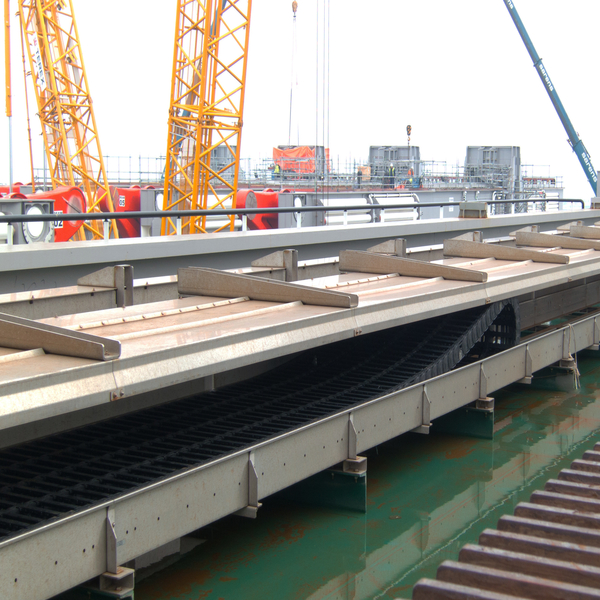

Data transmission in a crane system

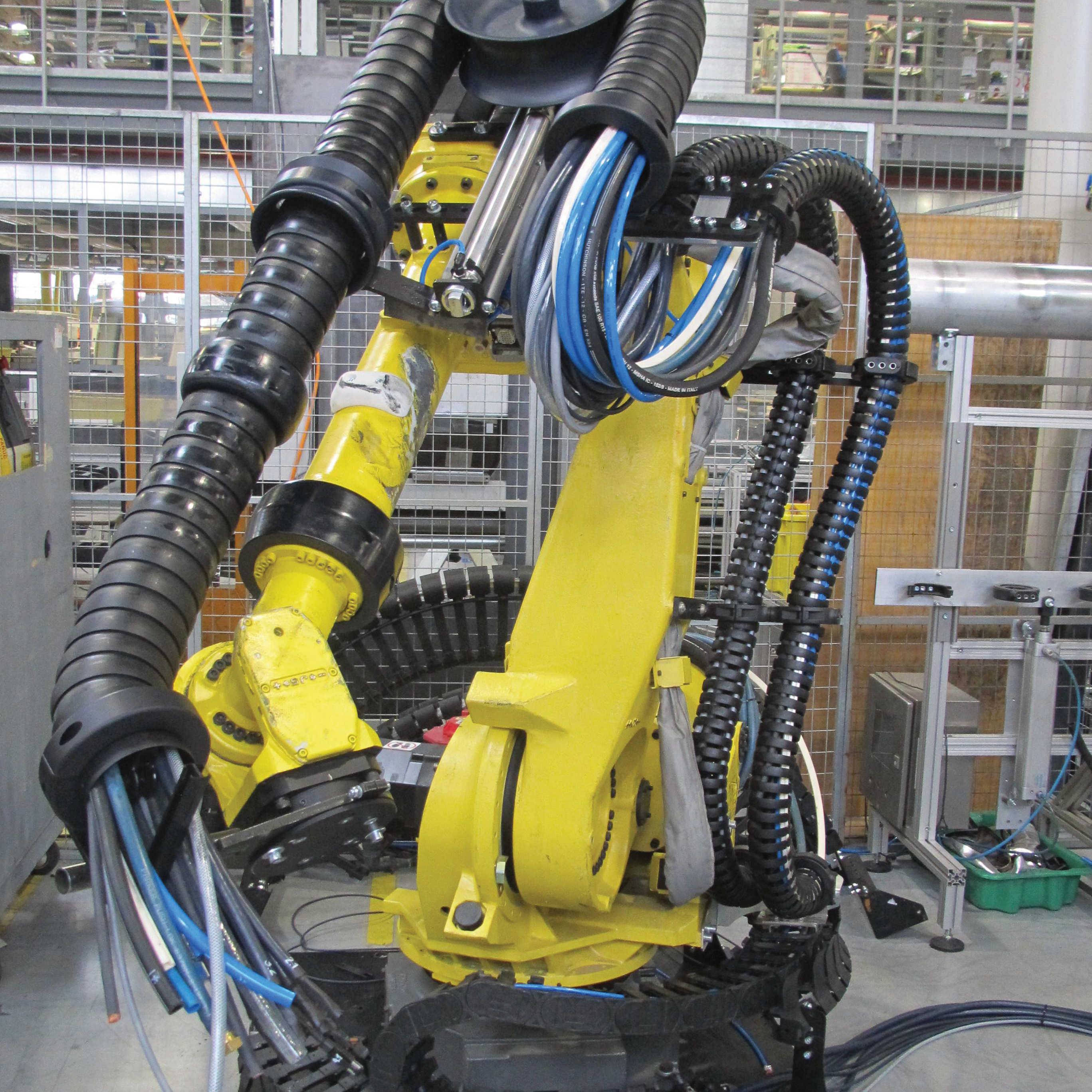

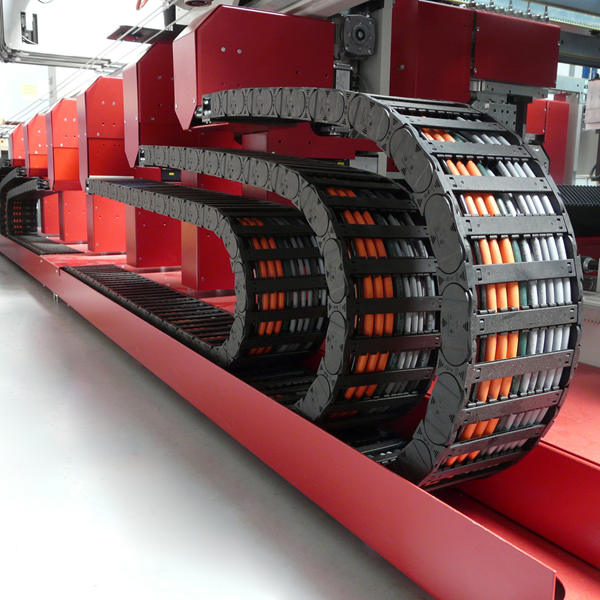

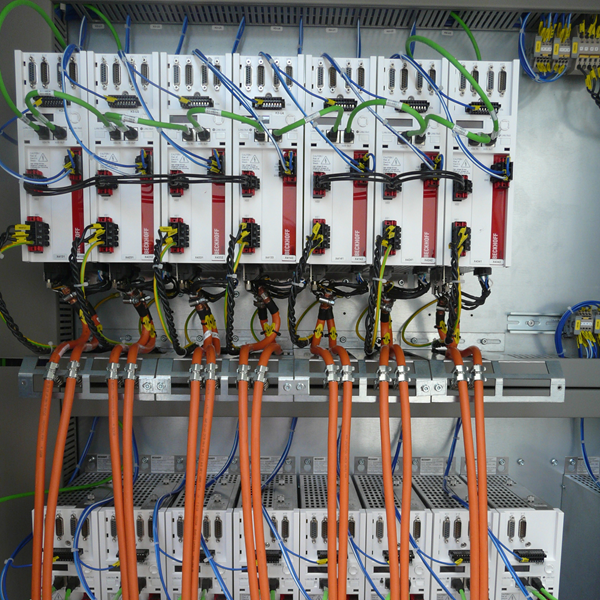

The importance of protecting cables has never been so pertinent as it is when cables are battling with the elements , elevated hundreds of feet in the air. igus® offers e-chain® systems that not only protect the cables but can inform you of defects.