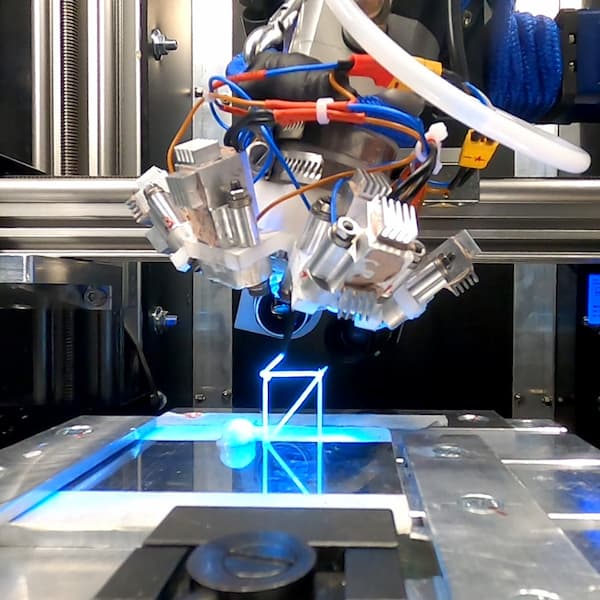

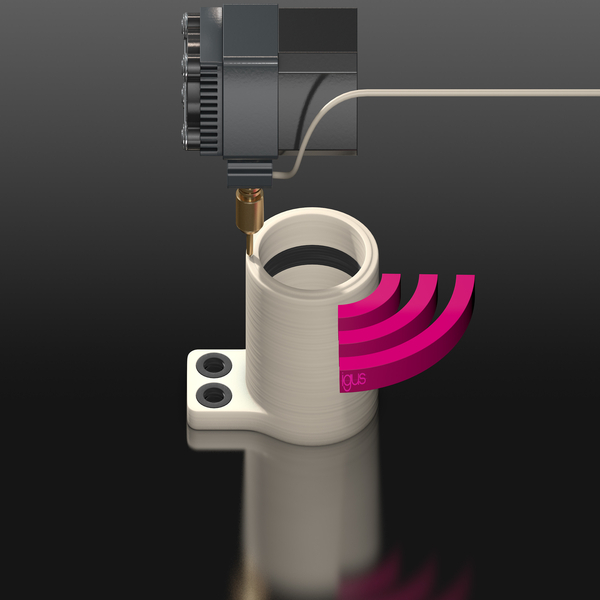

How to build a 3D printer with igus® parts

igus® provides designers of 3D printers with a large modular kit – linear technology, plain bearings, energy supply chains and lead screw systems – always completely lubrication-free. So, if you are building a 3D printer, talk to igus® and see how we can help with the build.