Looking inside igus®

Q & A with Matthew Aldridge: Managing Director of igus®

Question:

Tell me how igus® is helping industries of today

Answer:

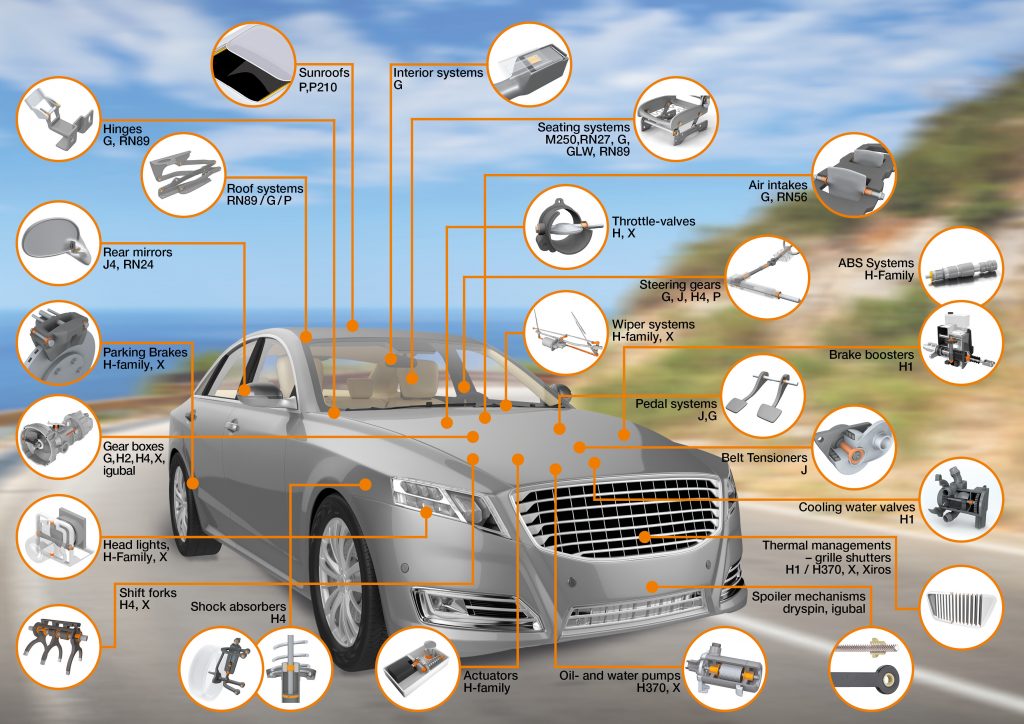

For the industries of today, although technology has developed considerably over the last decade or so, the issues that are being faced are timeless. Customers are trying to take cost out of their machines – to make their business more profitable and to give them a better position in the market – and improve the technology. If you think of the car that you’re driving, in real terms it’s possibly even cheaper than the car you were driving ten years ago, certainly roughly the same price and yet the technology that’s in that car is much greater than it was a decade ago. We’re helping with that as we are always developing new products which save our customers money – and I will come onto how we do that in a moment – and also products that improve the life and technical performance of machines. We are always pushing that envelope.

But it’s not just about saving the component cost, we try and do that as well, but it could be saving time – and time is money, so we come up with new products which can be used in ways that are very lean and would lend themselves to easier manufacturing processes. That helps deliver this whole package of saving money and increasing performance with our customers. So, an igus® product should always do at least one of two things: it should save money, either in real cost or time; and it should improve the technology. It should do one of those two things, hopefully, both, if it doesn’t do either then it’s not an igus® product.

Question:

In terms of technology, what sort of products does igus® bring to the market?

