Industrial Robot Maintenance: What you need to know.

In industrial manufacturing, robots are becoming increasingly useful, working to ensure efficiency, precision and relieve workers of low-skill tasks. As with any piece of machinery, they require regular maintenance to keep them running smoothly. Here’s what you need to know about maintenance of industrial robots.

Regular maintenance

Regular maintenance is crucial for the longevity and performance of industrial robots. Without it, you risk unexpected downtime, costly repairs, and a decrease in productivity. Servicing your car prevents you from running into issues later down the line that could be more costly and this exact logic applies to industrial robot maintenance! By implementing a proactive maintenance schedule, you can ensure that your robots remain in optimal condition, reducing the likelihood of unexpected failures.

Key maintenance practices for your robots

Routine inspections: Regularly inspect your robots for any signs of wear and tear and look for loose connections, worn-out parts, and any unusual noises that could indicate a problem. In moving applications such as these, preventing cable failure is a top priority. The triflex ® R is a 3D cable management system for robots that also enables rotation of around 10 degrees per chain link. Being able to guide robot cables safely helps to remove the threat of cable failure and allows your robot to function freely. Not only this, if you choose to use igus® robot cables they these come with a 4-year guarantee so your machines can run uninterrupted.

Lubrication: Proper lubrication is essential to reduce friction and wear on moving parts. igus® do things differently when it comes to lubrication, using motion plastics that are self-lubricating and maintenance-free. From bearings to linear drives, energy chains and low-cost automation, igus® are encouraging the switch to GOZERO Lubrication to save customers time and money lubricating their machines while reducing the impact we have on the environment.

Find out everything igus® are working on to be sustainable.

Cleaning: Tidy space, tidy mind. Keep your robots clean to prevent dust and debris from interfering with their operation and save the hassle of repairs. Use appropriate cleaning agents and methods to avoid damaging sensitive components.

Software Updates: Just like any other technology, industrial robots benefit from regular software updates. These updates can improve performance, fix bugs, and add new features.

Calibration: Regular calibration ensures that your robots are operating with the highest precision, particularly important for tasks that require high accuracy and high-quality end products.

Predictive Maintenance

Predictive maintenance is a game-changer in the world of industrial robotics. By using sensors and advanced analytics, you can predict when a component is likely to fail and address the issue before it leads to downtime. This approach not only saves time and money but also extends the lifespan of your robots.

igus® understood the importance of predictive maintenance and created i.Cee. Our very own predictive maintenance system, i.Cee is igus® software combined with sensors used on energy chains, plain bearings or linear slides that helps you to monitor the service life of your product.

Training and Documentation

Ensure that your maintenance team is well-trained and familiar with the specific requirements of your robots. Comprehensive documentation and maintenance logs are also invaluable resources that can help troubleshoot issues and track the history of each robot.

Maintaining industrial robots is not just about preventing failures; it’s about optimising performance and ensuring that your production line runs smoothly, so regular checks keep your operations on top form. By following maintenance practices like these, you can maximise the efficiency and lifespan of your robots and be on top form in your industry.

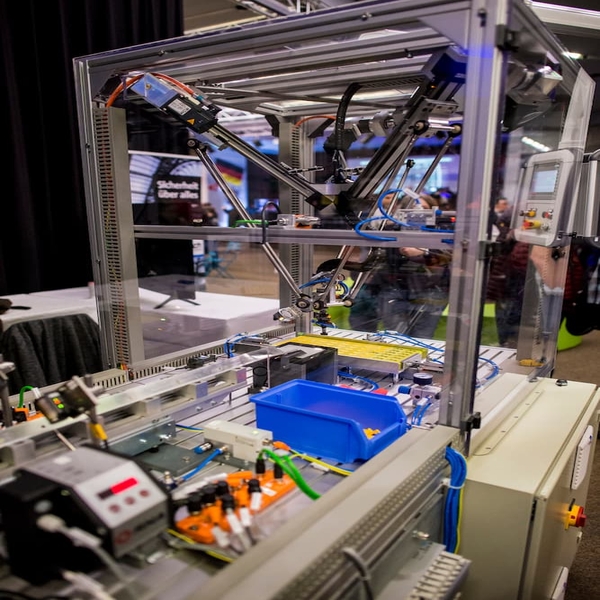

Low-cost automation

igus® can support the switch to lubrication-free solutions with a range of products to suit every industry. The RBTX marketplace hosts automation components from various leading manufacturers with a configurator and compatibility guarantee and helps new and experienced customers find the perfect solution for their businesses.

Often, a barrier to entry for many SME’s looking to automate is steep pricing. That’s why igus® created the RBTX marketplace to provide low-cost options that makes automation more accessible.

Become an automation expert with our other resources here.