3 advantages of plastic components in car interiors

The car industry is notoriously difficult to satisfy, especially with such high standards in every area of production. With the development of intelligent driving and electric vehicle technology, more electrokinetic products are being installed within car interiors. A prime example of this is on pivoting seats, with long travel, retractable displays and smart glass applications.

The key elements for automotive is security and comfort to increase the driving experience, whilst maintaining a level of costs that is feasible for both the manufacturer and the customer.

With the implementation of more kinematic features into the car interiors, the requests for weight reduction, noise-reduction and inevitably a reduced cost becomes more of a challenge. However, not so much for us. In fact we thrive on the challenges that arise from the automotive industry.

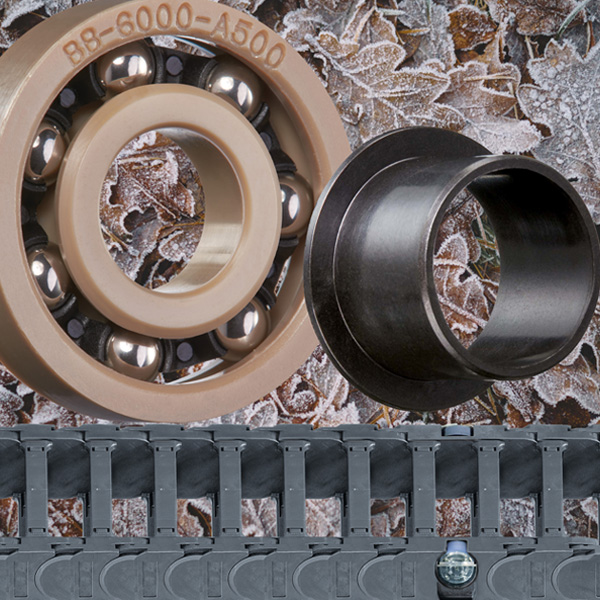

With special iglidur® materials for bearing solutions and the unique design for dynamic cable protection e-chains® they are able to establish operating noise levels at less than 40dB. Not only is the reduction in noise possible using igus® products but this can be achieved at a lower cost than metal alternatives.

Here are some key features for reducing noise, weight and cost within car interiors:

Reduce costs

Pricing pressure is not uncommon in this industry and it is forcing designers and OEMs to look at alternatives to traditional parts and methods to ensure they are continually optimising their costs.

Today, almost every motor vehicle that is made contains polymer bearings as a substitute for metal plain bearings or rolling bearings. The uses of these polymer bearings range vastly from seat systems to high temperature applications in the engine compartment, in shift forks for gearboxes to coolant pumps. It is easy to see why these alternatives are replacing traditional materials.

- Less energy required in the manufacturing process

- A lot less crude oil is required to make the same volume of plastic compared to that of steel; 11,000 litres to make 1m³ of steel; for 1m³ of plastic, only 1,000 litres.

- 7 times lighter than the metal equivalent

Reduce weight

The landscape is continuously evolving in relation to the reduction of vehicle emissions and predominately the main way of achieving this is through reducing the vehicle weight. This is also beneficial in regard to the fuel consumption: less weight leads to less fuel consumption, whether this is electric or liquid fuel.

An igus® iglidur® polymer bearing is up to 80% lighter than a conventional metal bearing and this is without compromising on the output of the part. But do all polymer parts weigh the same no matter which material they are produced in?

The answer to that is no. igus® offers a large range of materials that are suitable for automotive interiors, all of which weigh differently, are capable of different temperature ranges and have varying chemical resistant properties. igus® bearings weigh less than metal bearings and therefore contribute towards the reduction of carbon dioxide emissions. Another advantage of igus® polymer bearings is that they do not require any additional lubrication, which, ensures they are clean and environmentally friendly.

Reduce noise

The expectations of the manufacturers within this industry is continual. Noises always arise where components interact with each other and cause friction or ‘rattling’, especially within car interiors. With the tribologically optimised high-performance polymers from igus®, you achieve a quiet application through low coefficient of friction. This is also helped by the selection of dampening materials they offer, reducing the vibrations therefore reducing noise. Plastic materials are vastly superior compared to metallic components when reduction of noise is the focus.

The variety of applications for igus® iglidur® plain bearings inside vehicles is vast, ranging from vehicle seats, hinges to actuators, steering systems, cooling fans and aerodynamic adjustment.

If you need help reducing weight, noise or cost in your application, check out the website www.igus.co.uk or ring and speak to one of the igus® experts. For more blogs on the automotive industry click here