Motor controller? We’ve got you sorted!

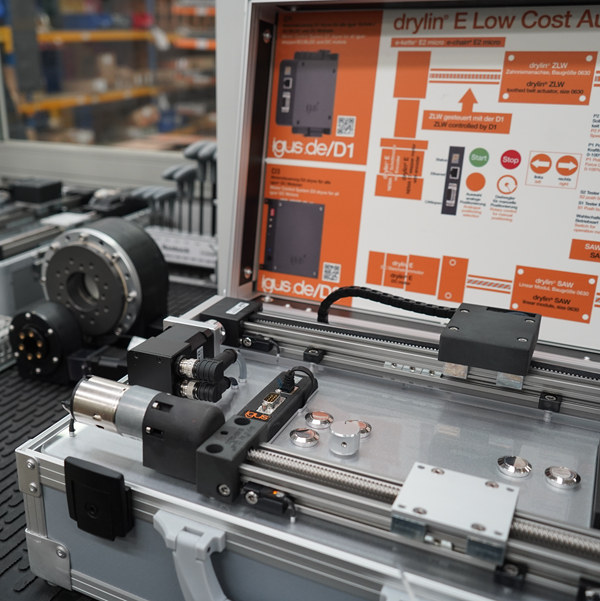

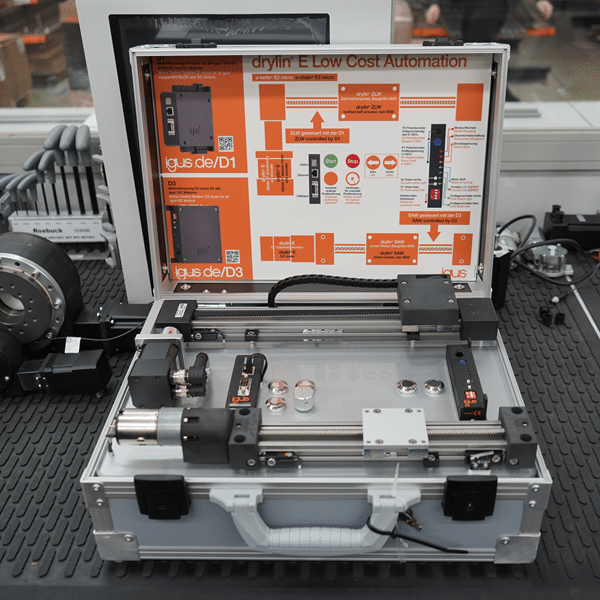

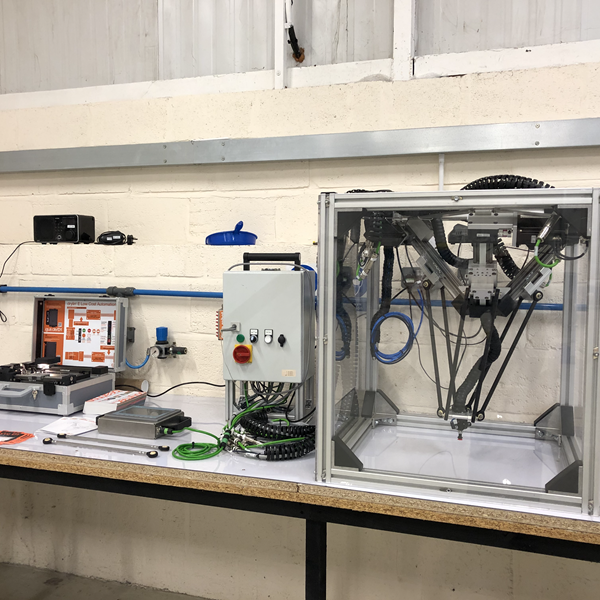

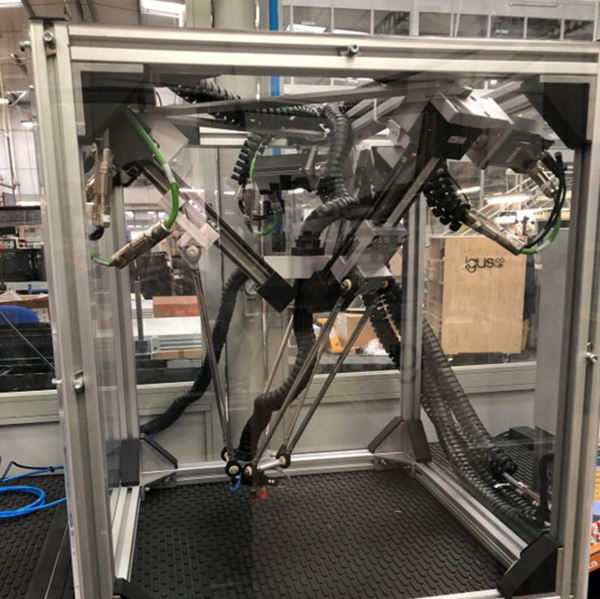

At igus® we love to shout about our software as much as our hardware: as the dryve D1® is both, it therefore creates no exception. The top features that we and our customers identify are: easy-to-use, accessible, versatile, low-cost, valuable and of course igus®-made.