Motion plastics at igus®

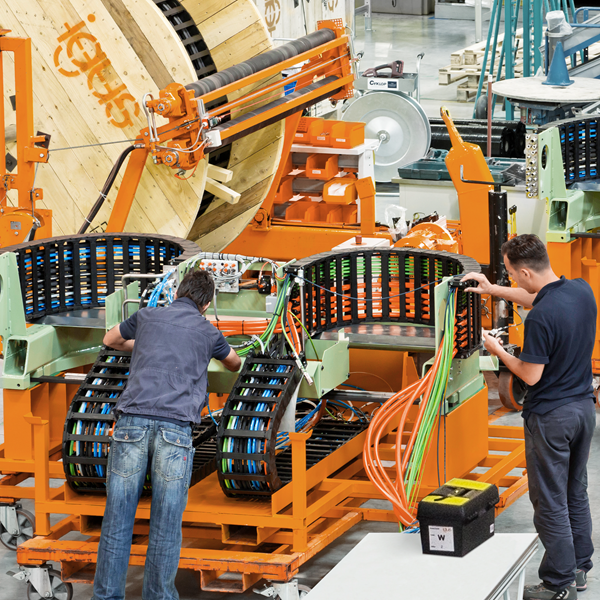

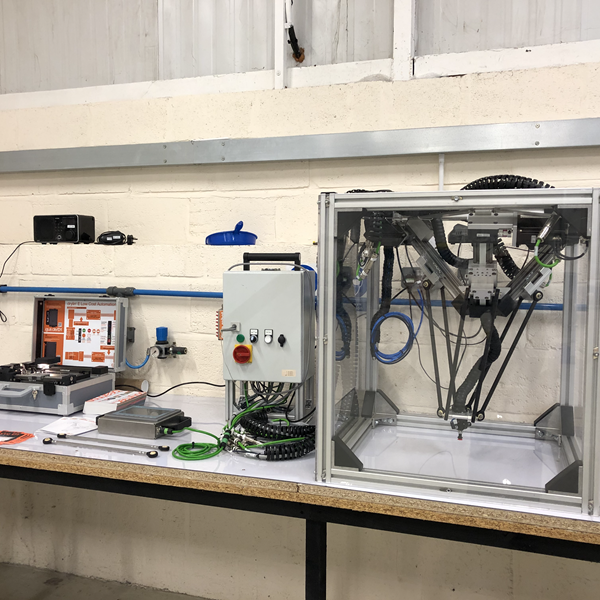

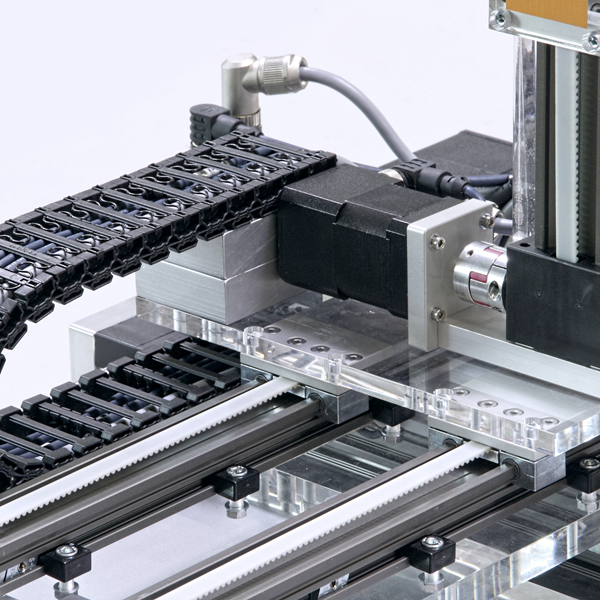

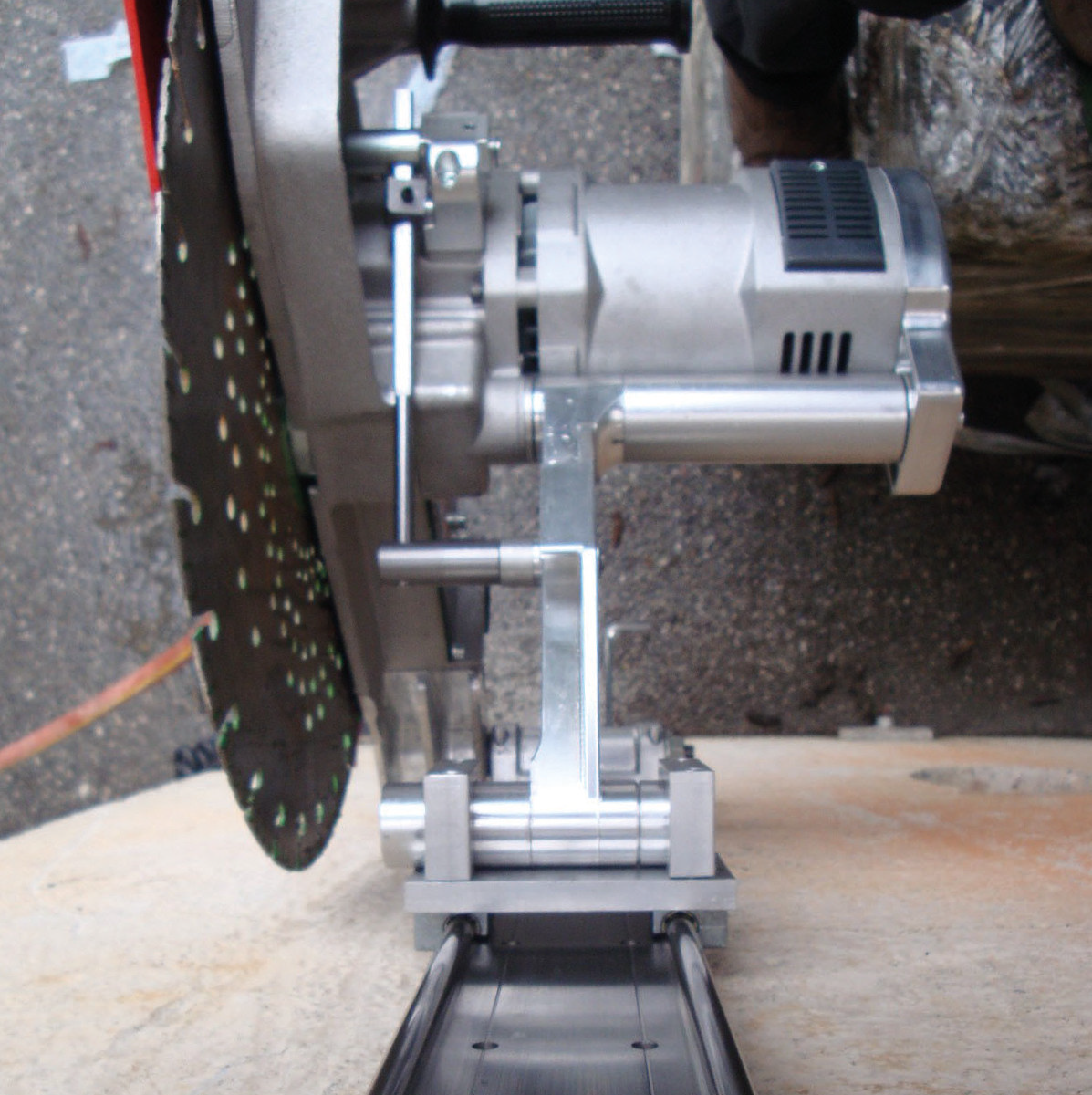

Our essence is motion, so if your machine has moving parts igus® can promise a number of things. The product we offer will be: self-lubricating, maintenance-free, cost-effective, predictable, resistant to dirt, dust, chemicals and heat (to name a few), and will improve the lifetime of your machine too.