For more information on slewing ring bearings, visit www.igus.co.uk/PRT

What are key features of slewing rings?

There are endless opportunities for these PRT slewing rings, in all kinds of applications and some of the key features are:

For example:

Completely maintenance-free

Easy to install and replaceable sliding elements

High wear resistance

For very high loads and high stiffness

Stainless steel versions available

Extensive accessories available, such as hand clamps and position stops.

FDA options available

Bespoke and full integration enquires welcome

What industries are the slewing rings used in?

The PRT slewing rings are used in multiple of industries. Furniture manufacturers, Material handling, Food and Packaging to name a few.

What do igus® call their slewing ring range?

We call our slewing rings the PRT range.

Which orientation can the PRT’s be assembled?

PRT’s can be mounted horizontally and also vertically so very adaptable.

Do igus® offer a collar clamp for the slewing rings?

Yes, the PRT-01-20-C is equipped with a collar clamp

Can you offer a stainless steel PRT?

Yes we do. Ours is ESD Compliant and comes with maintenance free sliding elements out of iglidur® F2. The part number is PRT-01-XXX-ES-F2

What accessories do you offer?

We have various accessories:

Manual clamps, drive shafts, distance ring, the individual gliding pads, clamping level, adaptor plate, angle stop sets. Please click here to see all available accessories.

Are there PRT slewing rings for use in ESD or ATEX environments? Are PRT slewing rings electrically conductive?

For use in ESD or ATEX areas, we recommend using iglidur® PRT slewing rings with stainless-steel rings and sliding elements made of iglidur F2.

Can I get PRT slewing rings that are FDA-compliant? Are PRT slewing rings suitable for use in contact with food?

Yes. As an option, iglidur® FDA-compliant PRT slewing rings with iglidur® A180 plain bearings and stainless-steel rings are available.

What is the heaviest load to which I can subject iglidur PRT slewing rings?

This depends on the size of the slewing ring. The maximum permissible load on the currently largest iglidur PRT, PRT-01-300, is 150 kN statically in an axial direction, which corresponds to a weight of 15 t. During movement, the permissible load is 90 kN. For the smallest model, PRT-02-20 – for applications with small loads and simultaneously high pressure of costs –, the maximum load is 13 kN statically and 4 kN during movement.

What is the maximum possible speed for PRT slewing rings?

The maximum speed depends on the size. For the largest possible iglidur PRT slewing ring, PRT-01-300, this is 50rpm; for the smallest, PRT-01-20, it is 300rpm.

Why do you have a square version of the PRT?

The square version is for very high loads and offers a high rigidity. It is easy to install and makes replacing the sliding pads easy.

Do you do an ESD slewing ring?

The PRT-04 ESD has iglidur® F2 sliding elements which avoids the electrostatic charges. It is stainless steel so conductive and protects against electrical currents.

What is the new PRT-04-50-T?

The new PRT-04-50-T is a new slot nut profile PRT which allows add-on parts to be added and mounted retrospectively. Perfect for the medical industry

How does the i-sense work with the PRT’s?

i-sense is the smart bearing technology which allows production monitoring making it “predictive”. The sensors can be operated as a stand alone system or can be integrated within the production infrastructure.

With the PRT range, the sensor measures the abrasion of the sliding elements and alerts when there starts to have wear allowing you to replace before the part starts to fail.

How big are the tolerances of the PRT slewing ring bearings?

The PRTs’ range of tolerance is independent of size and amounts to 0.25 millimetres both radially and axially.

The axial run-out is also independent of size and indicates the maximum height difference for a cycle. It amounts to 0.1 millimetres. The radial run-out indicates the maximum deflection in radial direction during one circulation, and amounts to 0.2 millimetres, independent of the installation size.

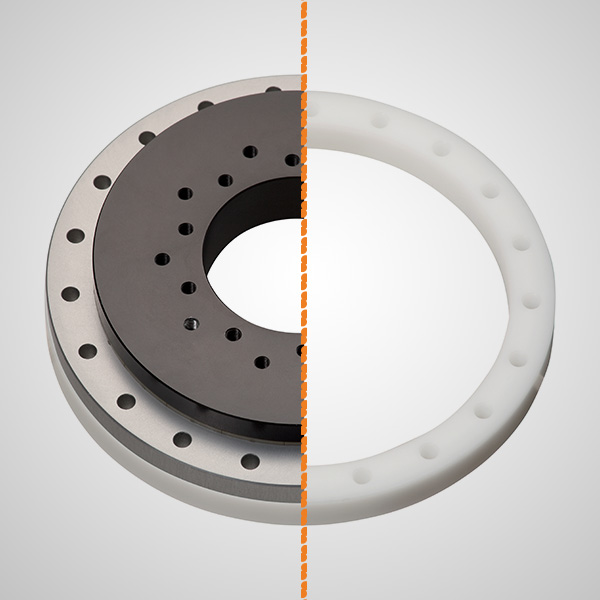

What are the differences between a PRT-01, -02, -03 and -04?

We can offer you four different PRT slewing ring series. Each series has its own strengths.

The PRT-01 is the classic slewing ring bearing. Due to its robust construction, it is characterised by a high torsional strength, and is the most durable PRT. The variety of designs ranges from a stainless-steel version with iglidur® F2 sliding elements for ESD conformity to different gearings.

The PRT-02 was developed to save as much weight as possible. With an outer ring made of anodised aluminium and two iglidur® J4 collar clamps, it is the lightest PRT slewing ring bearing, and also very resilient and rigid.

The PRT-03 was specifically designed for the low-cost market. Through consistent downsizing, an additional design has been created that relies even more on plastic. This economises on costs, but not on performance.

The PRT-04 is the high performer in our product range. It is 60% lighter, 50% more compact and 20% more cost-effective than PRT-01. In addition, you will benefit from an extensive and ever-growing modular system. You can find an overview on our website or in our catalogue – alternatively, you can watch our .

Is it possible to drive my PRT with an engine?

In our product range, you can find different slewing rings with drive for robot joints.

In addition, we offer four different gears of the outer ring for our PRT-01 and PRT-04 slewing ring bearings. For a toothed belt drive, you can choose between the conventional toothed belt profiles T10, AT10 or HTD8M. Furthermore, a classic spur gearing according to DIN 3967 is available.

For an even more compact design, the PRT-04 is also available with a toothed inner ring according to DIN 3967.

Is 300mm the largest diameter available?

Yes, 300 millimetres is the largest available diameter. However, it is possible to purchase universal sliding elements for the series PRT-01, which are suitable for slewing rings with a diameter of 500 to 5,000 millimetres.

Can I combine the different PRT models with each other?

Yes, you can. Our PRT-04 modular system is continuously growing, and gives you the possibility to combine different functions. Please contact us in this case. Choose your preferred means of contact and .

Are there any requirements for the surface in the bolting area?

Yes, the flatness must be 0.05 millimetres and the surface should have a hardness of at least HBW 50.