Adam Sanjurgo talks dryspin®

Q & A with Adam Sanjurgo: Low Cost Automation Product Manager

Question:

Tell me about dryspin®?

Answer:

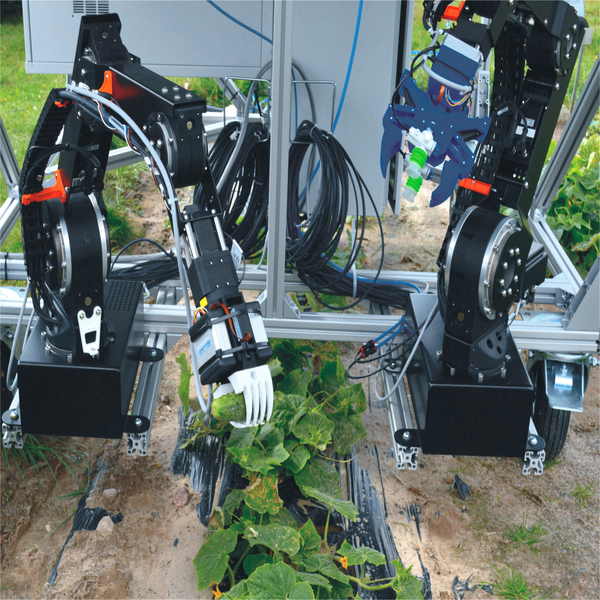

Sure, dryspin® is the range of high helix threads designed and manufactured by igus®, these are also known as steep threads or multi-start lead screws. dryspin® has been specifically engineered for optimum lifetime in fast screw applications. This product range still offers the key advantages for which igus® is well known, such as maintenance-free and lubrication-free use, predictable lifetime, ex-stock, corrosion resistance, FDA compliance with resistance to dirt, dust and other media such as chemicals.

dryspin® technology, or DST as we know it, can be combined to form a complete lead screw module that can be driven manually or by a motor.

Question:

What sort of lead screws does igus® offer?

Answer:

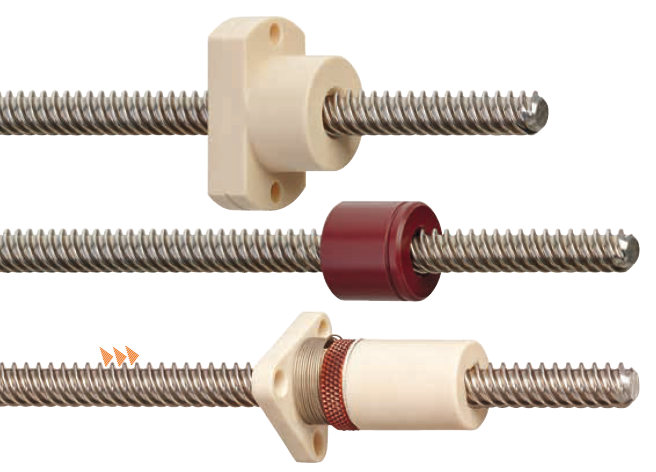

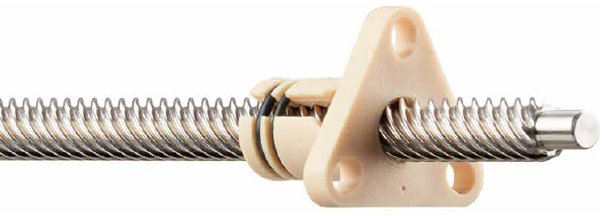

There are three main types of lead screw that we offer, which all have their place within our range. They can be defined simply as miniature, standard and fast. We have a small selection of metric threads which we class as our “miniature” range, the sizes offered in this range are M3, M4, M5 and M6. These are typically combined with our miniature lead screw module system: SLN.

Our “standard” range comprises of a huge collection of trapezoidal threads, with sizes from TR8x1.5 to TR50x8 as standard, and we can go as large as TR70x10 in special instances. The “fast” range is our dryspin® range, which is specially designed for fast applications – featuring thread sizes from DS4x2.4 to DS20x90. More information on all types of thread can be found on the igus® website. Alternatively, please contact us with your requirement and we’ll give it our full attention.

Question:

How are these lead screws powered?

Answer:

This will depend entirely on the customer’s application. Typically, a lead screw will be driven manually by hand or by way of a motor. The customer’s unique requirement will determine which way the lead screw is powered. For example, on a packaging machine, there may be infrequent format adjustments depending on the product running through the machine on a day to day basis.

Infrequent movements are typically done manually, simply for cost reasons. More repetitive motions such as product transfer mechanisms, which may have many cycles per minute, would typically then need to be motorised as they will be part of a process that the machine is carrying out. igus® offers both options.

Question:

What are the main benefits of igus® lead screws?

