How can you control friction in an application?

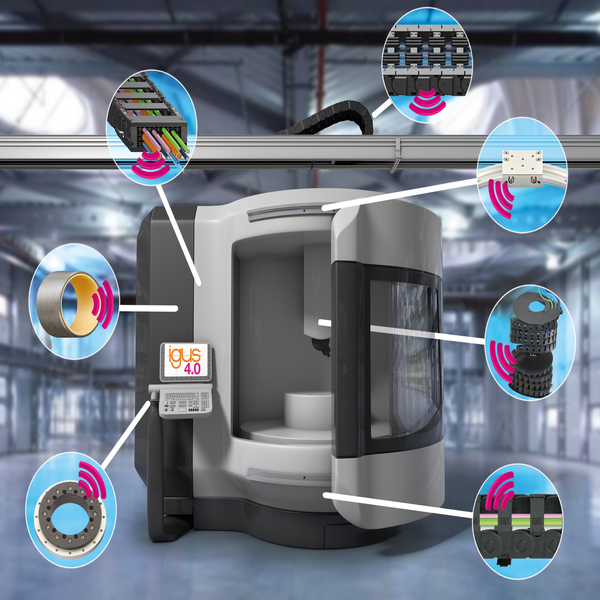

At igus®, we spend our time investigating how best to reduce and control friction or create products and solutions using our high-tech polymers to attain minimal friction in applications. The goal always seems to be to make sure that the carriages are running freely on the rail or ensuring the shaft runs smoothly through the bearing. Despite this requirement for “free-running”, what happens when you need to control friction?

Luckily, igus® can cater for both sets of requirements. But, how can you control friction and within one product range? drylin® W is how.

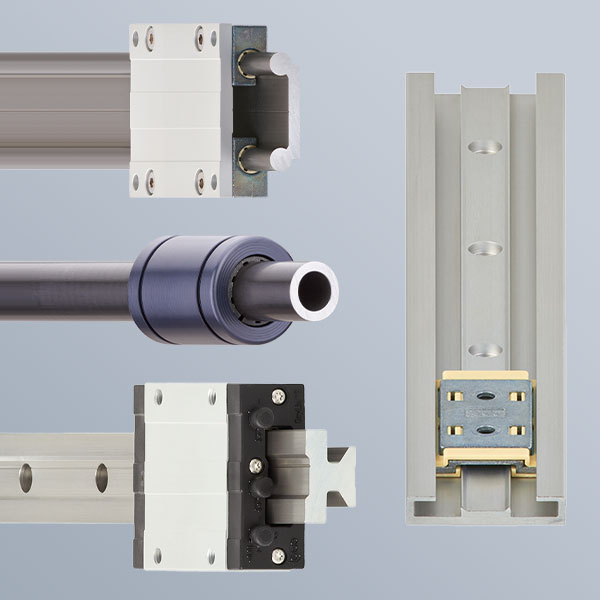

Within the complete linear range drylin® W is our largest linear product range and with this, allows us the most flexibility. The extensive variety of products and its modularity allows for freedom to fulfil the application requirements.

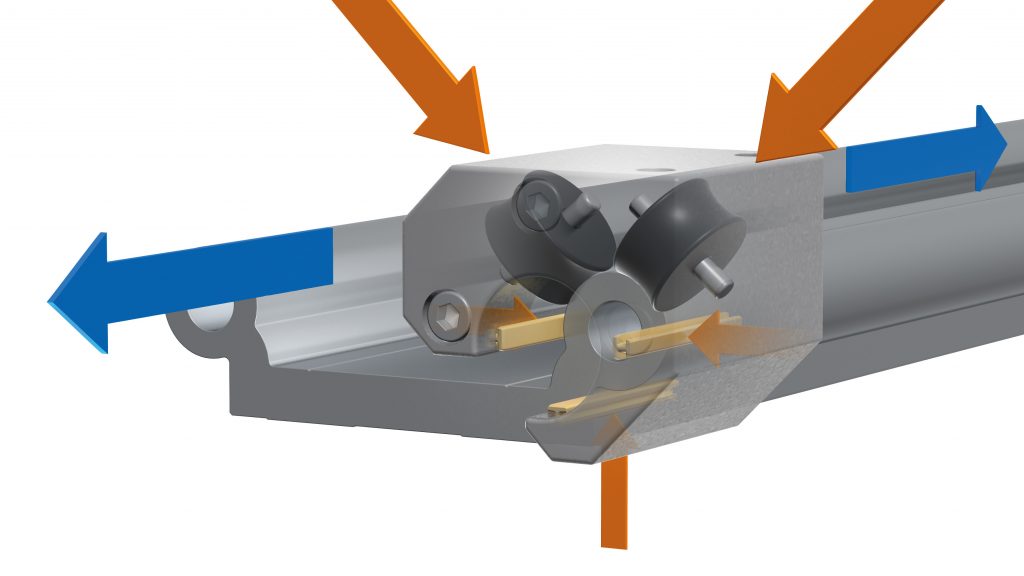

A little gem within the range are the new pre-loaded carriages, WJ200UM-01-10-PXXX

These carriages allow friction to be controlled without having to manually adjust the required parameters. Below we highlight why these might be perfect for your application but also identify which products can do the complete opposite…..

Why would you need to control friction in an application?

When we think of friction, what do we think of? Do we think of a push and pull force? At times this might be exactly what we need:

Image that you are on a train, you slide out a table tray in order to put your laptop on to answer your emails. Now imagine that, as you are frantically typing away, the tray starts to retract and slowly but surely the laptop soon has no surface to stabilise on and it comes crashing down onto your lap. Far from ideal. This is a prime example un-controlled friction. To prevent this from ever occurring, we offer the pre-loaded carriages. They are equipped with small springs within the housing which keeps the torsion of the housing in its desired position. The springs are colour coded, which makes the strength of the spring easily identifiable.

Other examples of where friction is paramount: Headrests, you want the headrest to be put into a position and then you want it to stay in that position! Without controlling friction, the headrest would fall under its own weight. The spring-loaded housings come in 4 different spring torsions and in various sizes. They also come in 3 different housing materials: zinc, aluminium and stainless steel so we can cater for most applications.

Why would you not want to control friction?

Many situations require very little friction. One example of this would be: Manually operated door systems. These need to be operated by hand and to ensure that the operation remains within the realms of health and safety, it needs to have very little friction. If friction is too high, the people operating the doors could find themselves with repetitive strain injuries. No one wants that, neither the operators nor the employer.

Of course, igus® has a solution for this! Our hybrid rollers are perfect. They have integrated rollers which enables smooth running. They require zero maintenance, have a low driving force and are lubrication free. These are the ideal housings for the manually operated door systems. Very little force is required so there is no straining for the operator and like the spring-loaded housings, they are available in varying sizes and materials. Our latest version released is a stainless-steel version, an extremely robust, corrosion- resistant housing which are renowned for their quietness.

For more blogs on drylin® products please visit https://blog.igus.co.uk/category/dry-tech/drylin/

No matter what issues are thrown at us, igus® has the solutions. If you have an application where you need our help, contact us and we will be eager to help!