Why do you need FDA approval?

FDA approval is crucial for all food and packaging sectors, as well as those that create parts for these industries. Before being on the market, not all products require FDA approval. However, in the case of safety, the FDA has regulatory jurisdiction over the majority of them. At igus® we ensure FDA approval across a wide range of products to ensure those industries with such criteria can benefit from igus® parts.

FDA approval in igus® products

At igus®, we ensure FDA approval across many of our products and materials for a variety of applications. These range from packaging raw food in factories to dispensing liquids with an FDA approved robot. FDA approval ensures products will boost efficiency and cleanliness in a food and beverage production line

Our materials are all tested to a high degree to ensure safe and hygienic properties, while staying long-lasting and resistant to necessary wash down procedures found in the food and beverage industry.

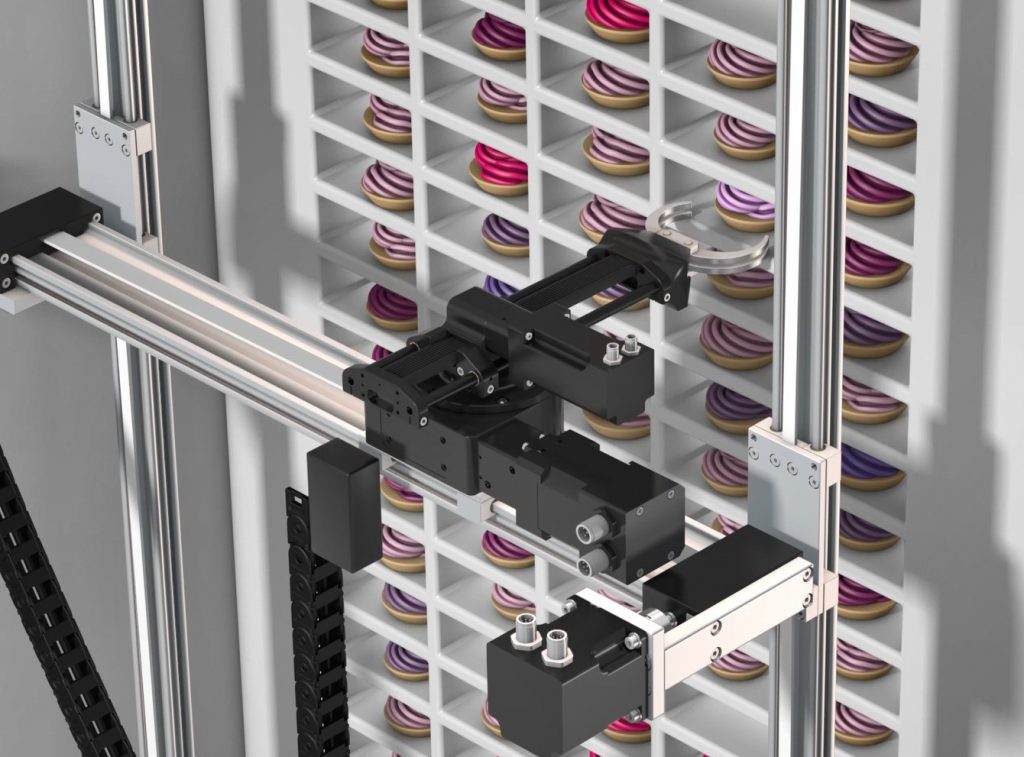

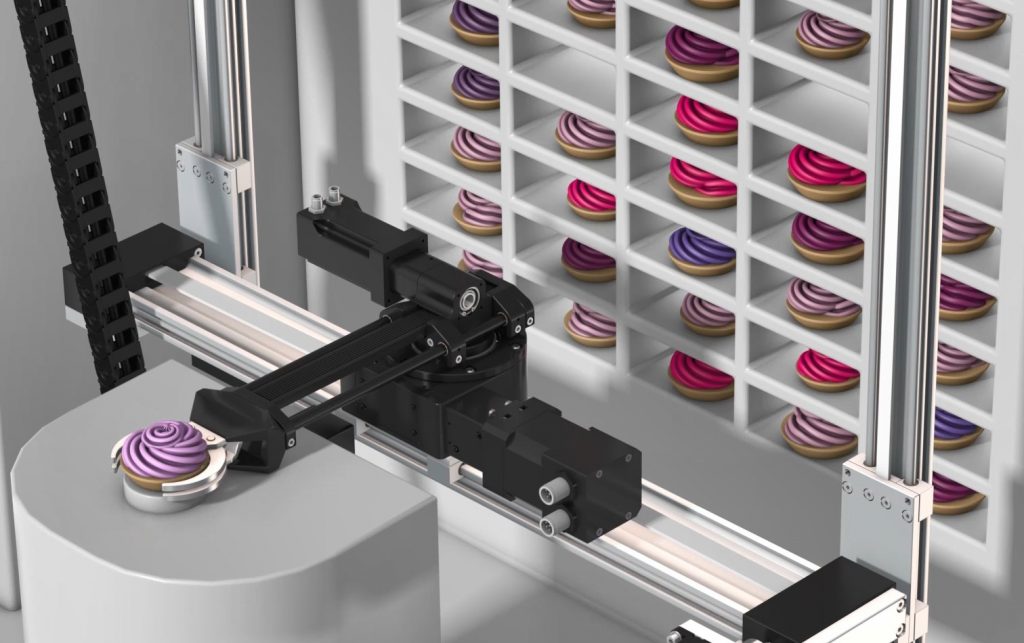

To the right, we can see igus® gantries operating in a food and beverage application with baked goods. Pick and place tasks are very common in the food and beverage industry, and igus® hence produces numerous standard and bespoke solutions like this one within its Low Cost Automation range.

