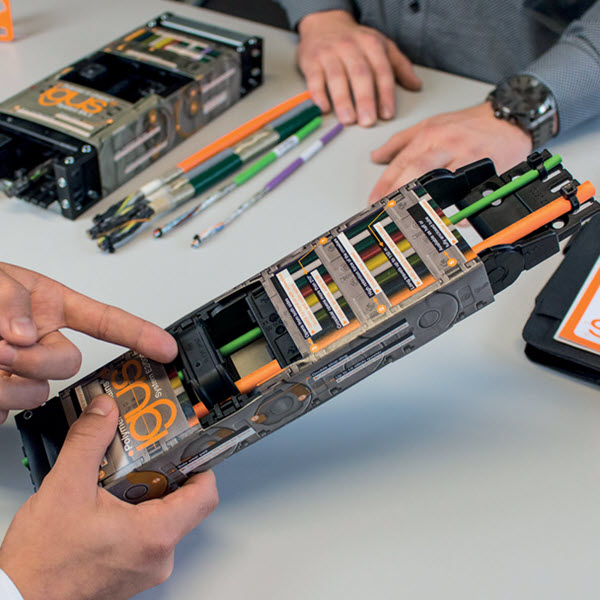

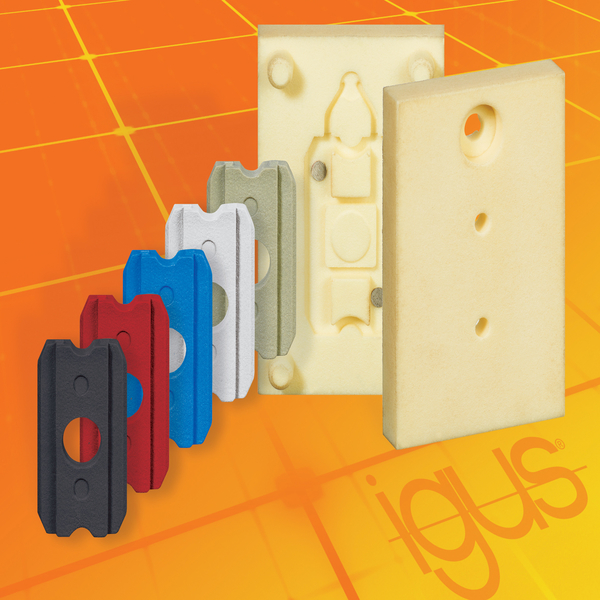

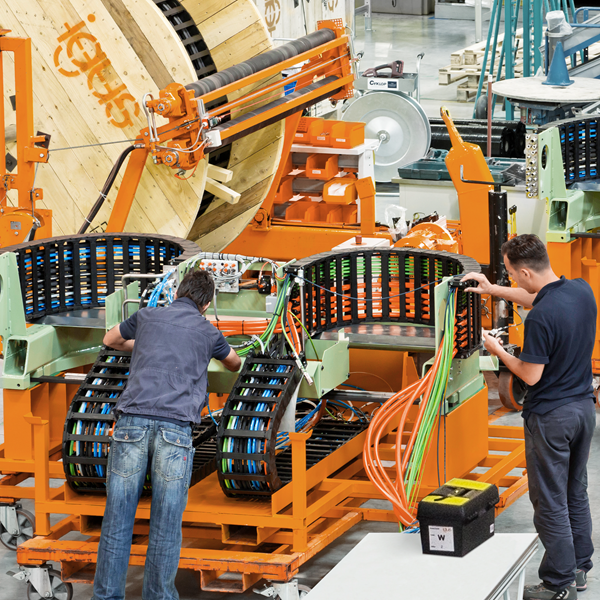

Samples aplenty!

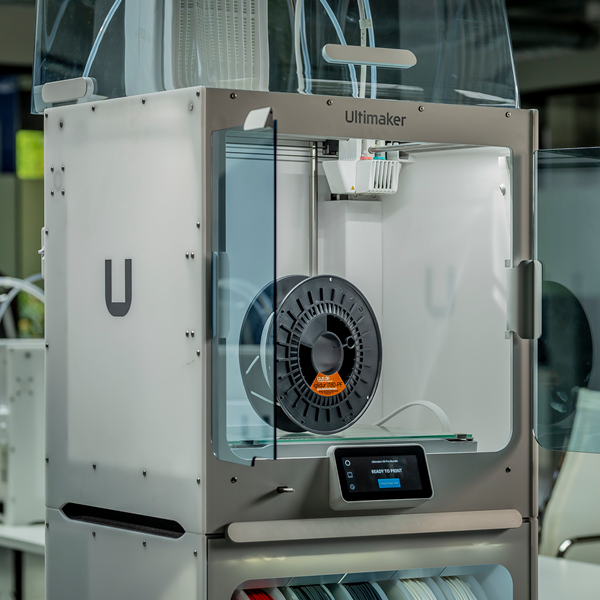

At igus®, samples are a part of our way of life and for our product development and industry growth. We find that samples allow us to demonstrate the latest technology and versatile product capabilities with an abundance of product types, properties and functions.