Answer:

As with all igus® products, we have a vast range of benefits compared to conventional solutions. Thanks to the use of tribologically-optimised polymers, we can offer many industries and applications some serious benefits, such as maintenance-free and lubrication-free systems, cost-effective solutions, a high resistance to dirt dust and other media, corrosion resistance, FDA-compliant materials, predictable lifetime and deliveries from stock in the UK, to name just a few of the benefits of igus® products.

In the range, we have various standard nut materials that complement different applications with different environments. We also have a vast range of stock bar materials, from which we are also able to machine standard or bespoke designs.

Question:

How can these advantages be demonstrated?

Answer:

Good question, and a question that I wish more customers actually asked igus®. At igus® GmbH [igus® headquarters in Germany], we have the largest test lab in our industry, with 3,800 square metres filled with all manner of testing equipment. In this lab, we conduct over 15,000 tests each year.

These tests are conducted to give accurate data on the lifetime of the products we offer. This data is then directly filtered into our many product expert systems, to give the customer the ability to directly calculate the lifetime of an igus® product in their application.

For dryspin®, we have our expert system section on the website where you’ll find the “expert system for lead screw systems”. Here you will find a comprehensive tool where all application information can be loaded into the expert system to give an accurate lifetime for the application, which can be filtered through accordingly.

Question:

Do dryspin® products come as standard or can a customer order them bespoke for their applications?

Answer:

Flexibility is key here and, as with all igus® products, not just dryspin®, we strive to deliver the best and most complete solution or product to the customer. When I say complete, I mean that if the customer has machining work required on the lead screw, then we offer them these services too. This covers all three types of thread that we offer. By doing this we not only reduce logistics but also administrative time for the customer.

We offer a free configuration tool found here: “lead screw configurator” where you’re able to configure a completely bespoke lead screw to your requirements and receive a price, CAD file and PDF drawing generated at the end. We also have a how-to guide on our blog.

You will find, by using the tool, that incredibly complex designs can be generated in a matter of minutes, saving hours of design and drawing time. See below an example of what can be generated in an incredibly short time.

Question:

Does igus® offer accessories and extras with dryspin®?

Answer:

Absolutely, as I’ve said previously flexibility is key here and the most important thing is to provide the customer with a solution that not only fulfils their application requirements but also saves them time and money in the process. This is done with some of the accessories we offer with our range of threads including dryspin®. Accessories such as lead screw support housings, lead screw nut housings, and clamping rings to assist the customer to locate the lead screw in their machine properly, are just some of the accessories we can offer.

When discussing such requirements with the customer, the talk can quickly develop into more of a built-up system including our drylin® rail systems.

Question:

How can a customer find out more about dryspin®?

Answer:

In any way that the customer feels most comfortable. We have many ways in which we can assist with an application or simply showcase the products if the customer wants more information – this could be face-to-face, virtually or over the phone. We have a team of engineers covering the UK and Ireland waiting to assist with the application and give guidance on which dryspin® lead screw is the best for the customer’s application.

We also have various digital platforms that the customer can use to find more information on dryspin®, these could be with the aforementioned tools such as our expert system, or lead screw configurator, it could be information found on our blog site such as how-to videos and other relevant articles. For me, there is nothing like the personal touch, so if you need assistance with anything related to lead screws please give me a call.

Question:

What about using dryspin® in combination with a motor, how do we connect them?

Answer:

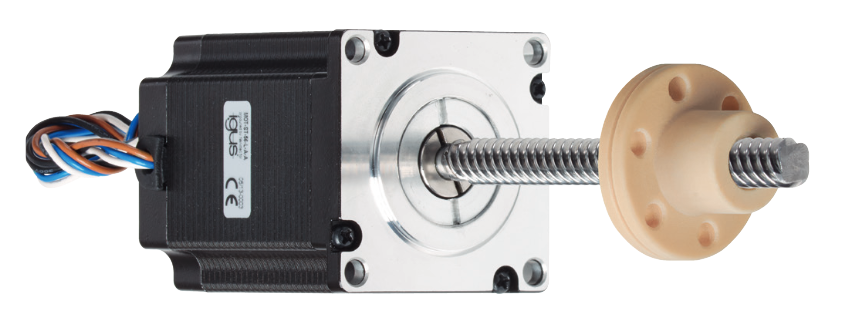

A very good question, and one that always comes up when discussing motorised applications with screws. Customers will ask how this connection between motor and lead screw can be done as efficiently as possible. Well, igus® has the perfect solution in the form of our range of spindle motors or lead screw motors. This is a motor that is designed to mechanically fix directly to the lead screw itself. Removing the need for such connection parts like couplings or clamping mechanisms. We have these motors in three different NEMA sizes, NEMA11, NEMA17 and NEMA23, we offer the motor with or without encoder and we fully assemble the screw to the customers desired length and deliver as a finished product that they simply bolt into their design. One order, one part.

Visit the website for more information about our Low Cost Automation range.

Alternatively, contact the Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk with any enquiries.