Top 10 benefits of flexible cables

What are the Top 10 benefits of flexible cables?

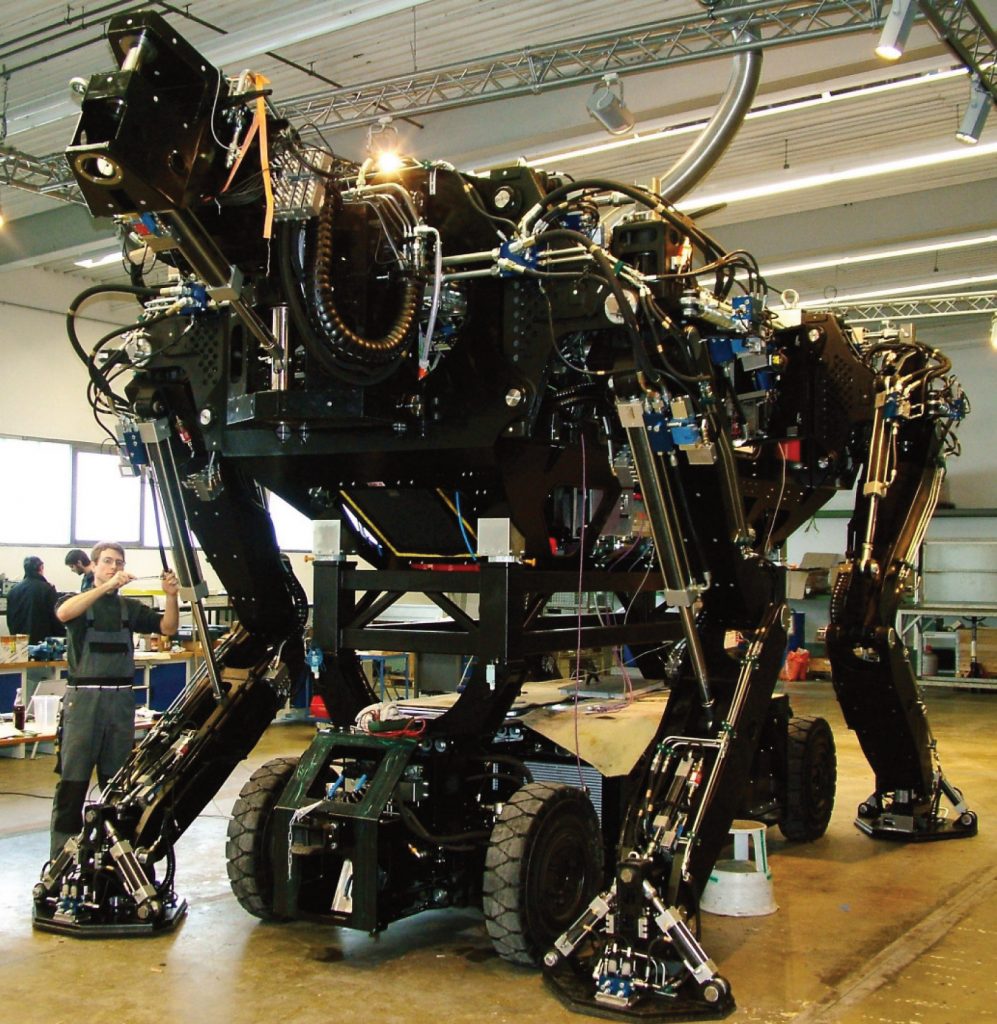

Industrial cables and energy chains are required to be able to support high and continuous flex to carry out their functions over long periods of time. The igus® chainflex® cables are ideal solutions for high speed, high flex tasks – they are able to withstand harsh conditions and severe demands from different application environments. Examples of such requirements include: large cycle numbers, high accelerations, long distances and extreme hot and cold environments.