To read more on the topic of FDA approval at igus® click here

Food-safe solutions with igus®

3D Print® solutions

With many igus® 3D Print materials already available, and the 3D Print market growing year-on-year, igus® released an FDA-compliant material for FDM printer users. Our I150-PF is the food-compliant filament that possesses not only the beneficial properties that are typical of igus® products, but also unique tribological characteristics that make it a preferred option for the food and beverage industry. This filament is compliant for raw food tasks: compliant with EU Regulation 10/2011, the easiest filament to process, has high resistance to abrasion when working at low surface speeds, and good mechanical coefficient. It’s also surprisingly cost-effective!

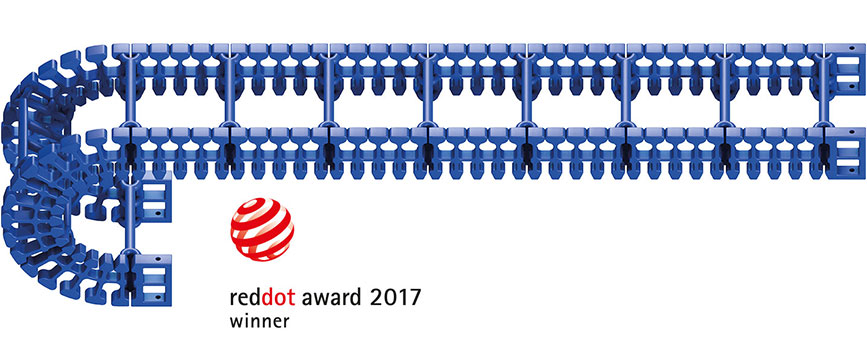

Energy chain solutions

The hygienic e-chain® represents the world’s first ever plastic e-chain® that complies with the “Hygienic Guidelines”. This e-chain® features the typical favourable properties of igus®: no material-on-material wear, long-lasting polymer design, high bend radius, maintenance-free polymers. Other characteristics are also boasted by this food-compliant product: it has no bolted connections, operates between -40°C and +70°C, rounded edges to ensure no dead spaces thus keeping dirt and germs away, and wide gaps to ensure easy wash down with both water and aggressive chemicals.

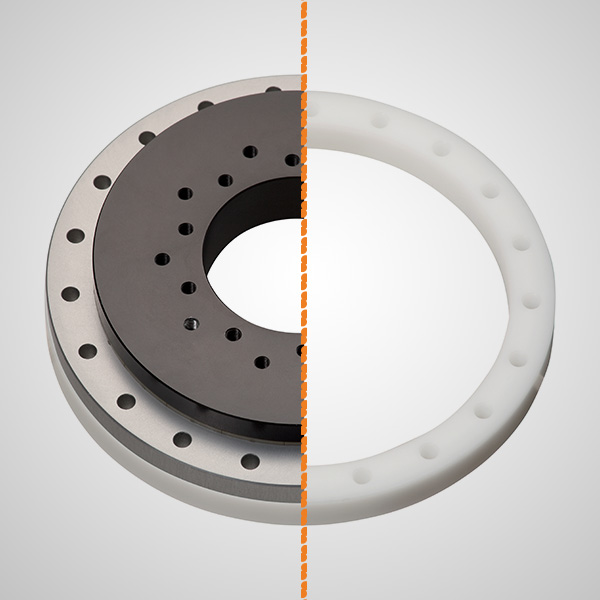

dry-tech®: drylin®, xiros®, iglidur®, igubal® solutions

Our FDA-compliant dry-tech® products can be used alongside raw materials such as meat, vegetables and baked goods. Thanks to their lubrication-free properties, igus® bearings and rails can work without the trouble of selecting allergen-free oils to lubricate machines. The other benefit from using our FDA-compliant materials, is that they are versatile for a variety of applications, whether needing low or high temperatures or high speeds for the production line.

Low Cost Automation solutions

As in the above examples, the igus® FDA-compliance stretches across multiple components. However, while most product groups incorporate their own components, the LCA range uses parts from almost every product group. For example, on a belt-driven gantry, there are linear bearings supporting the motion of the rails and carriages. As well as this, there are ball bearings with polymer cages located in the end blocks for faster and more accurate movements. These polymers can be replaced with our FDA-compliant polymers to ensure absolute adherence to the industry regulations.

The rails are usually supplied in hard anodised aluminium but can be further customised in stainless steel for wash-down applicability. As we can see, igus® truly pulls out all the stops when it comes to approved materials and components for all industries, the food and beverage industry being no exception. Whether your business is involved in making and servicing machines, designing robots or constructing entire production lines for handling food, look no further than the igus® food industry range!

Visit the website to find out more about the igus® food-approved materials and components that we produce.