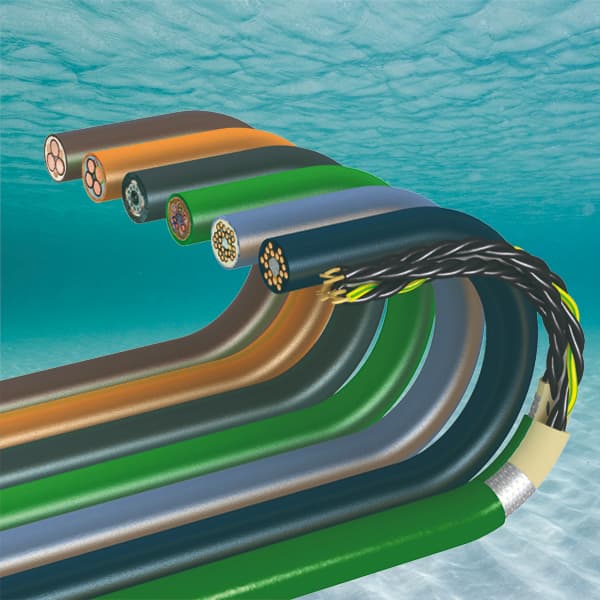

How can FDA bar stock material help your application?

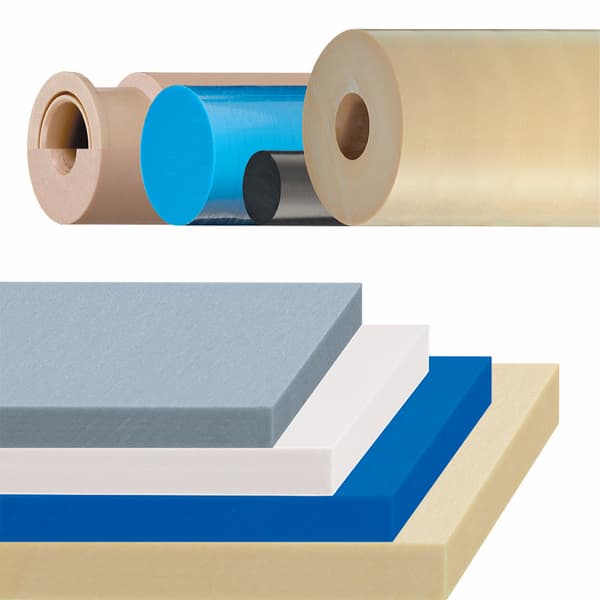

igus® has a large range of FDA approved products, in both the chain range and the bearing. However occasionally the standard range might not quite fit the design so having a large range of stock materials enables customers to be as creative as they desire.