For more information about e-chains® visit igus.co.uk/energychains.

How do I specify an energy chain?

There is certain basic data that is required – the diameters, weights and minimum bend radius data for the cables and hoses. Also, the application data, such as machine travel length, speed, acceleration and even the environmental conditions. Service life calculations can be obtained with our online tool here.

At igus®, we have online expert systems to help offer the available options for these inputs and show respective lifetimes and costs. Of course, we can also support by phone, email, Livechat and visits to your site by our engineers.

What accessories or extras can I get with igus® energy chains?

igus® also offers a wide range of dynamically rated cables for use in constantly flexing applications (“chainflex®“), which are guaranteed for 10 million movements or up to 4 years when used as per our guidelines. These can be supplied with or without connectors and pre-fitted into the energy chains. We also offer steel and aluminium guide troughs for longer travels, cable clamping solutions for cable strain-relief and chain interior separation options to ensure a long cable life inside the chain. We also offer design and project support, onsite services such as supervision and inspection and full turnkey installation.

I have used steel chains in the past, would an igus® energy chain be able to cope with the high fill weights used offshore?

igus® e-chains®, or energy chains, can cope with fill weights of up to 600 kg/m unsupported.

Find out more about igus® components for the offshore industry here.

Can I replace a single cable within an e-loop®, rather than having to replace the whole service loop?

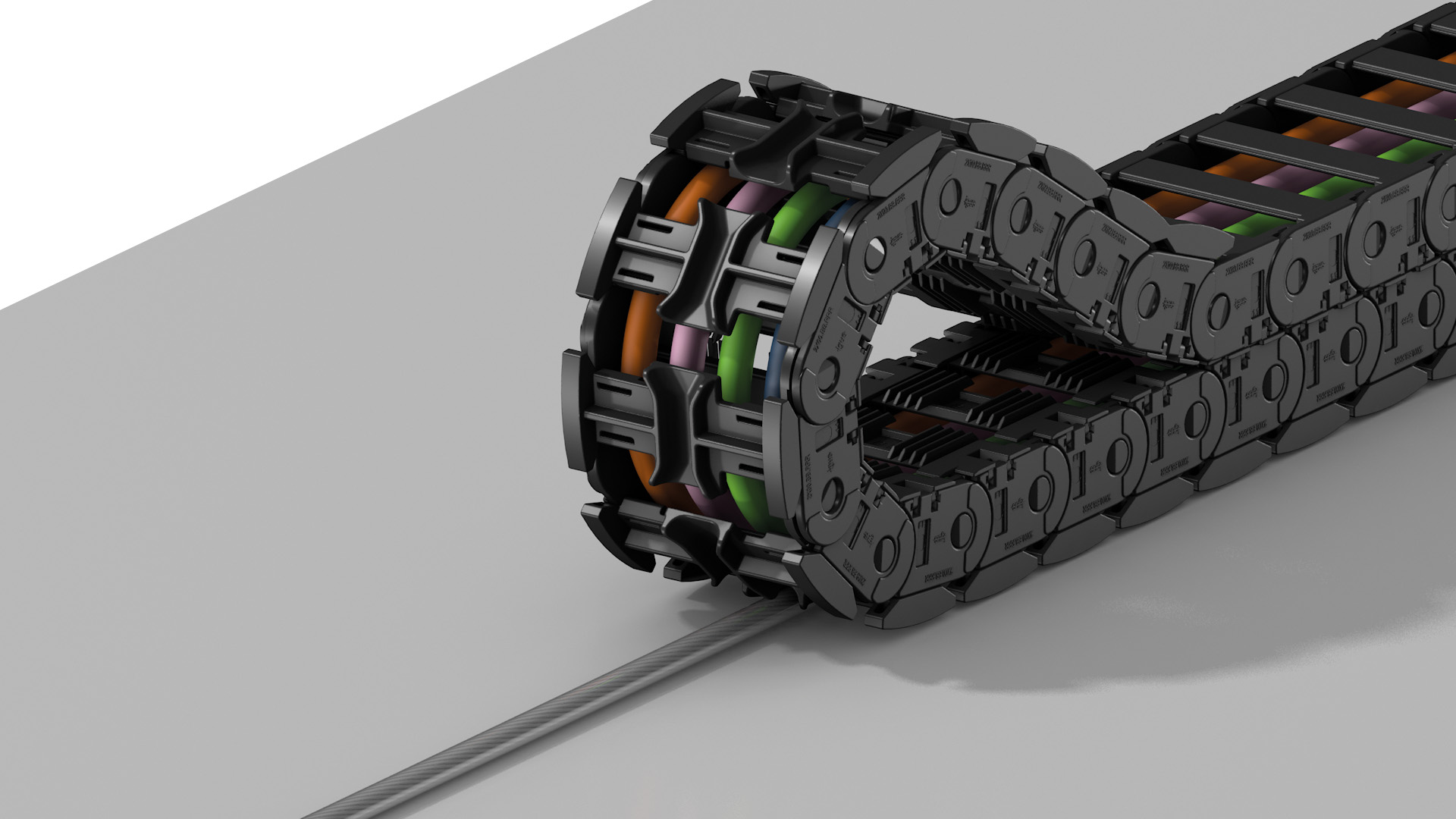

igus® e-loop has been designed to enable the operator to replace single cables/hoses in situ, rather than having to replace the full service loops. The e-loop is built up in links, which can be opened to allow the cables to be changed. The dyneema rope which runs through the middle of the e-loop is pre-tensioned to the working load, and so takes the strain of the cables or hoses in use.

