What is just in time manufacturing?

What is just in time manufacturing?

In manufacturing, production times and costs can be the success or demise of a company, so it is important that we are all assessing and improving our production capacities wherever possible. At igus® we adopt many processes that can improve production times, therefore improving production output. In order to do this time, there is various options, one of which is “Just in time manufacturing” So, lets establish exactly what this is….

What is just in time manufacturing?

Lean and just in time (JIT) manufacturing are two concepts which were established for the benefit of manufacturing companies whose everyday processes were being actively detrimental to the development of their companies.

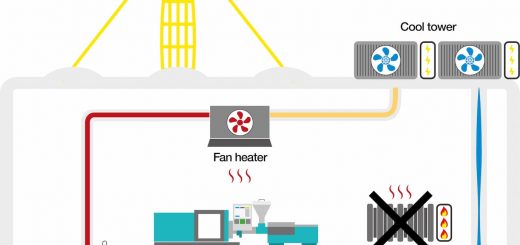

JIT manufacturing, stemming from 1960s Japanese manufacturers, is a key concept for ensuring dynamic and effective production in factories. Often referred to as the Toyota Production System, it initially arrived in the automotive industry and is today a common practice across many other industries. Triggered by the uncertain economic climate of the post-WWII era, the Japanese adopted such methods to maintain production without spending money they did not have on large inventory production and big-batch production. The leanness of this system ensures the internal skills and assets are best exploited for the benefit of future success.

The objective of JIT manufacturing is to ensure that factories will manufacture only the required products according to the orders placed and customer requirements so that surplus goods are not produced without demand. Only produce upon request!

Secondly, firms will only produce the materials or products when required so that wastage is kept to a minimum, if not to zero, and high quality is maintained due to a lower output. By maintaining efficiency, production speeds can stay high and turnaround times (TATs) can stay low. Wait for the green light!

Thirdly, companies will manufacture only the required quantity – only the amount that has been ordered by customers or according to market demand. Stop when the light goes amber!

By employing the JIT notion, companies are able to significantly reduce stagnant inventory held either as stock or as work in progress; thus, freeing up space and resources to maintain and improve cashflow, production and efficiency, keeping factories lean, organised and prolific.

Methodologies employed under JIT practices:

- Physical discipline and organisation

- Removal of defects

- Diversity of skills

- Flexible changeovers and reduced setup times

- Cellular manufacturing

- Balanced flow – limit batch sizes

- Focus on visual tools for communication

- Top-down process design

- Adjusted plant loads

- Efficient movement of materials

- Continuous improvement with Kanban boards

- Prioritise with pull systems

igus® and JIT manufacturing

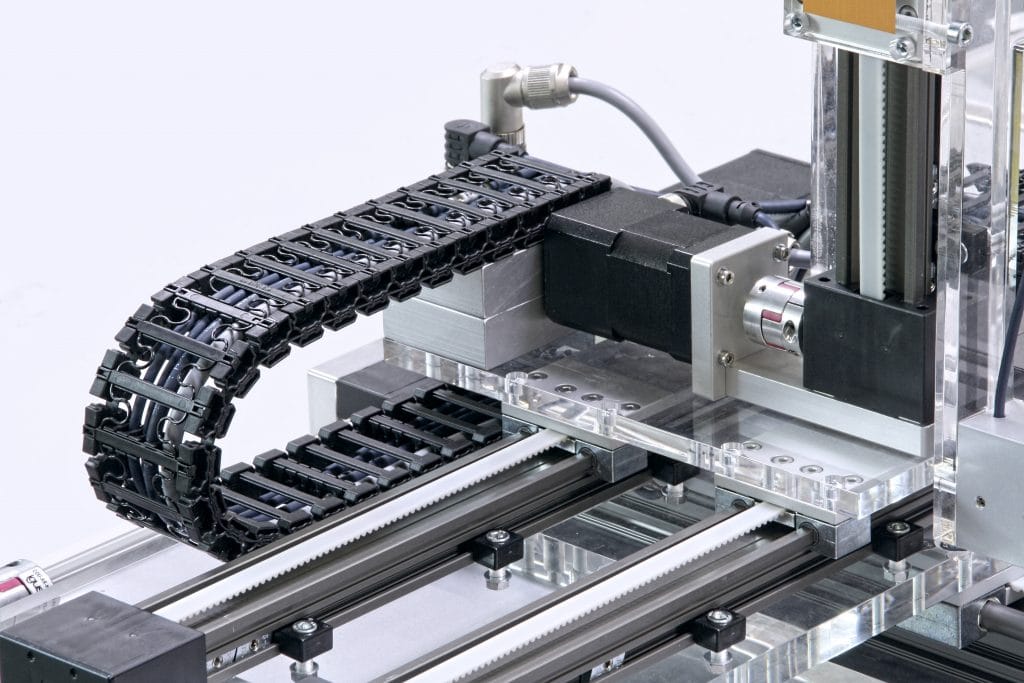

Is it clearer now as to “what is just in time manufacturing?” At igus®, we take pride in our capability to supply both our readycables® and readychains® according to JIT methodologies so that lean manufacturing is achieved at both high and low production levels.

The automated readycable® line and lean factory means we can supply our readycables® and readychains® within a 24hr turnaround from scheduled or call-off orders. We also offer consignment stock agreements on some product lines. If you want to read more about this, take a look at this blog https://blog.igus.co.uk/what-is-consignment-stock-and-who-needs-it/

Launched at the close of 2019, the new readycable® line utilises lean manufacturing methods to improve competencies and accelerate production of our manufacturing processes.

In addition, these products are available on as small or as big an order as you require since we have no minimum or maximum order quantity for them – as well as being delivered to you on a bespoke rack.

For more blogs on similar topics visit and if you want to talk to an expert in this area please contact us.