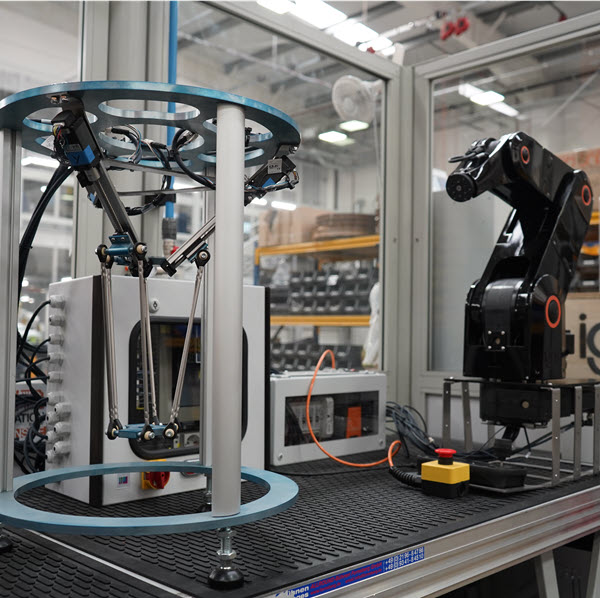

As the world pulls together, the 3D Print Product Manager at igus® goes one step further…..

The 3d Printing product manager , Dean Aylott wanted to do even more than he already was with his day to day work. igus® are already working alongside the NHS but Dean wanted to take this one step further and personally invested in a 3d printing machine. Here is how his 3d printing journey unfolded and how he is doing his bit to help our key workers.