Is the beverage industry growing?

‘The UK’s food and drink industry is the country’s biggest manufacturing sector by turnover, valued at £104.4 billion. It is larger than the automotive and aerospace industries combined.’ – www.great.gov.uk

So, it’s no surprise that the beverage industry is growing especially when trends such as health and wellness, sustainability and personalisation are considered.

- Health and wellness: In the age of social media where trends spread like wildfire, consumers are shifting their focus to healthy practices. As a result, beverages that offer health benefits from energy to immune boosting or improved gut health have become a popular purchase

- Sustainability: Companies are becoming more aware of their impact on the environment and the appeal to environmentally conscious consumers of eco-friendly packaging and sustainable practices. Providing sustainable packaging and sending a clear message on your brand’s intent to reduce environmental impact is a way to impress consumers and benefit from these values aligning.

- Personalisation: Consumers are seeking more personalised options, tailored to their individual preferences and health needs. Consumer needs are constantly evolving, and the lengths businesses must go to, to catch their target audience’s attention is becoming more complex.

The industry is adapting to these changing consumer preferences and technological advancements, and this is fuelling its growth.

Molson Coors investing in the beverage industry

Spanning the next 5 years, Molson Coors Beverage Company are set to invest more than £100 million in their UK business infrastructure.

A decision made as a result of their brands’ strong performance, the investment is enabling the company to expand upon its brewing and packaging capacity.

“This plan is an investment in our future, giving our people and our brands the tools to fulfil our potential in the U.K. market while making strong progress against our sustainability targets,” Fraser Thomson, Molson Coors’ chief supply chain officer for Western Europe. 1

This £100 million plan focuses on improving their largest facilities in Burton-on-Trent and Tadcaster, with the Burton brewery getting a new 24-tonne high-speed can filler that can fill up to 120,000 cans per hour.

Although the investment and infrastructure upgrades will enhance capabilities and boost the efficiency of Molson Coors’ U.K. network, they will also be crucial in helping the company achieve its goal of reducing direct carbon emissions to net zero in the U.K. by 2035.

“This is a landmark moment in our history as we evolve to meet the demands of our growing portfolio and bring new innovations in the years ahead, while continuing to reduce the impact our business has on the environment,” Thomson said.

igus® in the beverage industry

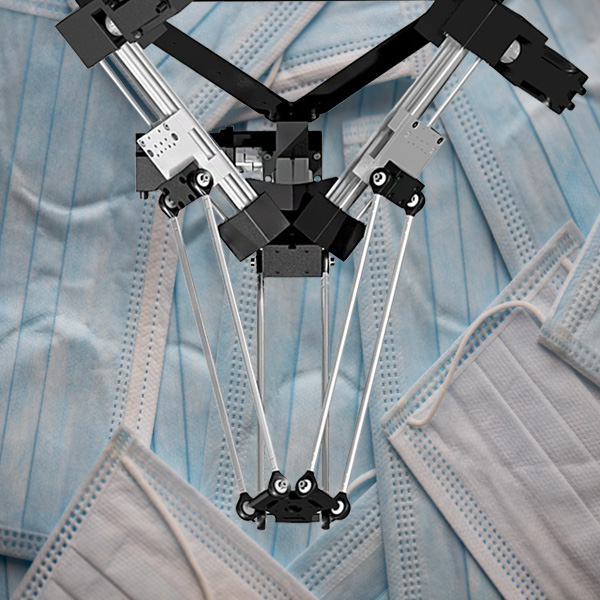

The need for flexibility in modern production systems is rapidly increasing. igus® have multiple solutions to improve the efficiency of production lines from an articulated arm robot with a control system for easy programming that takes on monotonous pick and place tasks to a range of FDA compliant products designed to be maintenance and lubrication-free.

Articulated arm robots

The articulated arm robots can undertake a variety of time-consuming tasks that frees up people to focus on highly skilled tasks that acquire more attention. This robot is designed to operate with grippers from different manufacturers, with the design also available in a colour of your choice.

Key features of the articulated arm robot:

- Up to 3kg payload

- Plug-and-play control hardware including free software

- Short delivery times

FDA Compliant products

In the beverage manufacturing industry, machines are subject to constant use and high demand. They must comply with hygiene regulations, ensure operations run smoothly, and endure harsh cleaning agents.

igus® machine components are made using high-performance polymers and are designed to meet these challenges. They are abrasion-resistant, lubrication-free, and resistant to both chemicals and corrosion.

Key features of these components include:

- Low moisture absorption

- Easy to clean

- Save installation space and weight

- Easy assembly

To find out more about automation and where it could fit into your business, take a read of our other resources.