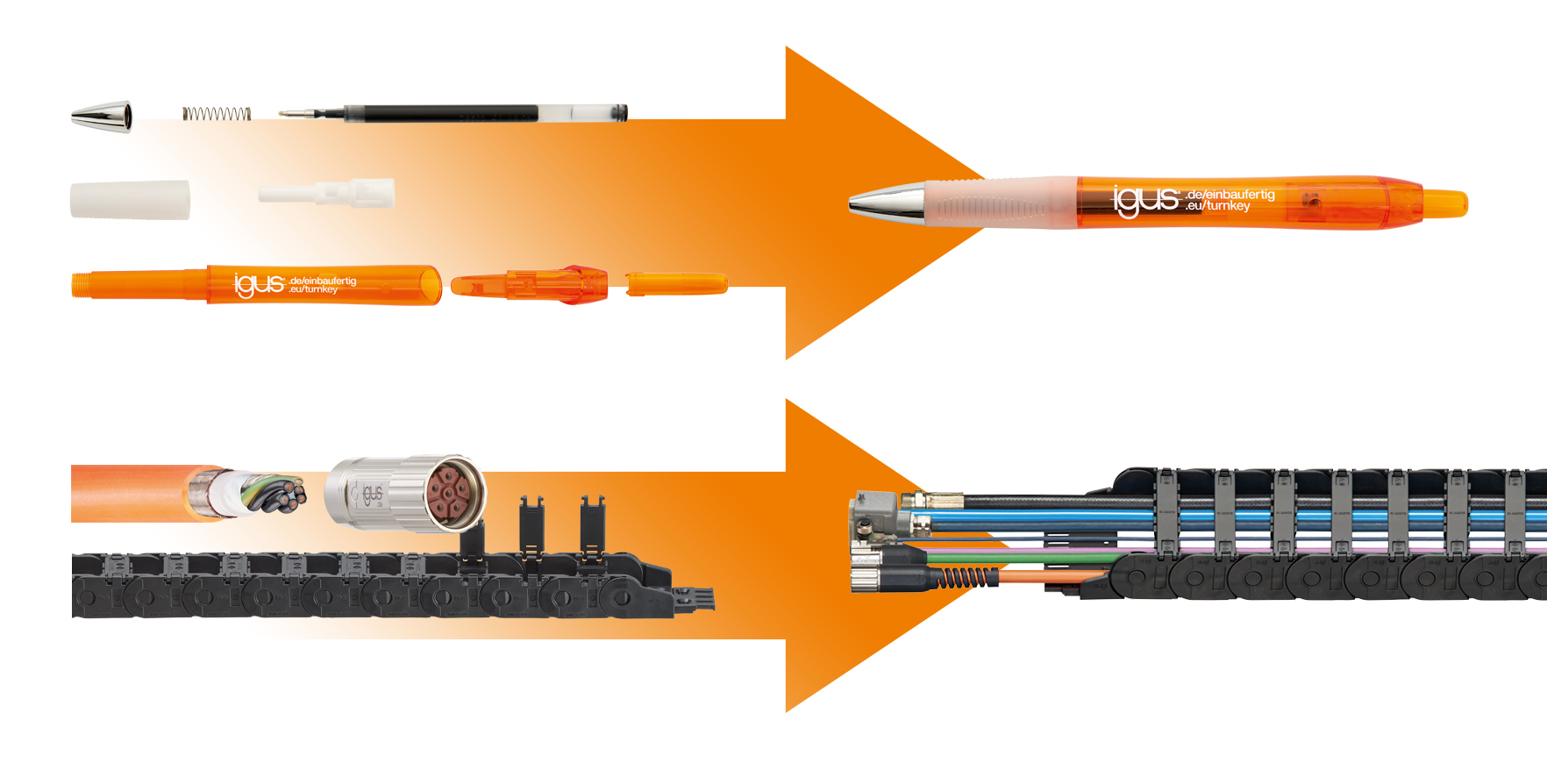

Configure, order and deliver without leaving your home or office

Keeping safe is igus’® top priority for both employees and customers. More and more of us are self isolating and working from home. This doesn’t mean that we can’t still help you. Find out how.