Answer:

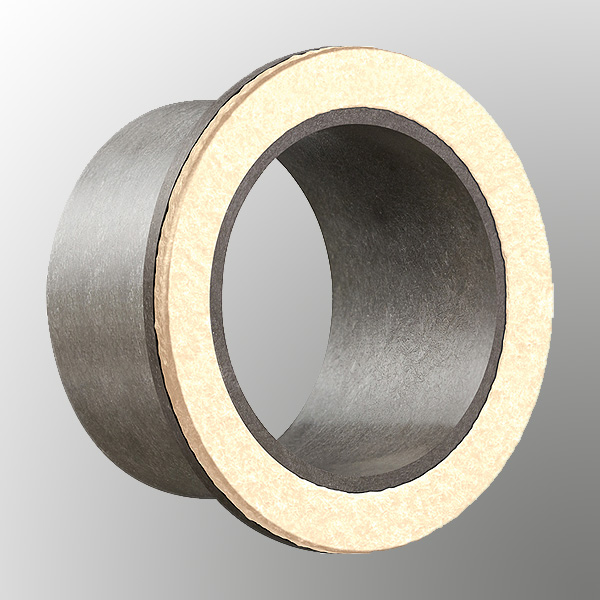

We are often compounding new materials. We are a plastics company, so we are looking at what new materials are available in the market, and also blending our own to further optimise materials to give greater performance and also to match market trends. With the automotive industry as an example, the current trend is to use non-ferrous-based metals such as aluminium and perhaps even carbon fibre as a sliding surface, as a shaft. Traditional bearings and even the older igus® materials wouldn’t run particularly well against those sliding surfaces, so we have developing materials that will run against those materials which are now being used in that industry. This versatility helps that particular sector to move forward in the direction that they want to go.

But that it looking just at the component level, we are also looking at the system level, taking a more holistic approach to new technology, and that’s where our smart plastics come in.

Question:

Could you tell me more about igus® smart plastics?

Answer:

We have intelligent systems which are built into our products that allow for live performance monitoring, wear rate detection, failure mode analysis, etc. All of this is happening live, and we can do complete systems which are already being implemented by many customers where these are running in our chains, cables and bearing systems across the world.

Question:

A big and emerging sector is robotics and automation. What is igus® bringing to that field?

Answer:

You’re right. There’s huge pressure on companies to automate and that’s being driven by the need to compete on a global level. We have rising wages, of which I am in favour, the living wage is going up every year and that means that customers would need to automate. You cannot just have rows of people doing repetitive jobs – you need rows of robots doing repetitive jobs and you have to upskill those existing workers to work in the automation industry.

Just as aside here: often people are worried about robotics and automation taking away jobs, and on the face of it that is a rational fear, but when we look at recent history over the last 50 years or so, that has never happened. Automation has always led to an increase in jobs and a decrease in unemployment. So, that’s just a bit of reassurance for anybody that would have any of those misgivings about this.

Question:

What is igus® producing?

Answer:

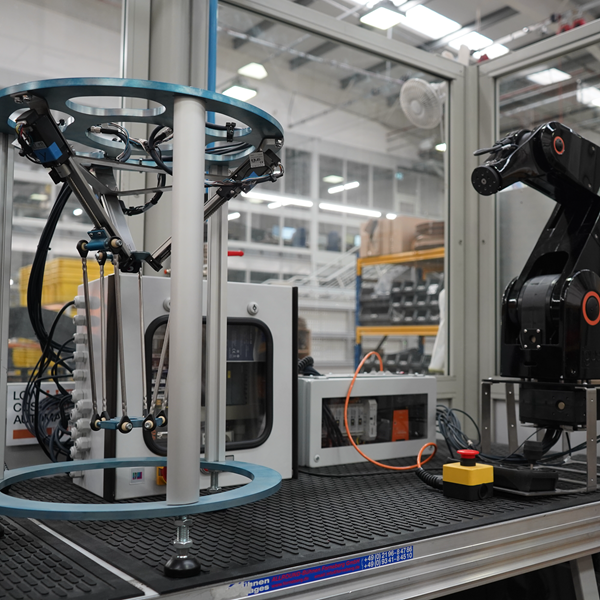

Well, here we see a space for low-cost automation in the market, and that the robotics companies tend to be focused on going bigger, faster, better and they’re ignoring this space in the market where people want to get into robotics. These companies haven’t got hundreds of thousands to invest but they do want to move this way and they don’t mind spending £5,000 or £10,000 on a low-cost robot to do a very simple task. That is the space that we are in, to deliver either sub-assemblies or indeed fully working robots which are in that low-cost automation space. You can get, from igus®, a fully-functional delta robot for £5000. No one else is near that.

