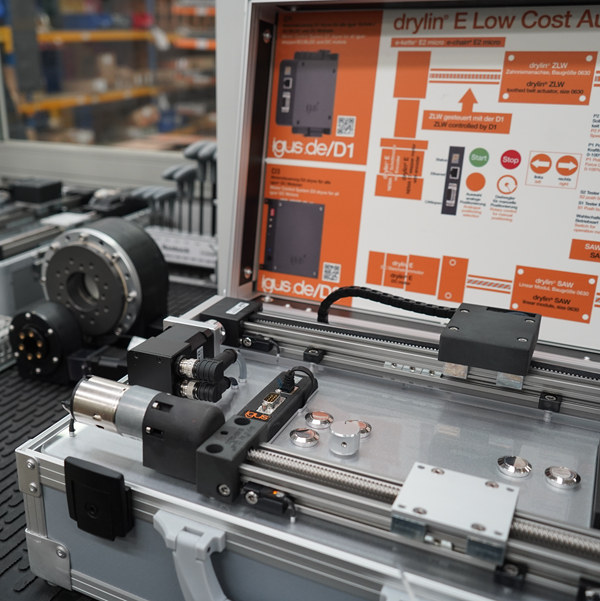

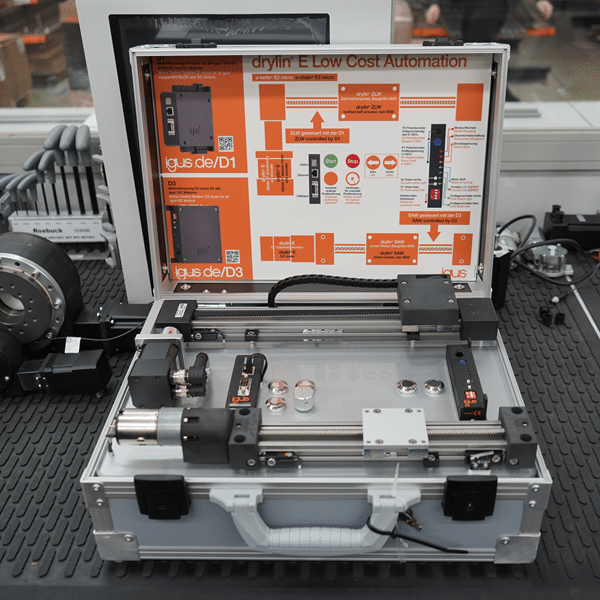

Flexible linear robots: where can I get one?

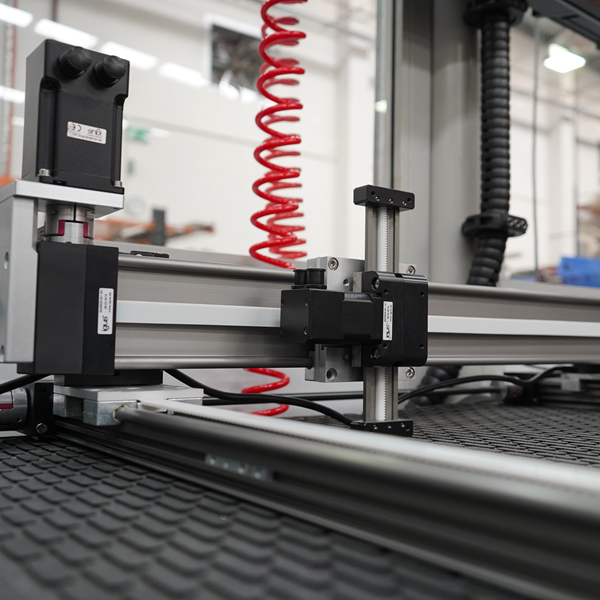

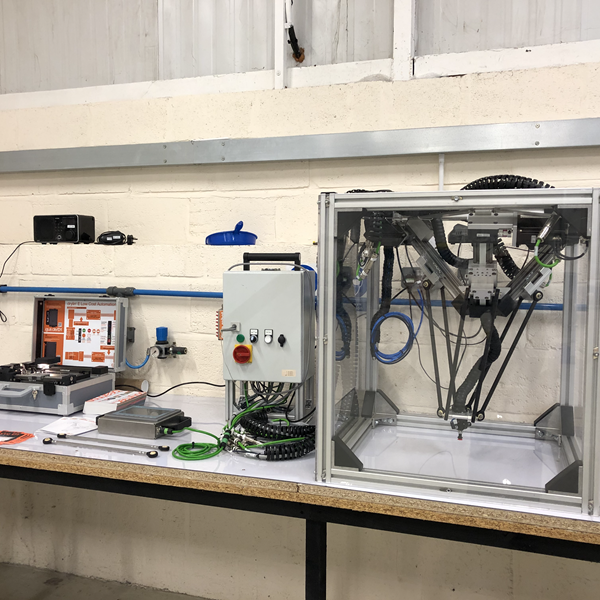

Multi-axis gantries are machinery systems that can travel across predefined surfaces or volumes. At igus®, we have gantry applications lifting hundreds of kilos for industrial tasks and others carrying out millimetres of travel for high precision tasks.