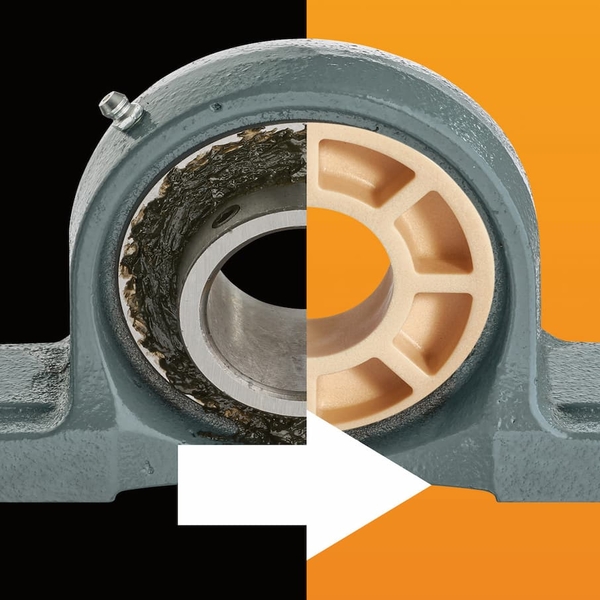

6 ball bearing materials you need to know about

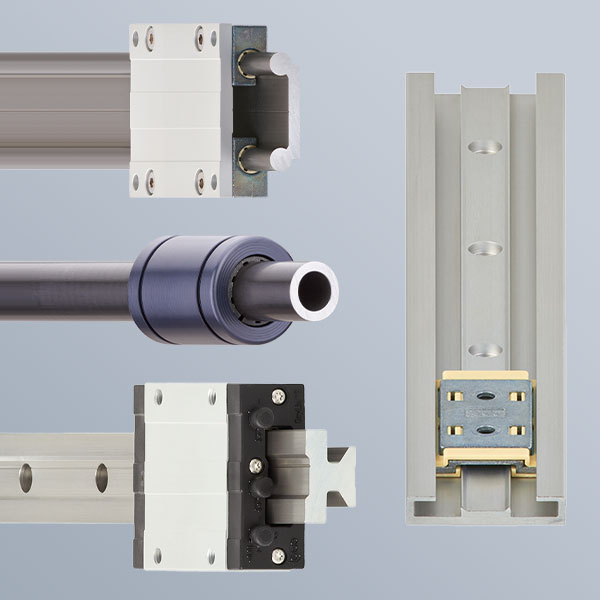

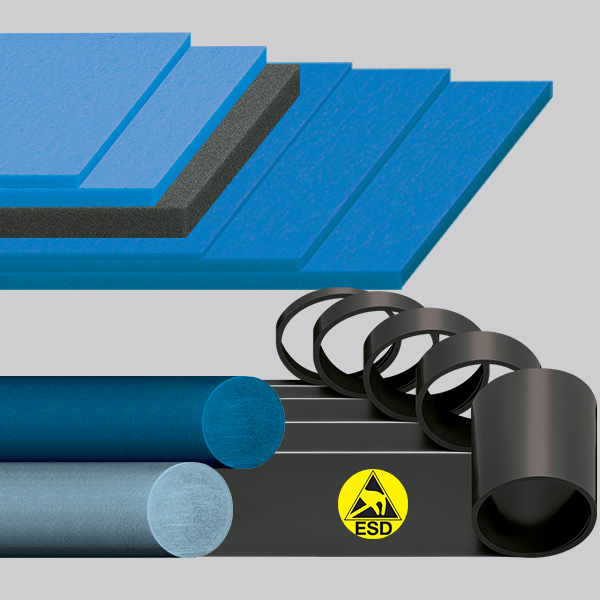

There is such a wide variety of ball bearings, metal, ceramic, plastic and all have variations of ball materials. This blog identifies some options that you have in regards to ball bearings. Which variation suits your requirements?