Question:

How do you do that?

Answer:

Well, it’s not that other companies are ripping people off, that’s not the point at all. We do it by taking igus® standard parts and assembling those parts to make a robot. So, by using existing standard parts, we have already got the economy of scale. We’ve already managed to drive all of the cost out of these components and we’re then passing all of that saving on to our customers – and they benefit from that.

Question:

Can you tell me how igus® opens its doors to innovation?

Answer:

Yes, I can. Ah, perhaps I should have answered that: yes, we can. We have a philosophy which is taught to everyone that is customer-facing at igus® which is that a response to a product request should always be: ‘yes, we can’. Now, it may not be that we can do it right now but yes, we want to. We want to be able to offer this product that meets the customer’s requirements. Our salesforce is taught this, and our salespeople are taught to listen to what the customers are asking for, what trends are in the marketplace and then to feed that back to the product managers. This drives our new product development.

To give you an example of that, we were given the challenge by one of our large customers to only provide them with components that hold UL 94 fireproof rating. The products at the time did not have that grade, we had a small range of products that had this rating but certainly could not cover all of the customer’s requirements at that point. So, that was fed back and we said to the customer: look, give us 6 months and we will come up with something. They agreed to work with us and after a lot of consultation along that journey, this project led to a complete product range and that customer is now buying all of these parts from igus®. That has opened up a market for us as well because we can now approach other people in that sector, and even other sectors, who need that certification to offer our products to them.

So, the point is that it’s all customer-driven – we launch hundreds of new products every year. Now, we don’t have a load of scientists in white coats sitting in a lab in our manufacturing base just scratching their heads trying to think of new ideas, that’s not the way we work. We are listening to customers and getting the ideas and demands from our customers and then these guys in white coats are delivering on that. This means that when we launch a new product, we know that there is at least one customer that will want it; normally many others. These lead to some really strange situations.

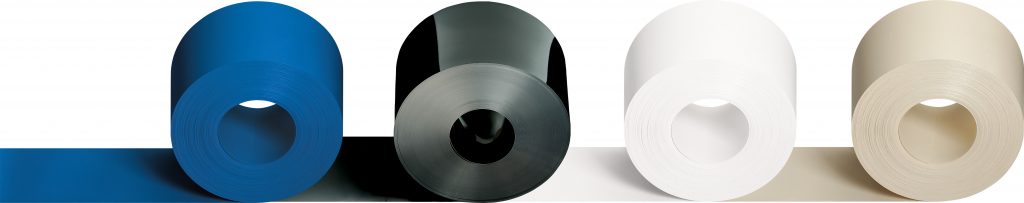

I’ll give you another real-life example: a few years ago, we launched what’s called tribo-tape which is a 0.5mm thick, or thin, plastic, self-lubricating tape. We did it in about 100mm width to start with and we developed that for the food industry, it was made of an FDA-approved material. We thought it would be great for sliding conveyors and slideways, and it is, it’s very good for that – we listened to some customers and they said that they had a demand for that in the food industry, so we made it. We launched in the UK, and we sent a mailing out to all our customers along with some samples and our first large order in the UK came from the aerospace industry. They were stamping parts out of this tape and using it within aircraft seats. This was a food-approved material being used in aircraft seats so we realised: ‘actually, there’s a wider market than just the food industry for this product, so let’s make some other materials which are perhaps more suitable for the aerospace industry – that are not coloured bright blue for instance, among other characteristics we could change.’ So, we don’t really know where the products are going to end up and it has normally taken us by surprise, it’s quite exciting.

We also approach our customers directly about that at least once a year: we have something that’s called the igus® wishlist. This is where we send an email out to everybody, it’s also on the website, telling them that anyone can submit an idea for a product to igus® and we’ll have a go at making it. We usually get some really interesting, sometimes crazy, ideas from that.

You can see that our innovation is led by the customer and our doors are absolutely open to innovation.