Flexible cables for all your application needs

- Product variety: widest range of cables designed for energy chains worldwide

- Outer materials suitable for extreme conditions: high quality and durable

- Flame retardant & UL-tested

- 7 different jacket materials available

- High & low temperature capacity

- Highly durable in dynamic motions: designed for continuous life in energy chains

- Linear & torsion motions

- No minimum order quantities: order from just 1 metre

- Suitable for almost any application

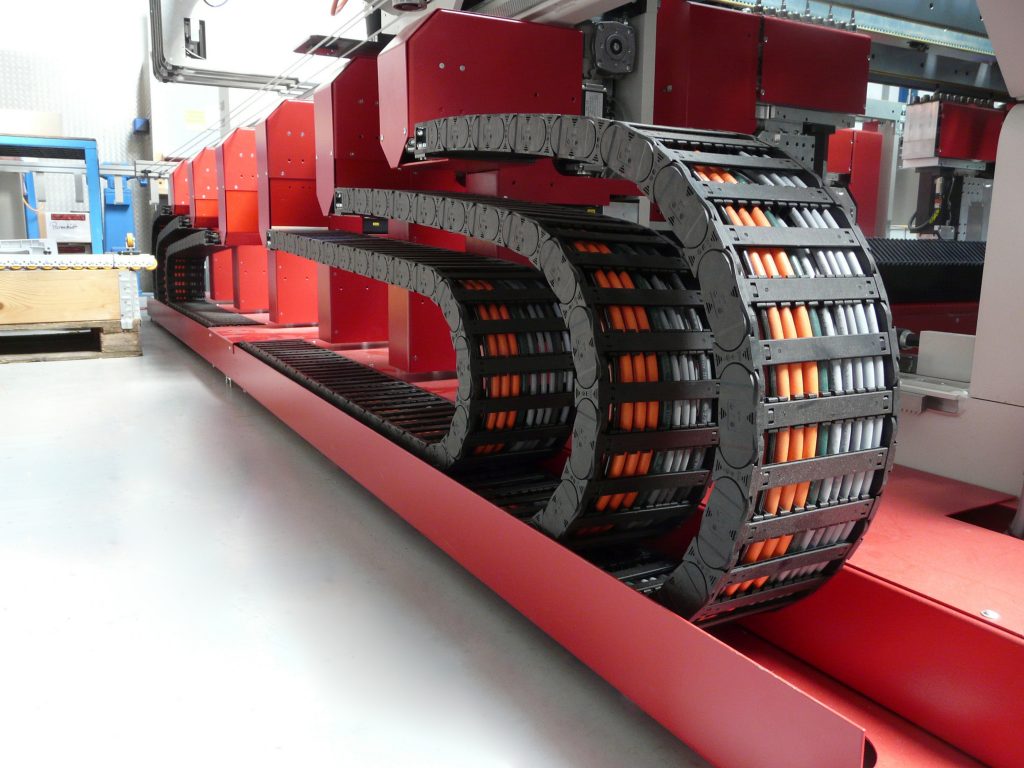

- World’s largest test facility for flexible motion cables

- On-the-road engineers providing nationwide customer support

- Superior shielding protects against electromagnetic interference/noise in high-flex applications

- Patented bundle design

- Quick delivery times: next day delivery on UK stock

Tested cables and why we have the top 10 benefits of flexible cables

Our chainflex® cables are delivered with a 36 month guarantee thanks to the 3,800m² test laboratory located in the igus headquarters in Germany. The lab features 650 tests acting simultaneously each day, which include high speed tests, small bend radius tests, and vertical climbing tests – these amount to 2 billion test cycles each year. In addition, our measuring system is fully automated, meaning there is no downtime and entirely monitored test data for each area. In this way, we monitor the change in ohmic resistance according to the number of cycles carried out by the cables, comparing the cores and fleece cores for trends. As well as the empirical data, we also obtain material results from dissecting the tested cables, then produce documentation for these.

Moreover, for fast and comprehensive configuration, you can head online to use the online calculation tools to find the right cable for every application. Thanks to being manufactured in the UK, the igus chainflex products include a variety of cable types: data, fibre optic, bus, measuring system, robot, motor, control, servo, and directly-harnessed readycables.

Visit the website to find out more about chainflex® cables.

Alternatively, contact our Product Manager John Barker: jbarker@igus.co.uk for any chainflex® enquiries.