Investing big in crisp manufacturers

The UK’s food and drink industry is the country’s biggest manufacturing sector by turnover, valued at £104.4 billion (Food and drink – great.gov.uk international). This presents many opportunities for manufacturers like igus® to provide solutions that will help these businesses package, process and distribute food efficiently.

Crisps are a staple snack in the UK, with an estimated 6 billion packets consumed annually. The first commercially sold crisps were produced in the UK in 1853 so this is an industry with a wealth of experience in mass production.

Why invest in crisp manufacturers?

There is no shortage of crisp lovers in the UK and the revenue of the entire food market in the UK is estimated to be just over £151 billion as of 2023 (Food industry in the UK – statistics & facts | Statista ) Despite being such a well-established industry, the top companies are constantly looking to improve as consumer preferences are moving towards more premium brands, sparking a race to innovate amongst the top performers in the industry.

Investment in new technologies can lead to significant enhancements in efficiency and sustainability, reducing waste and energy use while increasing output. Companies that prioritize these investments are better positioned in a changing market.

This way they can quickly adapt to consumer trends, ensuring their products remain relevant and desired. Embracing innovation, therefore, becomes the perfect way to secure a competitive edge in a market where consumer preferences are always evolving.

Piper’s crisps investment plan

PepsiCo, which own Piper’s crisps are investing £8 million into their manufacturing site in Lincolnshire, coinciding with the brand’s 20th anniversary. The BBC reports here that the goal seems to be to boost production capacity at the site by nearly 80%, replacing existing crisp fryers with energy efficient models and installing new packaging machines.

Having sold £89 million worth of crisps in 2023 (twice as much as their previous year), it’s clear that production is rapidly increasing so investment is much needed to continue to be successful.

Not only are they looking to increase production, but the investment will also go towards upgrading facilities for employees. Providing improved spaces for employees is essential to having a workforce that feel valued and included in the business’ plans to expand and improve efficiency.

igus® can help

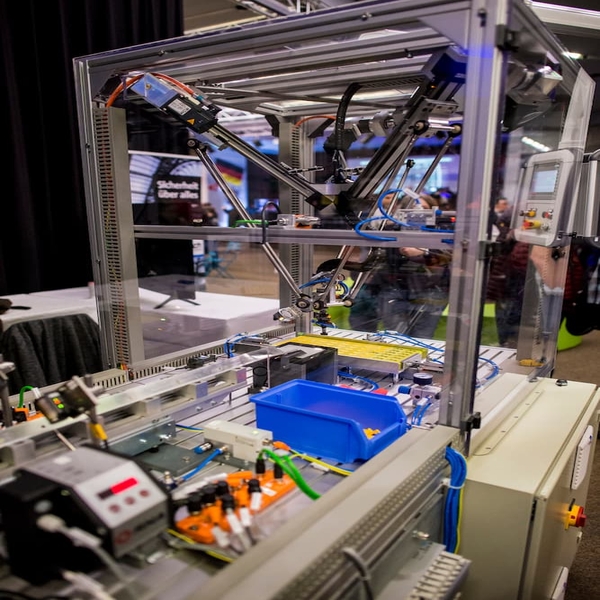

We have supported a variety of different industries with their plans to upgrade their production and automation. Many customers seek out ways to boost efficiency and with our expertise in high-performance polymers we can offer lightweight and durable solutions.

The crisp manufacturing industry is no exception, with igus® lubrication-free and low-abrasion components used on hygienically sensitive production lines, making igus® both the sustainable and cost-effective choice for your applications.

We offer food compliant products such as self-aligning bearings and hygienic energy chains in the signature blue colour used in the food industry designed to be easy to clean and tolerant of high temperatures. We are keen to make our products work for you, so if you have specific requirements and would like special bearing parts, we can produce these for you too!

Learn more about our igus® range of FDA and EU compliant products.

The future of crisp manufacturing in the UK

Firms that are proactive in implementing new technologies and sustainable production methods are setting themselves up for success. Investments, similar to PepsiCo’s commitment to Piper’s Crisps, demonstrate the sector’s potential for growth and the importance of adapting to consumer trends.