We already have an existing service loop, and do not want to have to engineer new brackets to fit an igus® e-loop®, can igus® help?

Yes! igus® e-loop is supplied with an industry-standard mounting bracket and flange, as per on major OEM top drives, so it is a simple and quick retrofit!

We currently use stainless steel energy chains offshore, isn’t that the industry standard?

igus® has thousands of energy chains on existing applications offshore including cantilever skids, pipelay towers, gantry cranes, and many more as seen here. Our polymer energy chains are maintenance-free, corrosion resistant, and cost effective vs equivalent steel chains.

We have an existing steel chain offshore, can this be retrofitted with an igus® chain?

Yes!

igus® can carry out offshore surveys on existing chains/cable management solutions and retrofit them with a new maintenance free igus® energy chain! We offer a complete turnkey engineered solution to suit our customers’ requirements!

Are energy chains suitable for hydraulic hoses?

Although igus® does not manufacture hydraulic hoses, the hoses can be sourced and installed within your e-chain® to your requirements.

Our online tool prevents our customers from over filling the e-chains®. We have recommendations for the amount of clearance each service should have when installed within the e-chain® (relative to its OD); 10% for all round and flat cables, 5-10% for pneumatics, 20% for hydraulic hoses and 15-20% for all other media hoses.

Who needs energy chains?

Almost every industry with moving energy requires energy chains: cranes, lifts, theatres, vessels, machine tools, renewable energy systems, electronics, pick-and-place machines, telescopes, agriculture, printing, vehicle sliding doors, and so on – the list is endless.

What is the maximum travel length I can do with the Autoglide-5 energy chain system?

The maximum travel length is currently 80M.

Can I run different services down the same energy chain system (power, date, pneumatic)?

Absolutely! Find out more here.

Do I need to do regular maintenance as I do with my current bus bar and replace serviceable parts?

No, a visual inspection is required every 6-12 months and adjustment of cable tensions (if necessary).

How long does it take to install the Autoglide-5 energy chain system?

88% faster installation time than standard chain.

Can I monitor the condition of energy chains on the computer?

All igus® energy chain sensors (push/pull monitoring, abrasion, motion, wear measurement, break detection) can be connected to an icom or icom. plus module. The module can transmit the measurement data to an equipment monitor or a computer, where they are displayed individually or in a dashboard.

Which energy chain do I need?

We have a configurator tool and a product finder tool which will help you specify the energy chain required.

Click here for the product finder.

Click here for the configurator tool

Are there energy chains with FDA approval?

Yes. We recommend the TH3 energy chain, which has been developed specifically for the food and beverage industry.

What energy chains are suitable for ESD applications?

You can find all energy chains made of conductive ESD material here.

Can igus® energy chains be used in the deep-freeze area?

Yes, all igus energy chain materials can be deployed in continuous use at temperatures as low as -40 °C.

Can I implement a long travel energy chain even without a guide trough?

Yes, the autoglide system allows travels of up to 80 m without guide troughs.

Are plastic energy chains resistant to hot swarf?

Yes, plastic energy chains that use the igumid HT material can resist swarf as hot as + 850 C.

Are energy chains chemically resistant?

A detailed list provides information on the resistance of igus’s igumid G, TE, and NB materials to many chemical substances.

How high is the standard temperature range for plastic energy chains?

As a rule, the standard temperature range for plastic energy chains is -40 °C to +130 °C, short term +170 °C.

Which energy chain type serves as the basis for the new autoglide 5?

The basis is the model 2400 with 77mm width and 75mm bend radius. Other widths and radii are of course also possible. Find out more about autoglide 5 here.

Can I replace the energy chain crossbars if they wear out?

Yes, because the special crossbars can simply be opened. Should they ever wear out, they can be easily replaced.

What is the service life of the autoglide 5 energy chain?

As with all the igus® e-chains®, we aim for 10 million cycles or 10,000km. The tests for a guaranteed statement are still running in our laboratory.

How long is the service life of an e-chain®?

You can discover the service life of igus® energy chains using the service life calculator.

What is the purpose of a cable drag chain?

The purpose of igus® cable drag chains are to guide and protect cables in moving applications. Find out more about our drag chains here.

How do you install a cable drag chain?

igus® can support you with installing your energy chains, simply fill out the form here, or call 01604 677240 to request an installation.

What material is the igus® cable track made of?

igus® energy chains are made from high-performance plastics.

Read our energy chain blogs here.