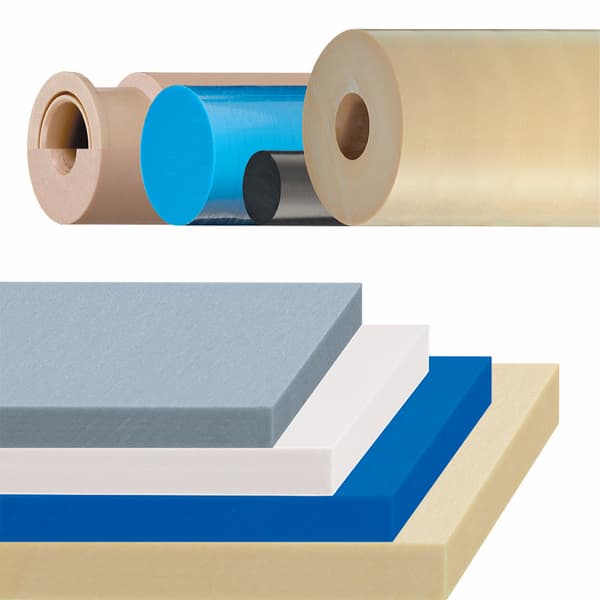

What are the main benefits of using polymer gears?

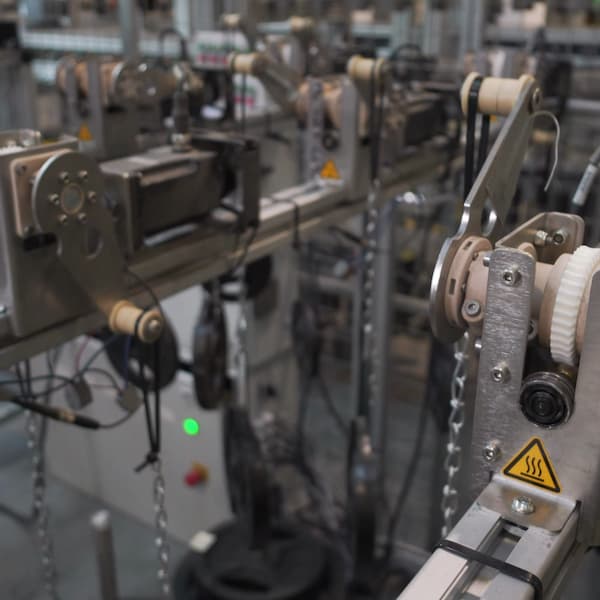

Polymer or plastic gears are fast becoming the new way of manufacturing gears. There are many positive attributes to using plastic gears such as cost saving, weight reduction and noise reduction. More and more industries are using them, are you?