Which is the best solution for your SCARA robot?

What is a SCARA robot?

A SCARA is a type of industrial robot which is becoming increasingly popular for use in small robotic assembly applications. There are two acronyms for these robots; Selective Compliance Articulated Robot Arm or Selective Compliance Assembly Robot Arm.

The SCARA consists of two arm joints, interlinked at the base, known as a parallel-axis joint layout. One of the arms is compliant in the X-Y direction but rigid in the ‘Z’ direction and this is advantageous for many types of assembly operations. Operations where the footprint needs to be smaller than that of Deltas or Cartesians.

Similar to a human arm, the SCARA has a jointed two-link arm layout which is why it is often referred to as an “Articulated” arm. This feature allows the arm to extend and retract into confined areas. This is advantageous for process applications, where you need to transfer, load and unload parts from one cell to another.

SCARAs are generally one of the faster robot systems. Their single pedestal mount requires a small footprint, and given that many of the applications for these robots would be pick and place, they are ideal. You will also see SCARAs used where high speed and accuracy are required. Despite this, they are not designed to be capable of high payloads so this needs to be considered. Another factor is SCARAs can also be more expensive than comparable Cartesian systems. Furthermore, the controlling software requires an in-depth knowledge of the kinematics that go into programming.

What can igus® offer?

igus® has just released a version of a SCARA robot! This is brand new and more will follow on this but this blog is to look at the cable management options.

Read about how to prevent breakdowns with igus® cable management here.

In relation to cable management, we have 3 different options which we shall refer to as:

- Basic

- Better

- Best

Basic

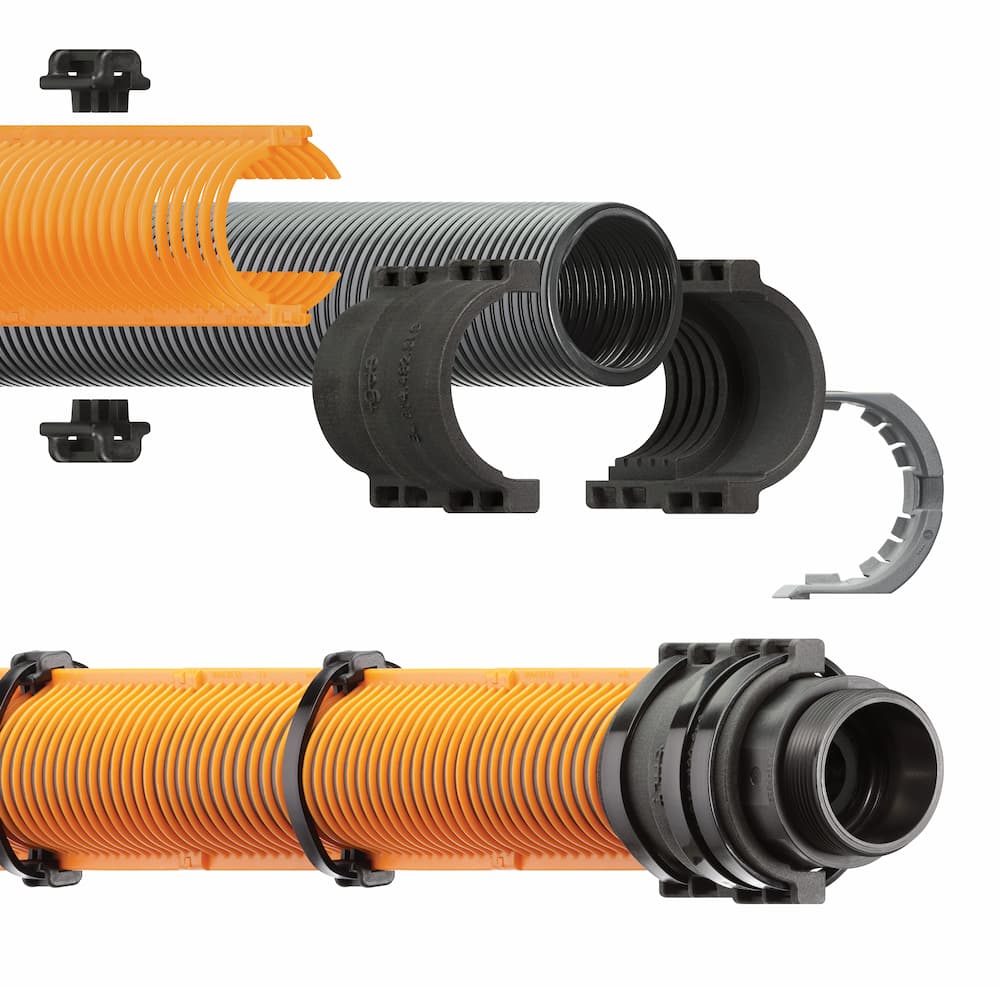

The basic solution is a corrugated hose with connector option. This comes in various sizes and has excellent temperature range capabilities from -50°C to +95°C. These hoses are extremely flexible and are used in a wide range of applications.

Better

The better option is the above corrugated hose with connectors, fitted with the igus® e-rib Solution. The e-rib is a reinforcement for corrugated tube systems. This stabilises the hose ensuring it only moves in one direction. Here are some advantages summarised:

- Little installation space required

- Can be easily retrofitted

- Independent of hose manufacturer

- Stability prevents unintentional sideways movement

- No detrimental change to the impermeability of the corrugated hose

- Three sizes for nominal hose widths NW23, NW29 and NW36

Best

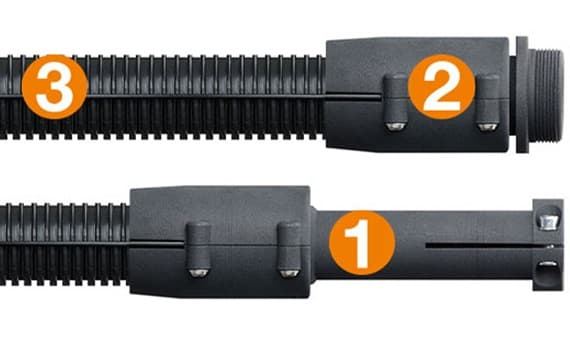

Finally, what we consider to be the best option, consisting of all of the above elements but with optimised connectors. igus® specifically developed the e-rib for corrugated tube reinforcement, combined with igus® rotary bearings at either end. This was to provide a long-lasting, protective cable and hose solution

The complete SCARA cable solution consists of 3 elements. These elements match the respective SCARA robot or are adapted to suit it.

- Rotary bearing, moving end.

- Rotary bearing, fixed end.

- Corrugated hose with e-rib.

We have been supplying SCARA cable solutions for years and have done extensive testing on the various suitable options.

If you have a SCARA application that requires cable management, please get in touch!