How can robots help humans?

How can robots help humans?

Today, it is evident that robots have a mixed reputation due to societal rumours and real issues faced by workers; however, there are enormous sectors and businesses that could not function without the use of robots and automation systems. Their precision, strength, and ongoing energy levels make them ideal employees for the practical and theoretical tasks that humans find difficult or boring to do.

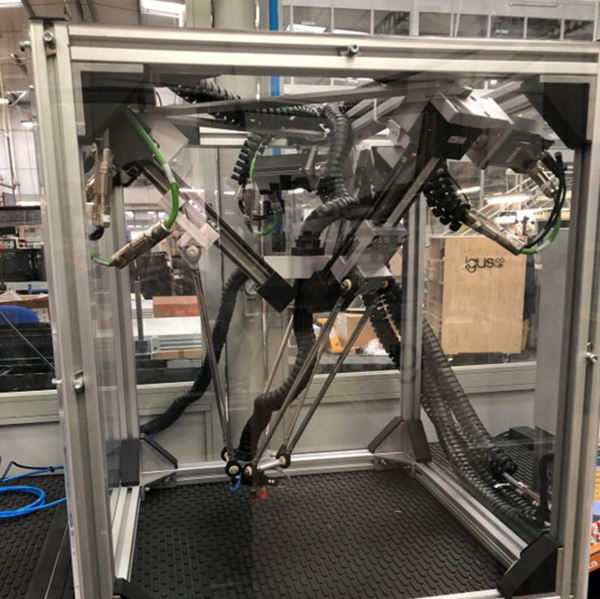

It is widely known that robots represent a crucial part of the automotive industry. Here, high-powered robotic arms are used with different tool attachments for assembly line tasks such as gluing and placing windscreens, or carefully lowering engines into cars. The importance of robots in vehicle production is to eliminate risks to humans such as fatigue and injuries when performing wide-ranging tasks such as welding, painting, and installation. By improving productivity, efficiency increases within this multibillion-pound industry on which many countries heavily depend.

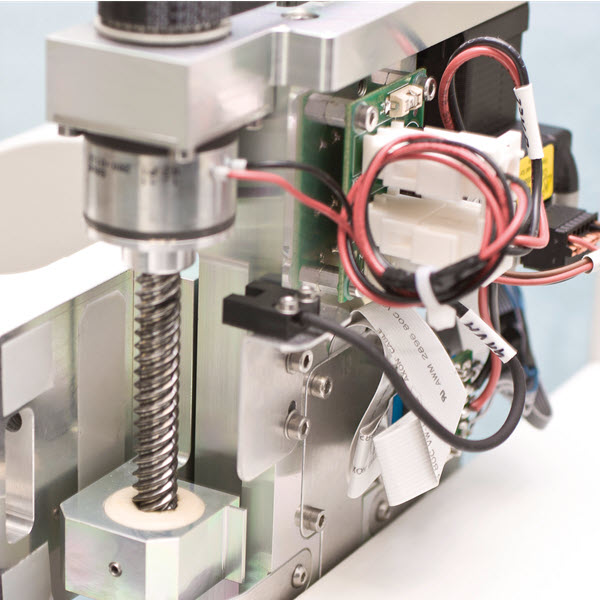

igus® robots are used in automotive factories for high speed tasks requiring low coefficient of friction to ensure smooth and vibration-free motions.

Other sectors using robots to achieve results and advance in their industries are in space and underwater exploration. These two fields depend upon robots to carry out dangerous tasks that pose risks to life, if carried out by humans. This enables us to uncover more information about the deep seas and outer space, while staying safe and not risking unnecessary interruptions of our natural surroundings.

igus® robots are used in underwater investigations, where other robots would be subject to corrosion and rusting while in such wet environments.

How can robots help humans? Safety with robots

In terms of features, robots certainly produce high standards when it comes to safety and reliability.

With regard to safety, robots are made out of materials that are approved by governing bodies for each industry, such as: fire retardant properties in clothing, food-safe materials on food production lines, and drug-safe materials in pharmaceutical production. Similarly, robots are required to be fitted with safety features to ensure: an emergency stop when required, stalling when excessive forces make an impact, and shutdown if safety zones are entered.

igus® robots can all be fitted with these safety features and are therefore accepted in all sectors from food and beverage to industrial manufacturing.

In addition, robots are functionally more efficient in many tasks than a human counterpart. In this way, robots can be taught skills specific tasks and redeveloped for new ones, with very little preparatory training and subsequent guidance. This reduces downtime when new jobs are introduced to staff, as well as when teething issues arise after implementation. Therefore, robots are most reliable for the changeable environment of production in the multiple industries that require factories for their success.

Furthermore, while changing the roles of robots, one can also monitor and test them during the working day. Not only is this useful for the analysis and upkeep of machinery but also for the observation of targets and KPIs. Humans are brilliantly creative, and each one unique, but also sensitive to environmental and psychological changes which can prove damaging to a hands-on workforce.

igus® robots are all modular and are made up of stocked components which makes them very flexible for internal production changes.

At igus®, we recognise that speed, safety and flexibility are key factors of a successful business, our products reflect this to keep our customers rest assured that current and future jobs can be achieved.

A final, significant aspect of robots is that they are now available as low-cost investments, which schools, colleges and universities can afford. It is essential that companies, where possible, engage with young minds and engineers of the future at the grassroots level, to equip and prepare them to face the industry issues upon finishing their somewhat less-practical studies.

So, how can robots help humans? Automation is the future and working collaboratively is the future.

igus® is proud to provide low cost automation products to educational establishments for educating and training their students while studying the syllabus. In addition, igus® offers a special Young Engineers Support (YES) programme to encourage students and mentors to use freely-donated igus® products for the benefit of their studies and research projects. Additionally, we offer visits to our factory in Northampton, guest lectures, and internships at igus®.

For more low cost automotive blogs visit the blogs main LCA page or contact the Low Cost Automation Product Manager, Adam Sanjurgo: asanjurgo@igus.co.uk for any robotic enquiries.