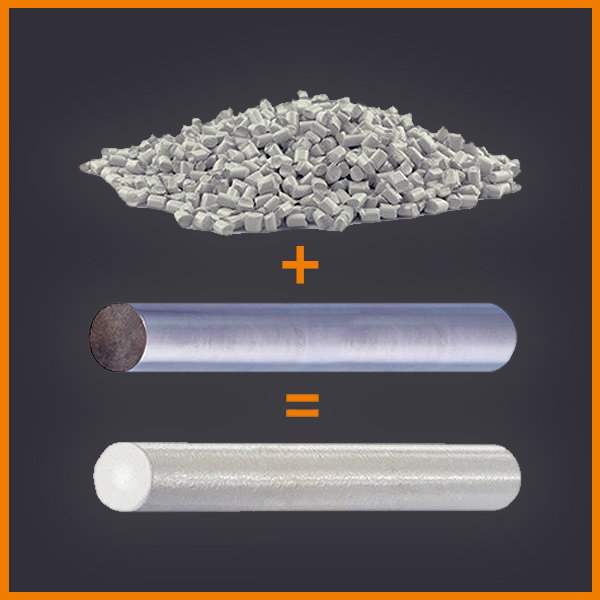

iglidur® Q2E; the ‘evolution’ of iglidur® Q2

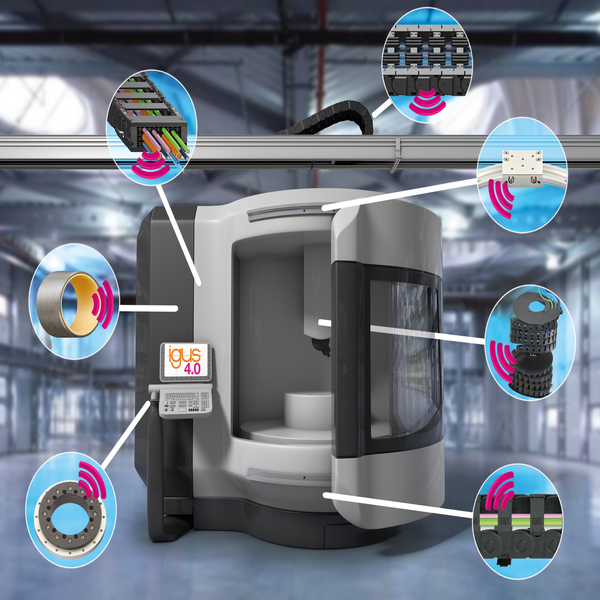

Evolution is essential to ensure that the best product is being provided at all times. The evolution of iglidur® Q2 into the new and improved Q2E allows better wear for lower cost. Not only that, igus® have created a bearing that is smart…