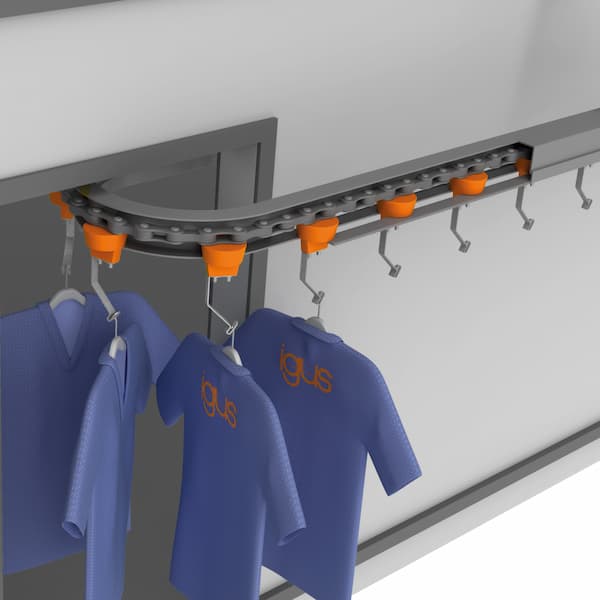

The top 3 benefits of using overhead conveyor systems

Overhead conveyor systems are probably not used enough. Instead we, as a society build bigger facilities, decreasing the space we have left on this planet. But if every company went up and used the ceiling space, we could double the productivity without doubling the building footprint. Could your business use an overhead conveyor system? Read more here.