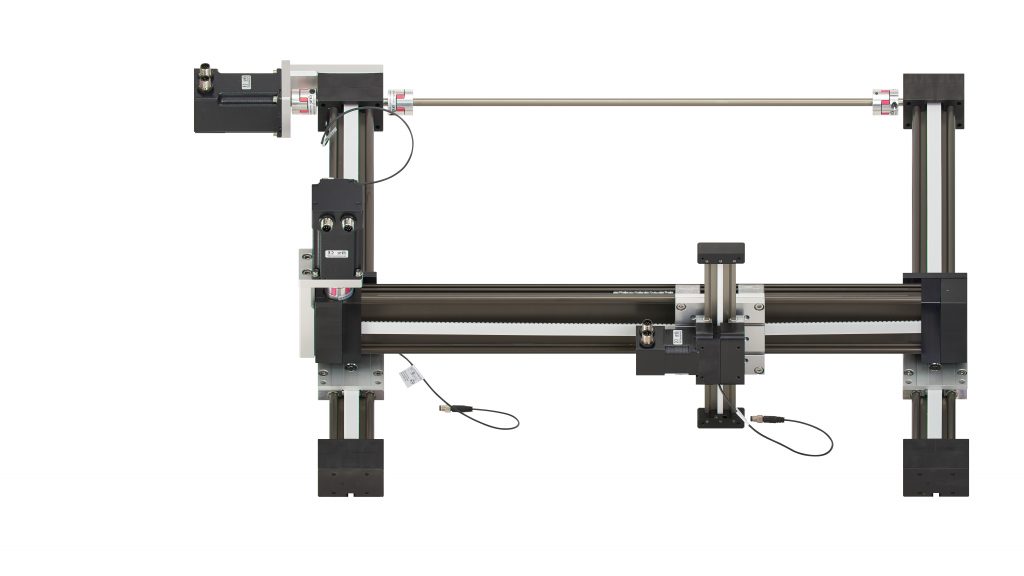

Multi-axis gantries are machinery systems that can travel across predefined surfaces or volumes. At igus®, we have gantry applications lifting hundreds of kilos for industrial tasks and others carrying out millimetres of travel for high precision tasks.

Our drylin® gantries are based on proven tribo-technology, meaning that all systems are based on gliding, self-lubricating linear units, allowing for long service life operation without any external lubrication.

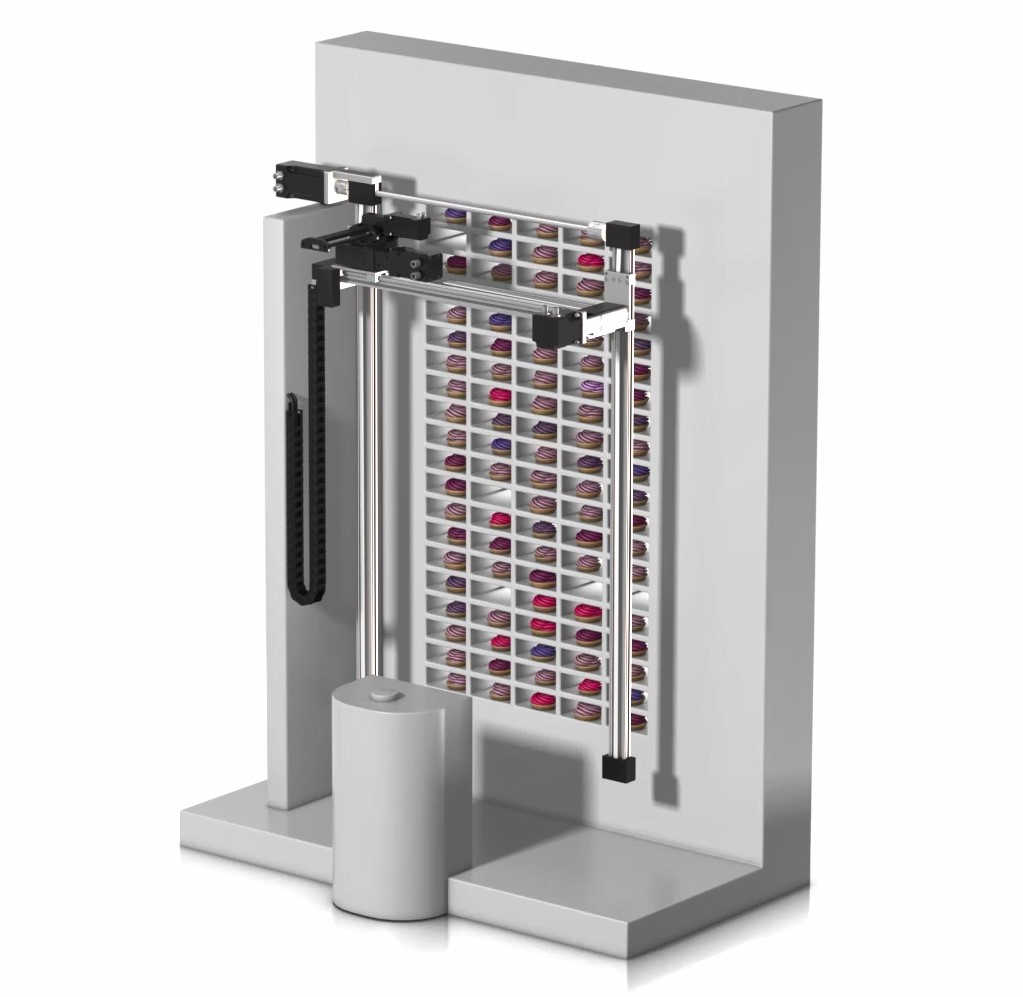

Typical applications include pick and place automation, measurement or inspection automation, assembly handling, marking and labelling machinery and handling tasks for low-cost automation applications.

Benefits of flexible linear robots

- Maintenance-free

- Dry operation

- Low noise

- Insensitive to dirt, dust and chemicals

- Corrosion resistance

- Modular design, easily modified for custom size requirements

- Standard product range available from 24 hours

- On-site consulting and design assistance

XZ: linear robot

XY: flat or surface robot

XYZ: room gantry robot

Every robot is fully customisable and can be delivered assembled or disassembled, as you prefer – modular machines mean flexible designs. Whether you are after a belt drive or a lead screw, 2 axes or numerous axes, and whatever your application requirements, we can help you find the most suitable solution from our Low Cost Automation range.

Moreover, if you require any motors, motor controllers, cables, or energy chains alongside your gantry robot, these can all be supplied by igus® too. Brand consistency and comprehensive designs are ensured by combining igus® products for your automation solutions.

Visit the website to find out more about igus® gantry robots.

Alternatively, contact our Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk for any Low Cost Automation enquiries.