ROIBOT: The Low Cost Automation Robot awards Competition

Automation has become a crucial step for today’s industries: as companies strive to keep up with their competition, customer needs, and always provide cutting-edge technologies.

The Roibot robot awards competition offers the chance for Robotic systems to be put forward to show their innovation and how they are helping automate processes. Many of the robotic systems undertake monotonous and dangerous tasks , ensuring both employee well-being and profitability of small, medium or large enterprises.

Which robots can I use?

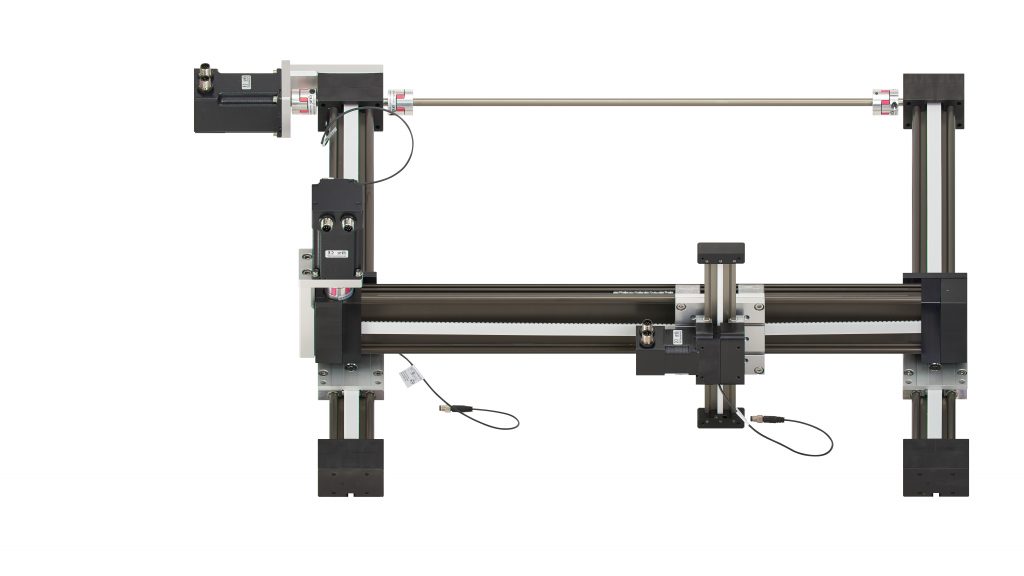

Gantry or cartesian robots are robotic systems that can move in the predetermined cartesian space along X, Y and Z; most industries are already familiar with cartesian robots and they are often used where modularity, precision and large working envelopes are required.

Articulated robot arms are best when a flexible system is required, as their degrees of freedom can be easily increased or decreased. Also, since their mechanics are inspired from our human hand, a robotic arm can access very confined spaces or pick and place products through a gate door.

Although widely used in the industry, their control still requires advanced software that can calculate the inverse kinematics to enable the robot to move along the cartesian: X, Y, Z / A, B, C. Conversely, the control system can be used to move the robot to different endpoints while keeping the TCP (tool centre point) in the same orientation to perform tasks such as welding, glueing and scanning.

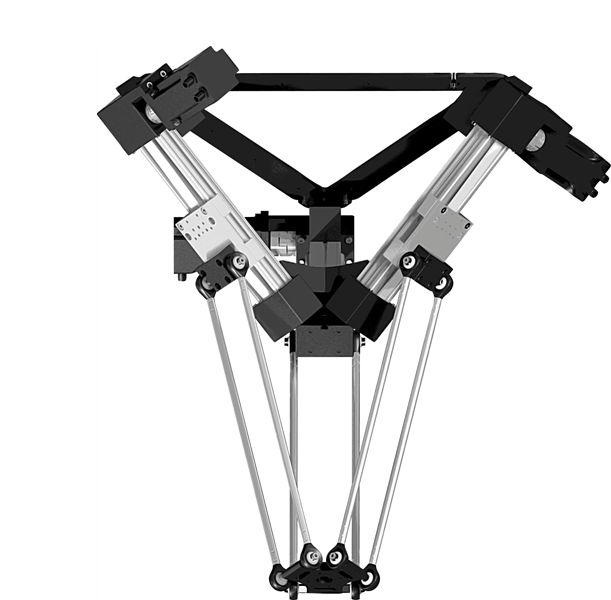

Thirdly, the delta robot is a mechanism mostly used in pick and place applications of lightweight objects at great speeds. An igus® delta robot can easily perform 60 picks per minute.

While delta robots are one of the newest additions to the robotic systems inventory, the demand for them is very high as speed and accurate positioning respond perfectly to today’s industry needs.

Although a necessity, automation continues to bear the same financial risks as other investments.

One major factor that has to be accounted for is the well-known Return of Investment (ROI).

In simple terms, each robot employed in today’s workplace incurs an up-front cost to a company, and, in time, generates some wealth in return. Once the robot has, effectively, paid for itself the ROI is achieved. Companies are therefore interested in robotic system with as low ROI as possible.

LCA: Low Cost Automation

By heavily investing in the Low Cost Automation sector, igus® has aimed to reduce the ROI and in

turn lower the investment risks for companies wanting to automate.

In order to achieve this, a combination of benefits exists within all of igus® robots:

- Maintenance-free components thanks to the self-lubricating plain and linear polymer bearings.

- Standardisation of all robot components: From a single bearing to a fully-built robotic system: all options come ex-stock, reducing lead time and manufacturing costs.

- Controlled from the D1 dryve that makes motion control easy – further lowering commissioning time through a PC, micro-controller, or an industrial PLC.

- Service life calculation for every part of the robotic system enabled by our iglidur® and drylin® online calculators to avoid downtime and increase profitability.

Wanted: Exciting applications with the robot awards

The Roibot robot awards competition is run to search for existing low-cost automation applications which have led to a quick return on investment (ROI). The following products can be used: robolink® articulated arm, drylin® delta robots and gantry robots.

Visit our website for more information about our Low Cost Automation range and for more LCA blogs visit here

Alternatively, contact the Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk with any enquiries.